Radial plunger pump

A plunger pump and plunger technology, applied in the field of radial plunger pump, can solve the problems of large vibration, poor stability and poor dynamic balance of plunger pump, so as to reduce production and maintenance costs and improve oil absorption efficiency , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

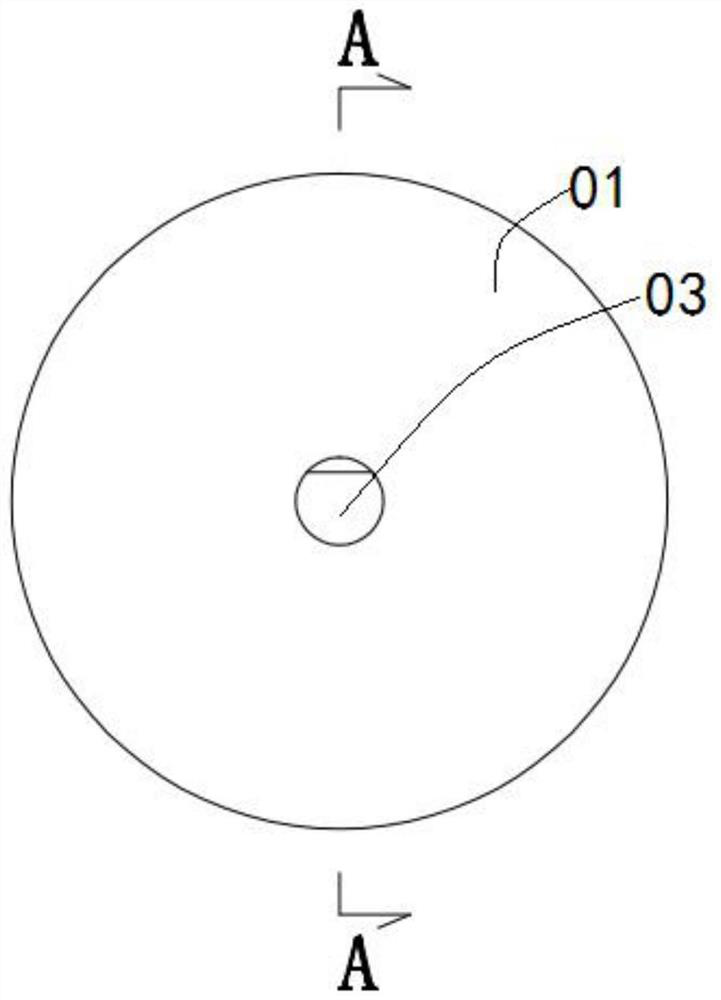

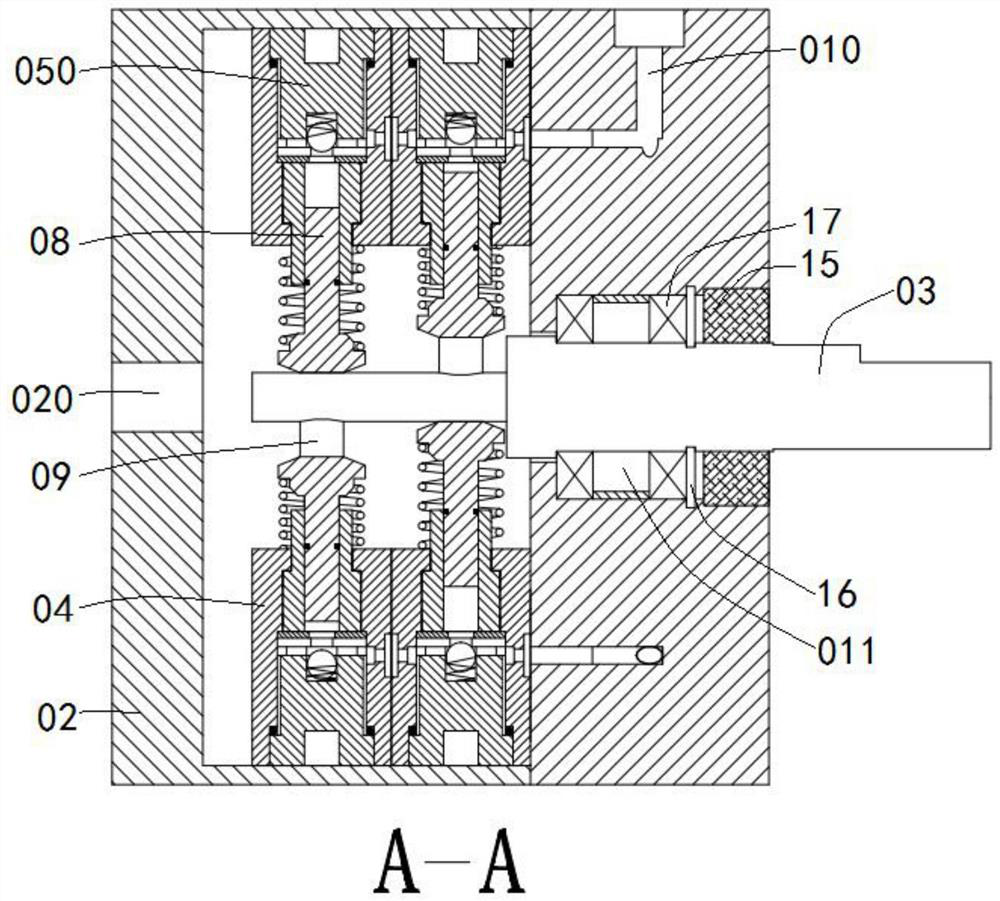

[0030] See attached Figure 1-9 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The present invention specifically discloses a radial plunger pump, including: a pump body 01, a rear cover 02, a rotating shaft 03, and a plunger mechanism. The pump body 01 as a whole It is cylindrical and has an