A powder continuous feeder and method thereof

A powder and feeder technology, which is applied in the field of powder continuous feeder, can solve the problems of unsteady screening system and separation of powder and air, and achieve the effect of simple structure and preventing the air pressure from being too high or too low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

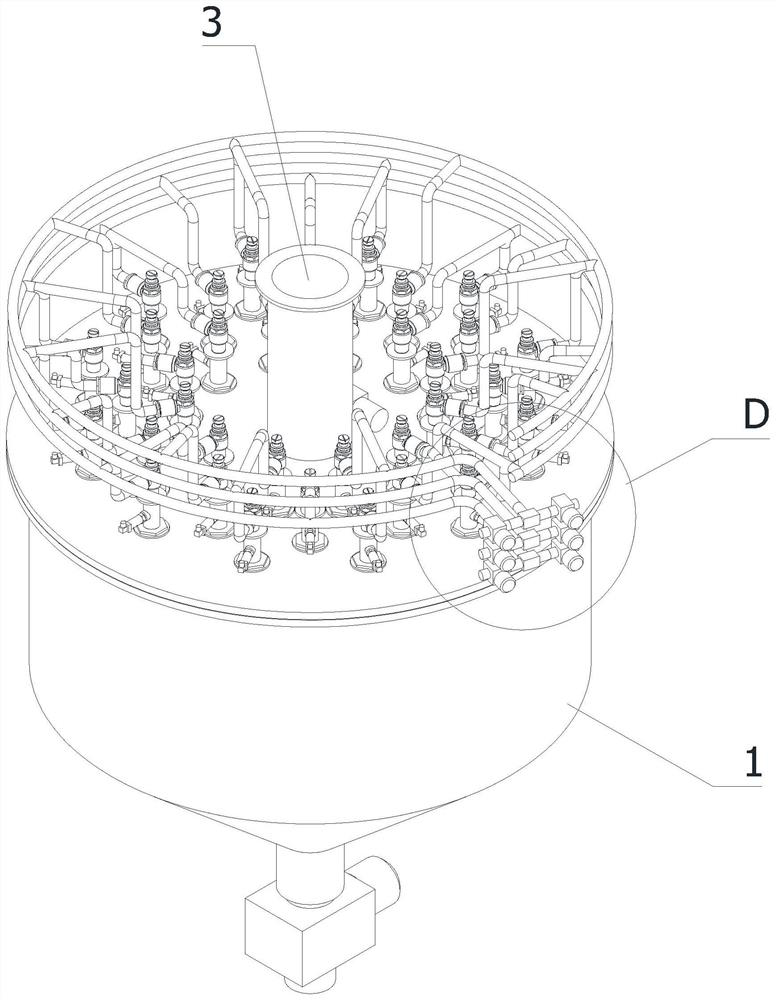

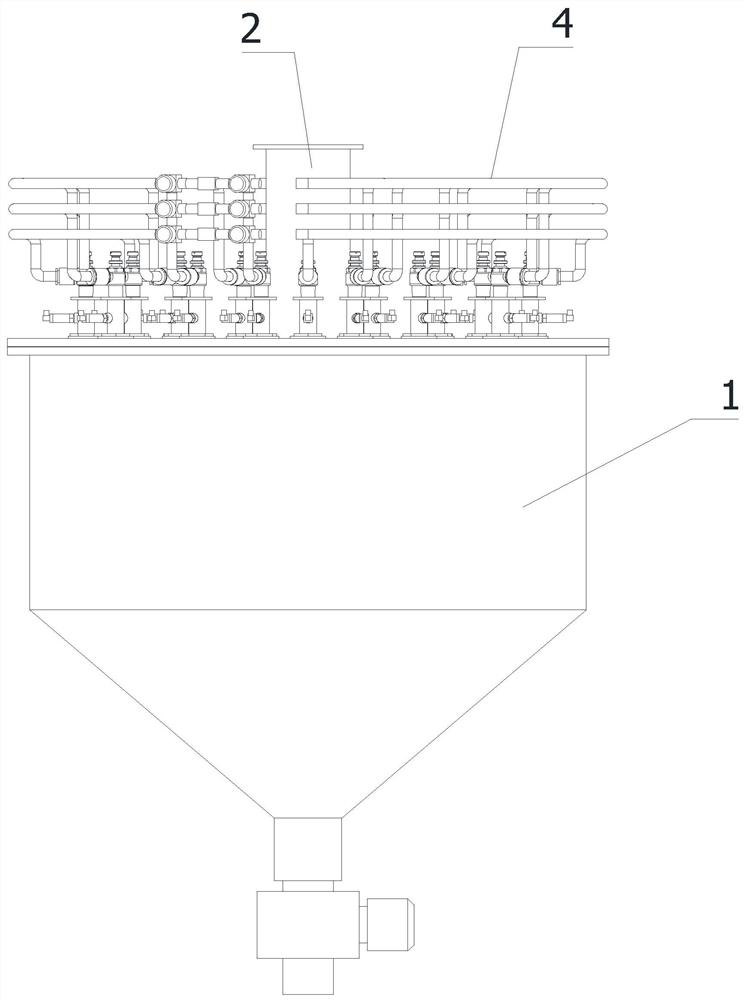

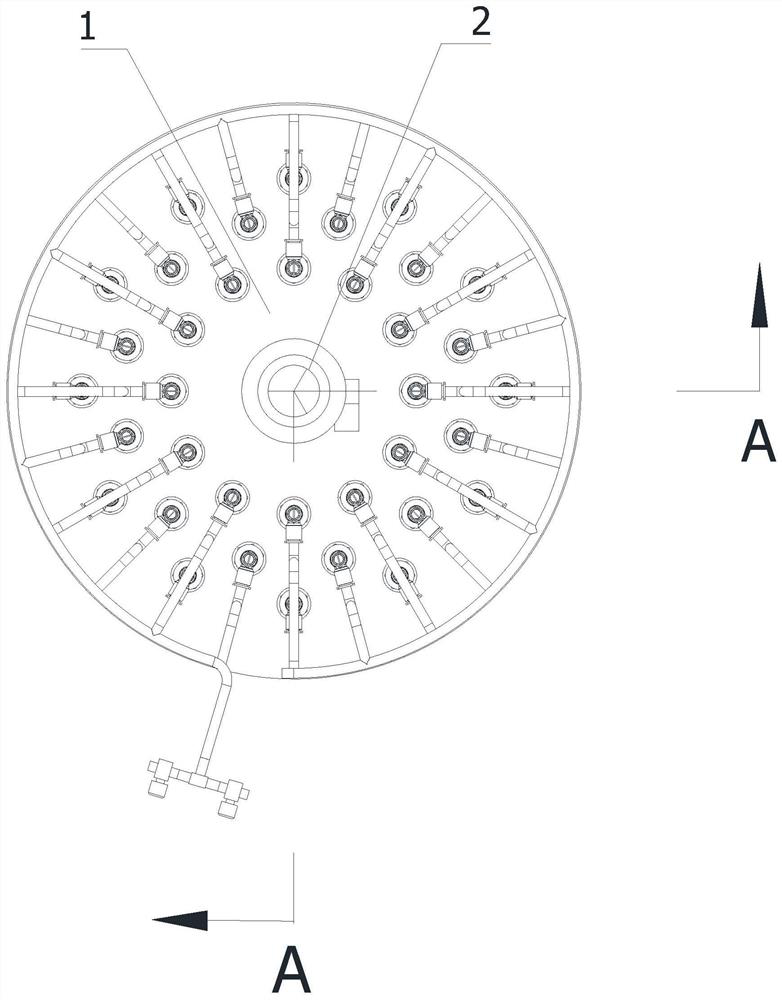

[0056] In order to solve the technical problem that the existing powder feeder cannot continuously and stably separate powder and air, such as Figure 5 As shown, the following technical solutions are provided:

[0057] A powder continuous feeder, comprising,

[0058] Material tank 1, the bottom end of the material tank 1 is provided with a blanking port 1a coaxial with it;

[0059] Feeding assembly 2, the feeding assembly 2 is arranged on the feeding tank 1, and the discharge port of the feeding assembly 2 is located at the top of the feeding tank 1, and the feeding assembly 2 discharges The mouth faces the inner wall of the material tank 1 in the radial direction;

[0060] A material suction member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com