Construction method of ultra-large-span double-high-vanadium-cable curved surface beam string

A construction method and high-vanadium technology, applied in special structures, building materials processing, building components, etc., can solve problems such as structural deformation, affecting installation quality, and weak structural rigidity, so as to achieve a solid foundation, meet on-site construction requirements, and ensure The effect of installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

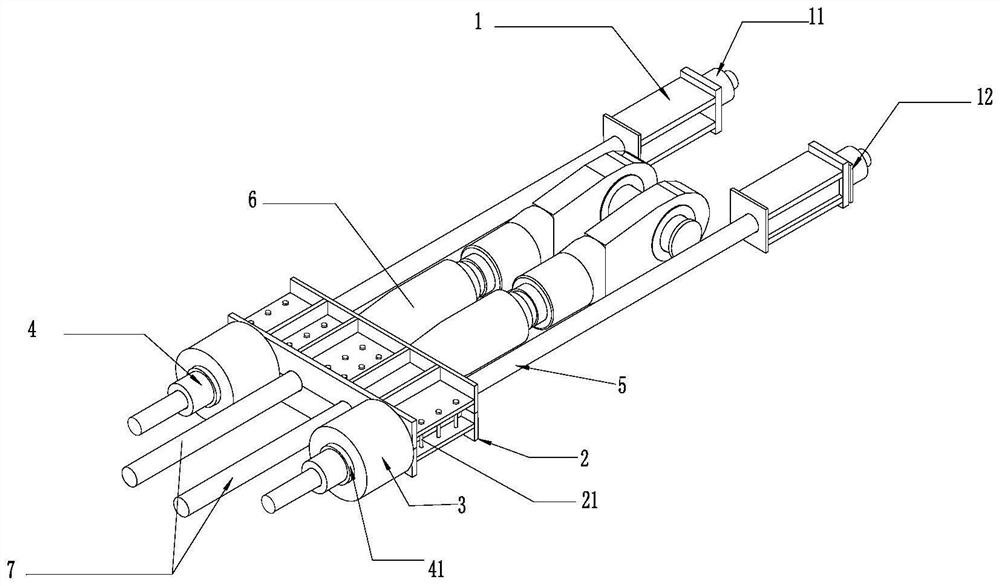

Image

Examples

Embodiment Construction

[0028] The invention will be further described below in conjunction with the accompanying drawings.

[0029] A construction method for a super-large-span double-high vanadium cable curved surface string beam, specifically comprising the following steps:

[0030] a. Carry out simulation analysis and check calculation on the construction process;

[0031] The simulation analysis adopts the structural design software midas gen 2018 finite element program simulation analysis, and analyzes the installation process of the tension string beam and the analysis of the tension construction composition respectively.

[0032] b. Install the steel frame and support frame according to the analysis and calculation results:

[0033] According to the building structure, processing and transportation requirements and on-site working conditions, BIM technology is used to select the section and section of the string beam and the type of hoisting equipment; then install the steel frame and suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com