Combined pile drill rod, drilling tool and combined pile manufacturing method

A technology of composite piles and drill pipes, which is applied in the field of drilling tools, composite piles, and composite pile drill pipes. It can solve problems such as concentricity control, slow down construction speed, and affect construction efficiency. The effect of high speed and high coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

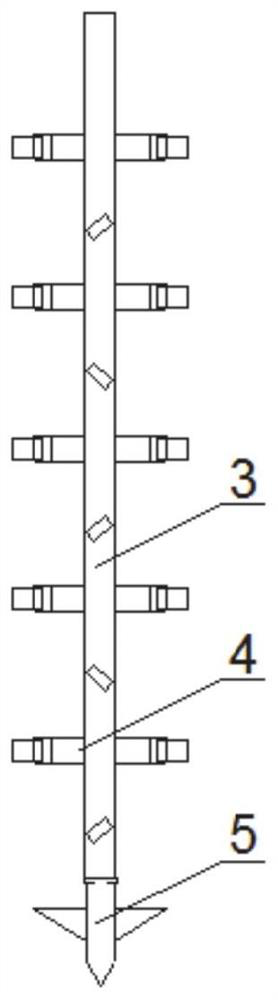

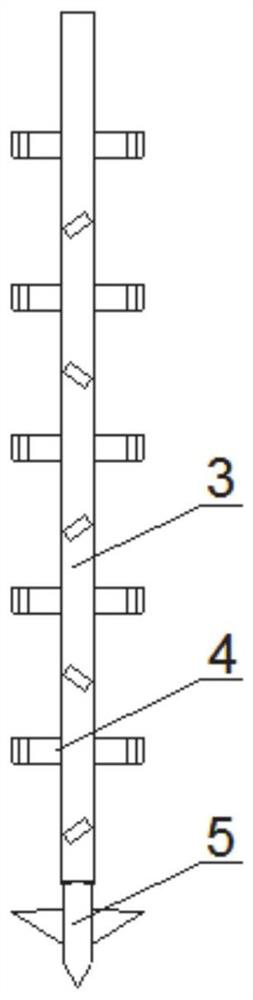

[0031] Such as Figure 1-Figure 2 As shown, the embodiment of the present invention provides a special drilling rod for cement-soil hard core composite pile combination. Three rotary knives are included in the knife assembly 4, and these three rotary knives are distributed in a circle, and these three rotary knives are on a horizontal plane, that is, each group of rotary cutters is distributed on the rod body in layers, wherein Layer spacing is 0.3m ~ 0.7m.

[0032] The bottom of described rod body 3 is connected with drill bit 5, and described drill rod is hollow, is provided with several liquid outlets on described drill bit, and described liquid outlet is connected with the central hole of drill rod, can realize like this While drilling, inject cement slurry into the borehole.

[0033] The drill bit 5 in the present embodiment is screwed together, so that it is convenient to replace a new drill bit when something goes wrong with the drill bit.

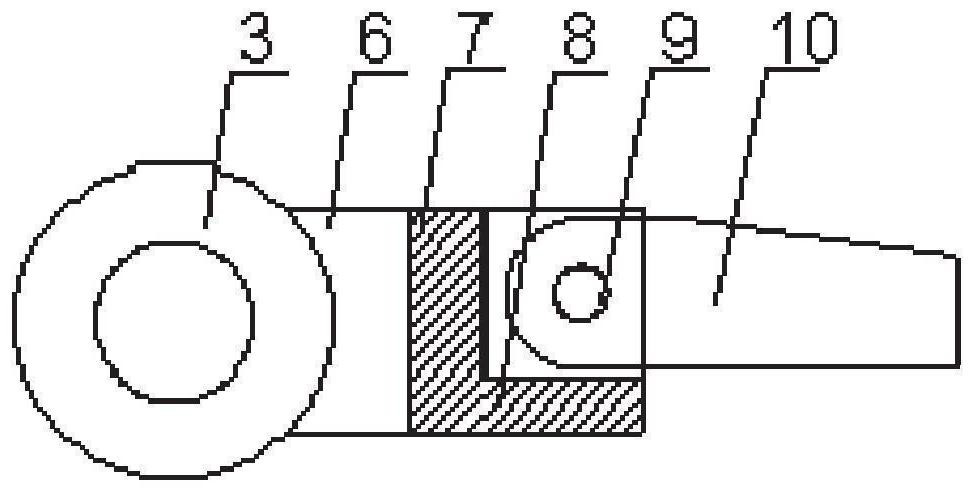

[0034] see image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com