Alkaline blocking remover, preparation method thereof and alkaline blocking removal method in near-oil-well zone

A plugging agent and alkaline technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of well wall collapse, push up production costs, scrapping oil wells, etc., and achieve sand production serious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

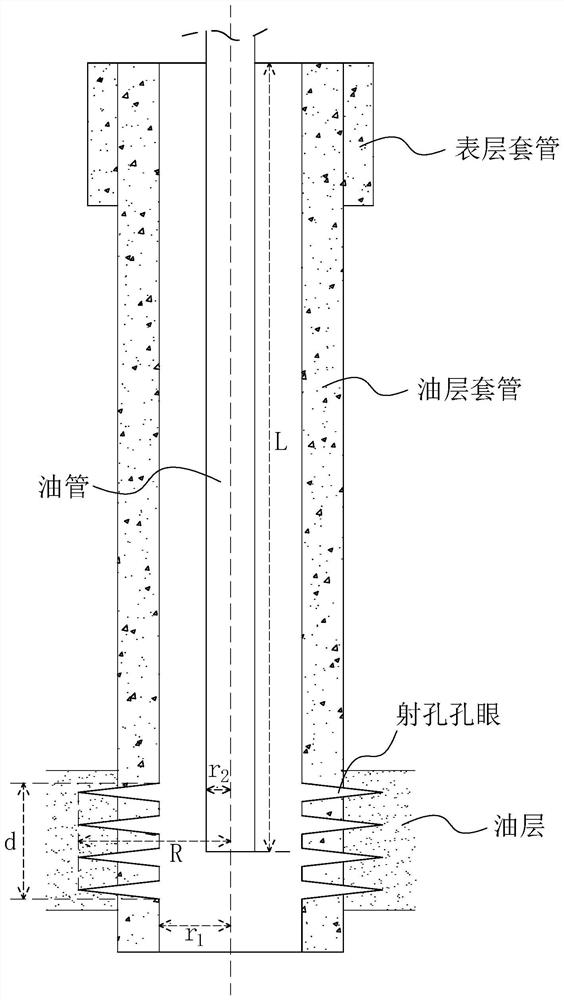

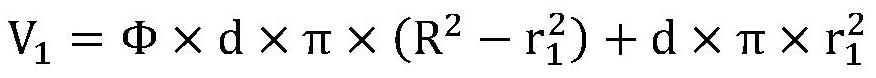

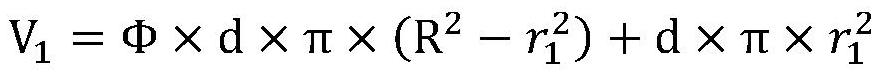

Method used

Image

Examples

Embodiment 11

[0081] Embodiment 11: Compared with Embodiment 4, the difference is that the tetrasodium salt of EDTA is replaced by acetic acid.

Embodiment 12

[0082] Embodiment 12: Compared with Embodiment 4, the difference is that tetrasodium EDTA is replaced by citric acid.

Embodiment 13

[0083] Embodiment 13: Compared with Embodiment 4, the difference is that the tetrasodium salt of EDTA is replaced by Sodium Isovitamin C.

[0084] The blocking removal rate of table 14 embodiment 11

[0085]

[0086]

[0087] The blocking removal rate of table 15 embodiment 12

[0088]

[0089] The blocking removal rate of table 16 embodiment 13

[0090]

[0091] It can be seen from Table 5 and Table 14-16 that, compared with the replacement of tetrasodium salt with acetic acid, citric acid and sodium isotretinoin, EDTA can slightly increase the plugging removal rate of alkaline plugging remover.

[0092] Table 17: Blockage removal rate of comparative examples 1-4

[0093]

[0094]

[0095] Table 18: Blockage removal rate of comparative example 1

[0096]

[0097] Table 19: The plugging removal rate of comparative example 2

[0098]

[0099] Table 20: Blockage removal rate of comparative example 3

[0100]

[0101] Table 21: The plugging removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com