Hydrogen production method, hydrogen production system, and circulating method and circulating device of hydrogen production electrolyte

A circulation device and electrolyte technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problem of low hydrogen purity, achieve the effect of improving hydrogen purity, reducing hydrogen volume, and high system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

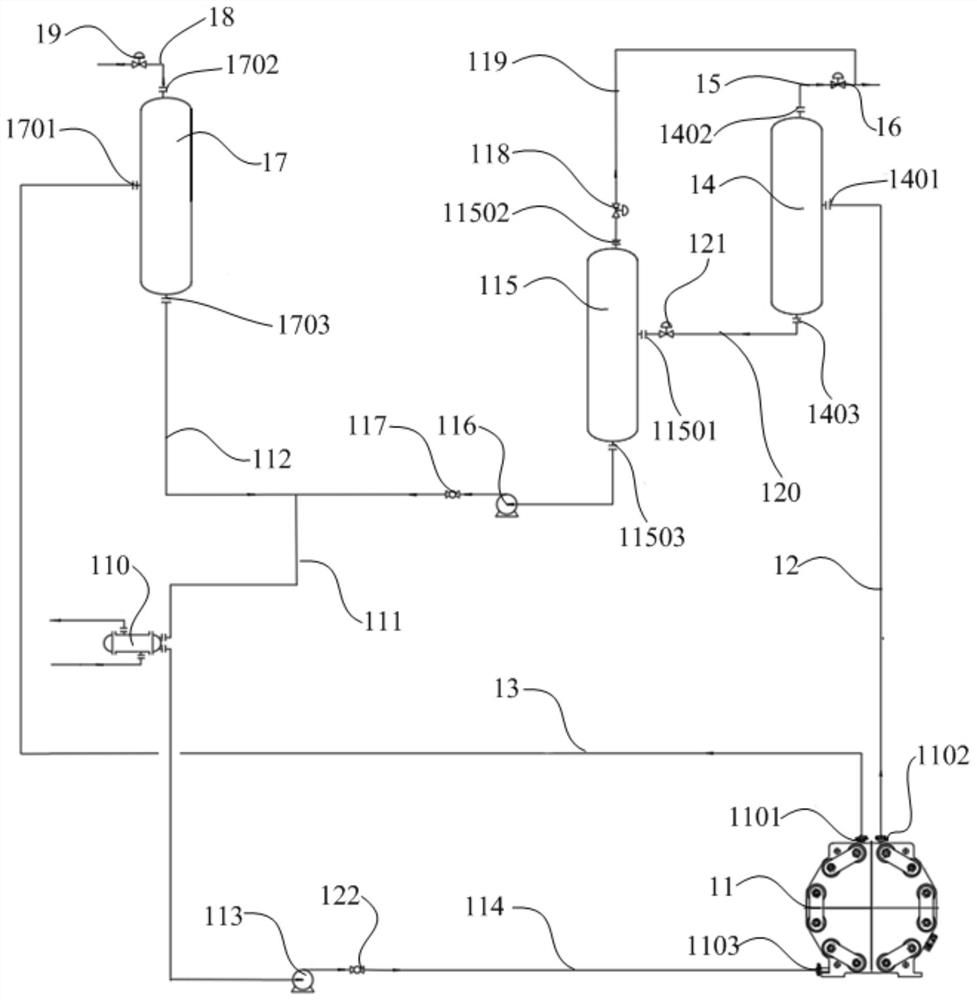

[0168] Such as figure 1 As shown, the hydrogen production electrolyte circulation device provided in Embodiment 1 includes an oxygen-side electrolyte circulation device. Specifically, the above-mentioned circulation device for hydrogen production electrolyte includes: hydrogen side gas-liquid separation device 17, oxygen side gas-liquid separation device 14, oxygen side step-down gas-liquid separation device, oxygen side booster device, oxygen side delivery device, oxygen side side cooling device 110, and a controller.

[0169] Specifically, there are two oxygen-side pressure boosting devices, namely a first oxygen-side pressure boosting device and a second oxygen-side pressure boosting device; the first oxygen-side pressure boosting device is located upstream of the oxygen-side cooling device 110, and the second oxygen-side pressure boosting The side boost device is located downstream of the oxygen side cooling device 110 . During the cycle, the first oxygen-side pressure b...

