Method for etching and forming ITO substrate of liquid crystal screen

A molding method and liquid crystal screen technology, applied in the directions of optics, instruments, electrical components, etc., can solve problems such as low efficiency, substrate damage, and high labor costs, so as to improve the efficiency of film removal, avoid damage, and reduce processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

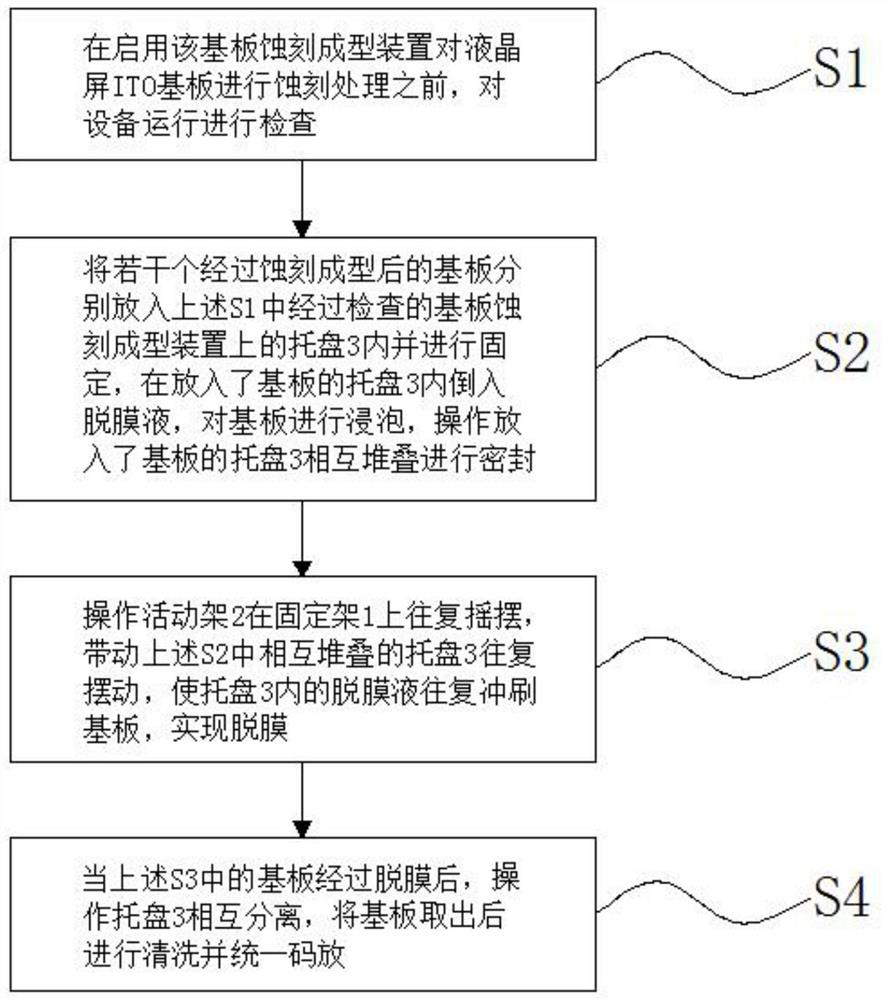

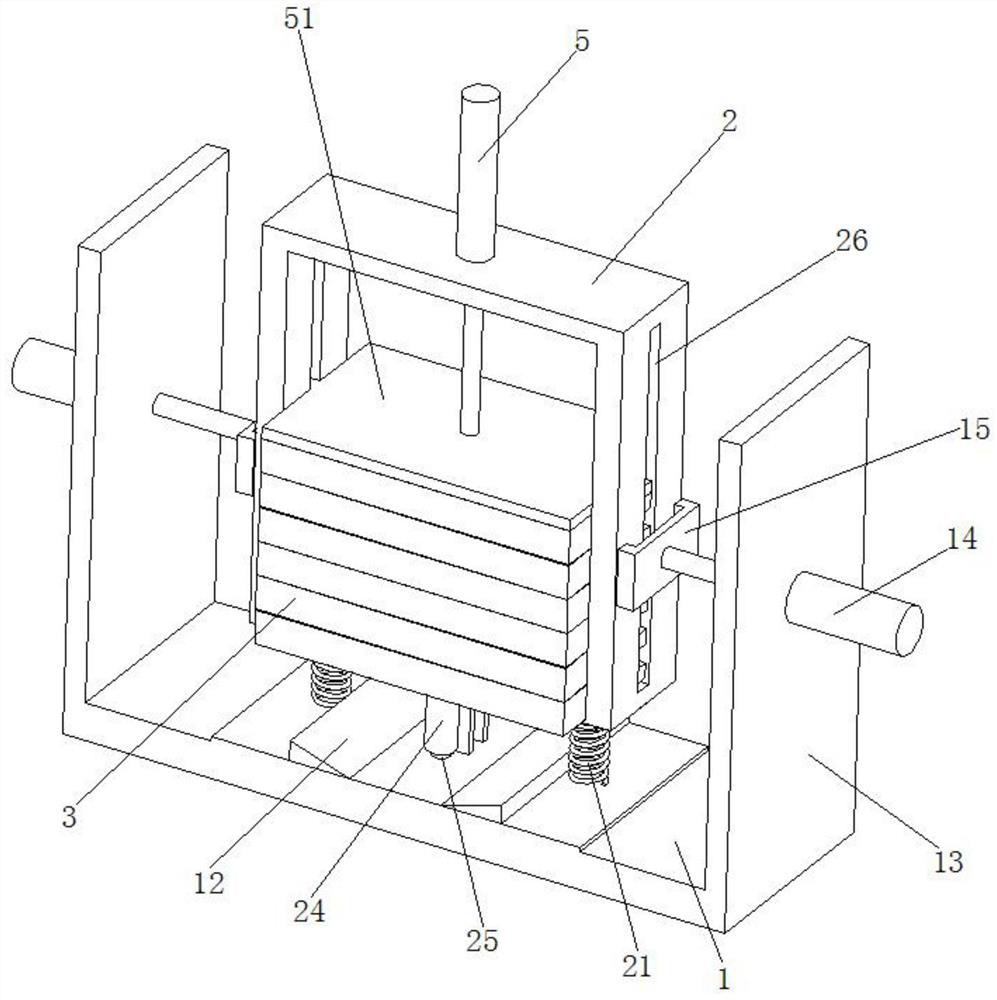

[0035] like Figure 1 to 11 As shown, a liquid crystal screen ITO substrate etched forming method, which uses a substrate etching forming device including a fixing frame 1, a movable frame 2 and a tray 3, and the substrate etching forming means pair LCD screen ITO The specific method is as follows when the substrate is etched.

[0036] S1, device check: Check the device operation before etching the liquid crystal screen ITO substrate before enabling the substrate etching forming device;

[0037]S2, placed in the substrate: the plurality of etched forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com