Industrial energy-saving and environment-friendly dust removal device

A technology of energy saving and environmental protection, dust removal device, applied in the direction of heat exchanger type, dispersed particle filtration, heat exchanger, etc., can solve the problems of energy waste and inability to realize waste heat recovery and utilization of flue gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

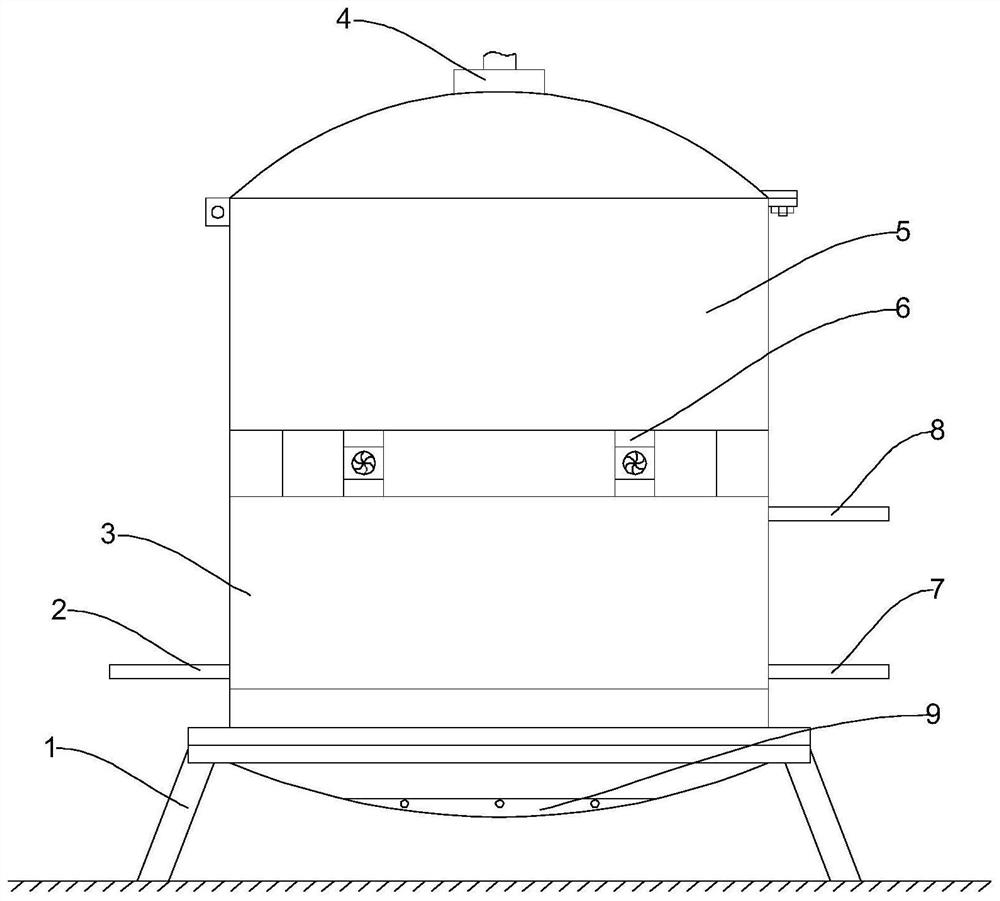

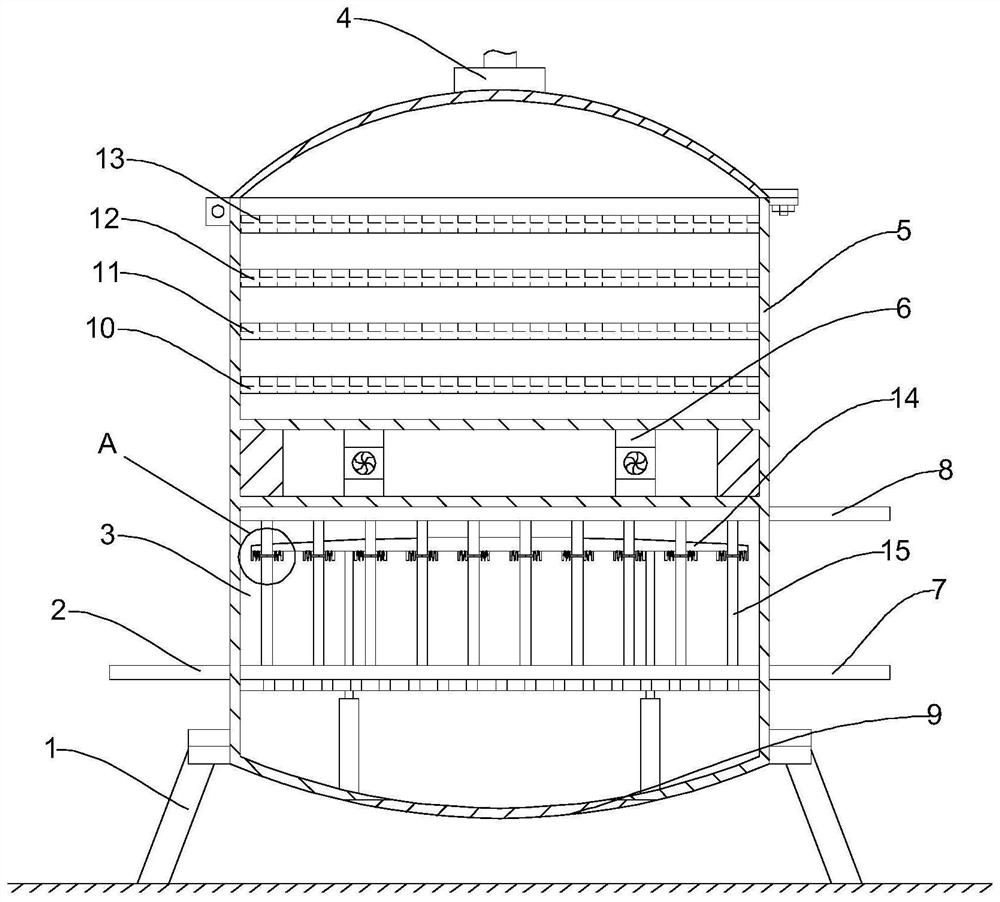

[0036] Please refer to Figure 1-Figure 3 , the present embodiment provides an industrial energy-saving and environment-friendly dust removal device, comprising:

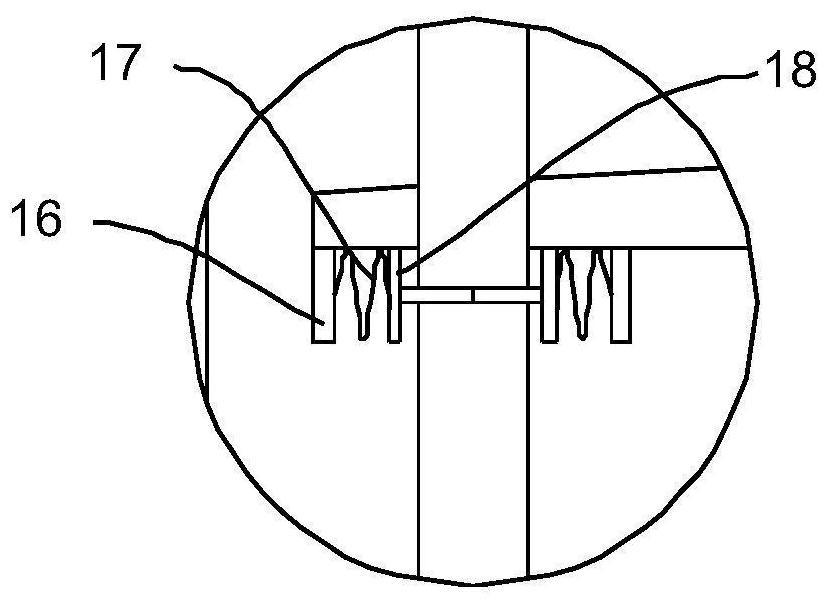

[0037] The heat exchange assembly, the heat exchange assembly includes a heat exchange box 3, the heat exchange box 3 is provided with a flue gas inlet pipe 2 and a flue gas outlet pipe 6 communicating with its inner cavity, the heat exchange box 3 is provided with a heat exchange tube, Both ends of the above-mentioned heat exchange tubes pass through the outside of the above-mentioned heat exchange box 3;

[0038] The dust removal assembly, the dust removal assembly includes a dust removal box 5, the dust removal box 5 has an inlet and an outlet, the inlet of the dust removal box 5 communicates with the opening end of the flue gas outlet pipe 6, and the dust removal box 5 is arranged along the direction from the inlet to the outlet. A filter net and an activated carbon adsorption net 12 are arranged in sequence. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com