Embodiment 2

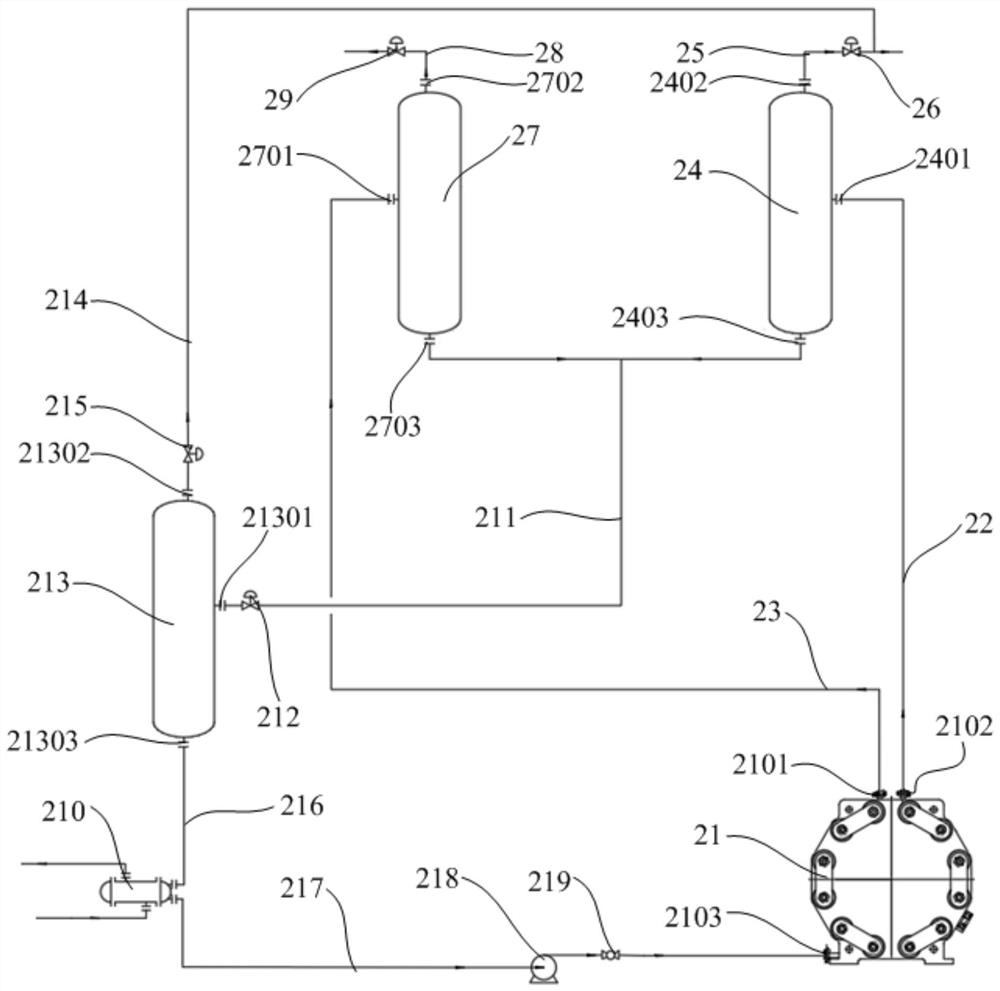

[0180] Such as figure 2 As shown, the hydrogen production electrolyte circulation device provided in the second embodiment includes an oxygen-side electrolyte circulation device and a hydrogen-side electrolyte circulation device. Specifically, the circulation device for the hydrogen-producing electrolyte includes: a hydrogen-side gas-liquid separation device 27, an oxygen-side gas-liquid separation device 24, an oxygen-side step-down gas-liquid separation device, a hydrogen-side step-down gas-liquid separation device, an oxygen-side booster Pressure device, oxygen side delivery device, hydrogen side booster device, hydrogen side delivery device, oxygen side cooling device, hydrogen side cooling device, and controller.

[0181] The above-mentioned oxygen-side step-down gas-liquid separation device and the hydrogen-side step-down gas-liquid separation device are the same step-down gas-liquid separation device, specifically, the step-down gas-liquid separation device includes a ...

