Wireless dust collector protection plate test system

A testing system and technology for vacuum cleaners, which are applied in the directions of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of cleaning only one protective plate at a time, labor-intensive, low efficiency, etc. The effect of labor loss and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

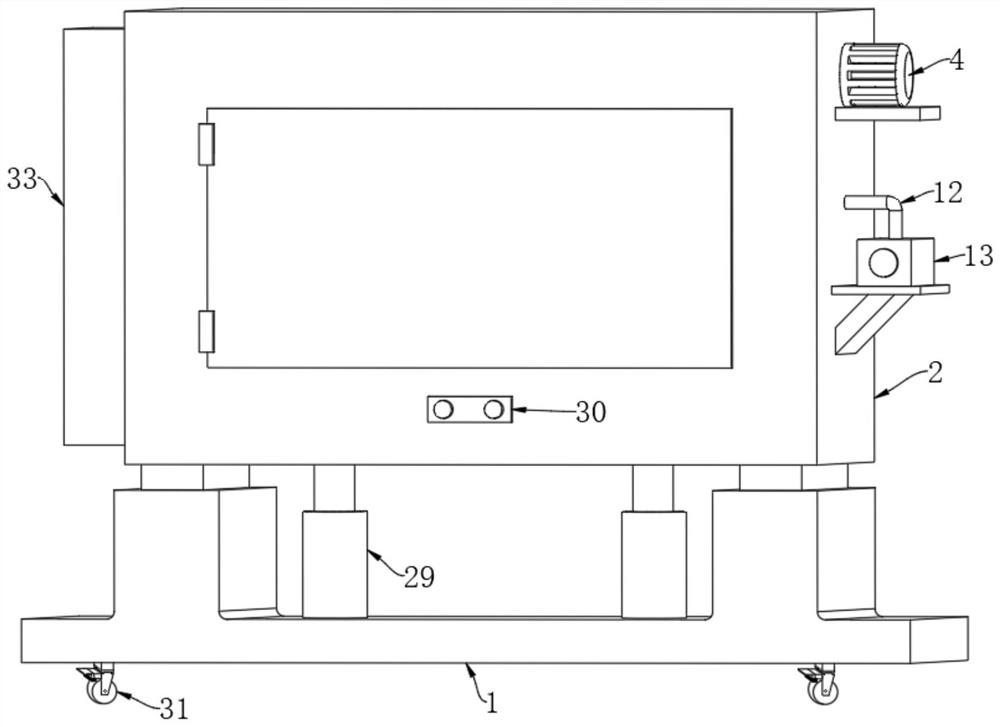

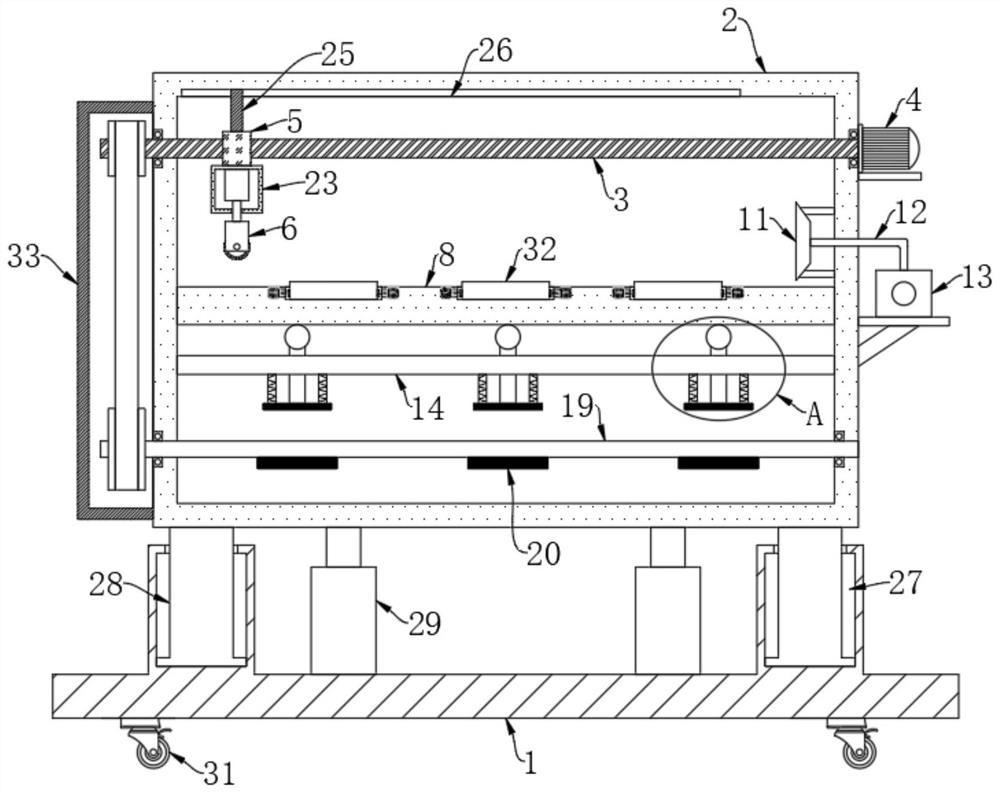

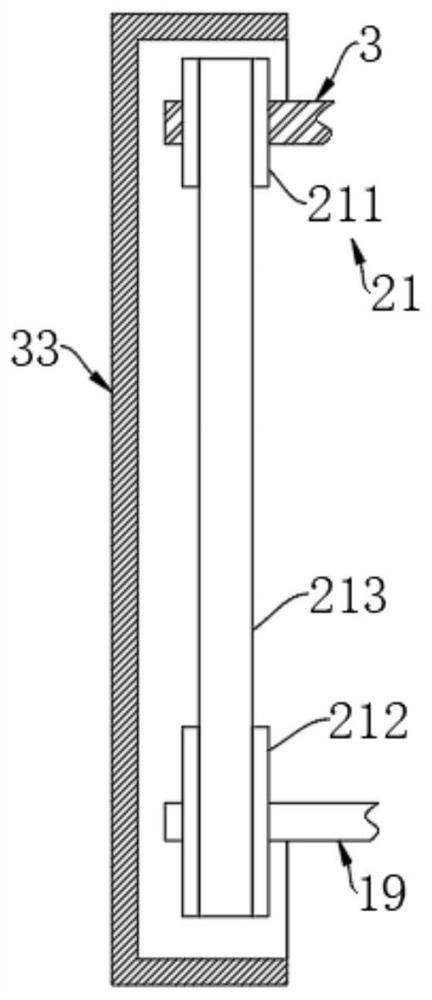

[0030] Such as Figure 1-7 As shown, a wireless vacuum cleaner protection board testing system includes a support base 1, a plurality of universal wheels 31 are fixedly connected to the lower end of the support base 1, and the universal wheels 31 can be self-locking, and the setting of the universal wheels 31 is convenient for use Those who move the whole device, the support seat 1 is fixedly connected with the dust removal box 2, and the support seat 1 is provided with two sliding chambers 27, and the sliding chamber 27 is slidably connected with a sliding seat 28, and the upper end of the sliding seat 28 is fixed with the dust removal box 2. connection, two cylinders 29 are arranged on the support base 1, and the output ends of the cylinders 29 are fixedly connected with the dust removal box 2, and the height of the dust removal box 2 can be adjusted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com