A prefabricated planted concrete wall panel for sand and dust areas

A planting concrete and prefabricated technology, applied in the field of building wall panels, can solve problems such as unsafe, ineffective dust prevention and noise reduction, poor dust treatment effect, etc., and achieve the effect of not being easy to seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

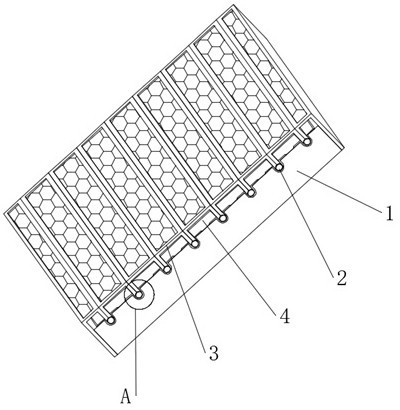

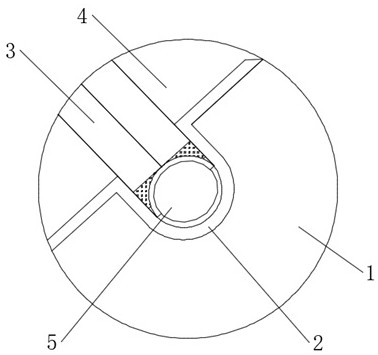

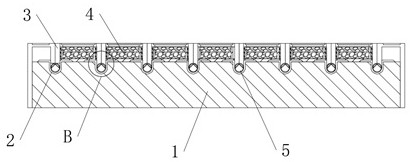

[0045] see Figure 1-3 A kind of prefabricated planting concrete wall panel used in dusty areas, including a prefabricated wall panel main body 1, the prefabricated wall panel main body 1 needs to have a certain inclination angle during installation and the semi-permeable drainage pipe 5 is installed from top to bottom, technicians can according to The water supply pipe needs to be connected to the semi-permeable drain pipe 5, and the semi-permeable drain pipe 5 is filled with water by passing high-pressure water into the semi-permeable drain pipe 5 so that the water overflows from the semi-circular permeable pipe 502 to make the bottom of the planting block 4 To absorb the overflowing water flow and realize the water supply of the planting block 4, the main body 1 of the prefabricated wall panel is provided with a plurality of evenly distributed strip grooves, and the reinforcement strips 2 are fixedly connected in the strip grooves, and the two adjacent reinforcement strips 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com