Method for enriching copper and nickel from secondary nickel return material of copper smelting slag

A technology for copper smelting slag and return material, applied in the field of copper and nickel enrichment by secondary nickel return material in copper smelting slag, can solve problems such as economic loss, loss of nickel and copper metal, energy consumption and production cost increase, and achieve production cost The effect of energy saving and environmental protection, short production process and high metal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

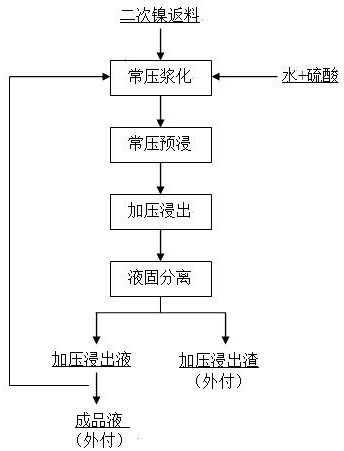

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] The invention discloses a method for enriching copper and nickel by secondary nickel return material of copper smelting furnace slag. The leaching solution enriched in nickel and copper is obtained through normal pressure pre-soaking and pressure leaching. The typical composition of the secondary nickel return material is: Ni: 14.94%, Cu: 22.14%, Co: 0.45%, Fe: 11.02%, S: 1.27%, Si: 18.76%.

[0015] Described technological process comprises the following steps:

[0016] S1, Atmospheric pressure slurrying: Mix the sulfuric acid solution with an acidity of 10g / l and the secondary nickel return material at a mass ratio of 5:1 for atmospheric pressure slurrying, the slurrying temperature is 35°C, and the slurrying time is 2 hours;

[0017] S2, Atmospheric pressure presoaking: Send the slurried pulp into the normal pressure reaction tank, control the presoaking temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com