Embodiment 3

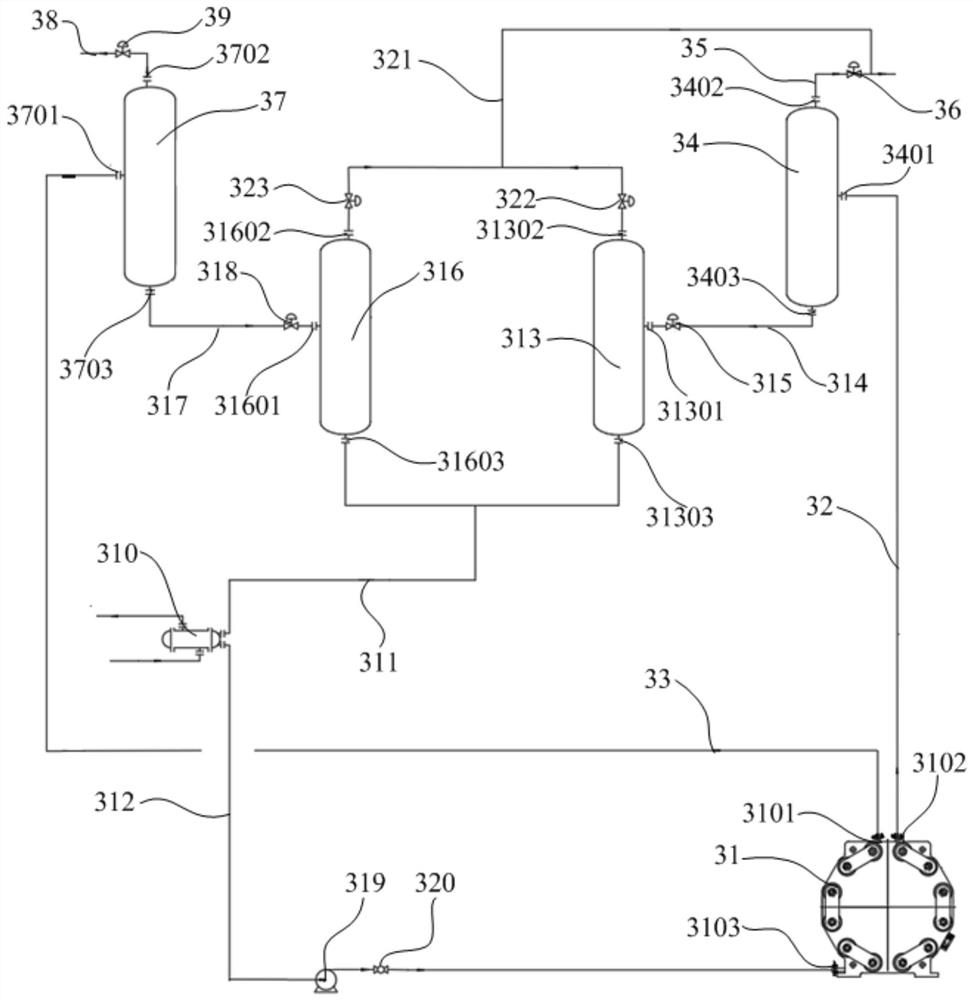

[0193] Such as image 3 As shown, the hydrogen production electrolyte circulation device provided in the third embodiment includes an oxygen-side electrolyte circulation device and a hydrogen-side electrolyte circulation device. Specifically, the circulation device for the above-mentioned hydrogen production electrolyte includes: a hydrogen-side gas-liquid separation device 37, an oxygen-side gas-liquid separation device 34, an oxygen-side step-down gas-liquid separation device, a hydrogen-side step-down gas-liquid separation device, an oxygen side booster Pressure device, oxygen side delivery device, hydrogen side booster device, hydrogen side delivery device, oxygen side cooling device, hydrogen side cooling device, and controller.

[0194] The above-mentioned oxygen-side step-down gas-liquid separation device includes an oxygen-side flasher 313 and an oxygen-side decompression valve 315 arranged on the inlet pipe of the oxygen-side flasher 313, and the above-mentioned hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com