oil outlet channel 010 inside. The oil outlet channel 010 has an inlet and an outlet. The inlet penetrates to one end wall of the pump body 01, and the outlet penetrates to the outer wall of the pump body 01. The back cover 02 is sealed and buckled on the pump body. One end surface of the pump body 01 and defines a sealed cavity with it, the rotating shaft 03 coaxially runs through the two ends of the pump body 01 and the two are rotationally connected;

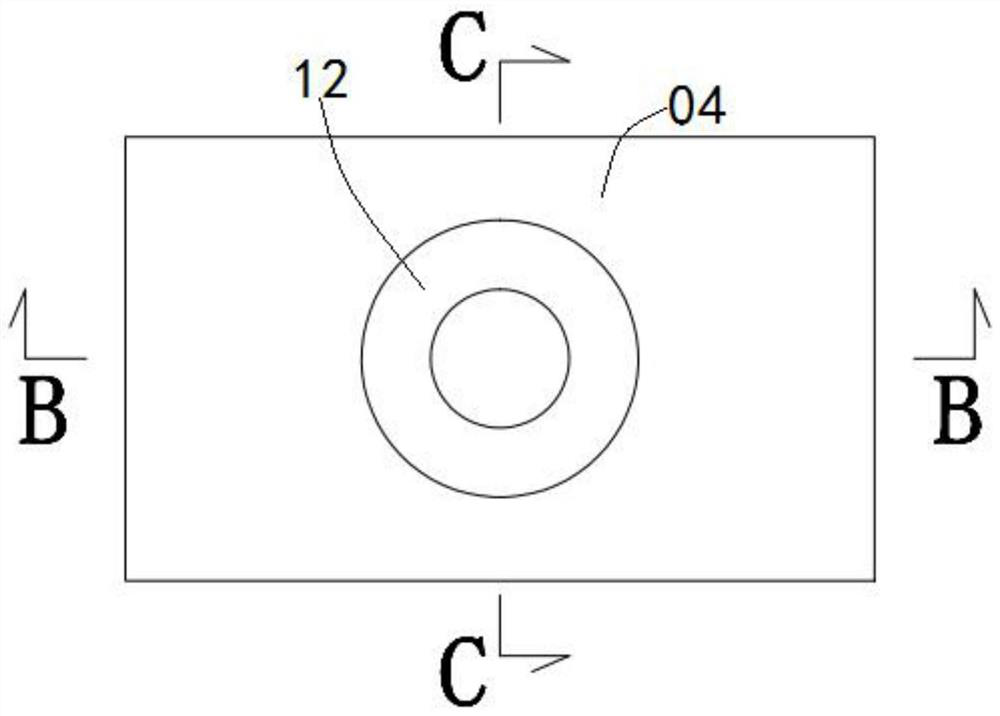

[0031] The plunger mechanism is installed in the sealing chamber and includes a valve block 04, an oil outlet check valve 05, a plunger sleeve 06, an oil inlet check valve 07 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com