Raised type coal particle environment-friendly drying equipment

A technology of drying equipment and particles, applied in non-progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems of coal fragmentation, limited height, and small turning range, and achieve fast heat absorption and heat conduction. , not easy to deform, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

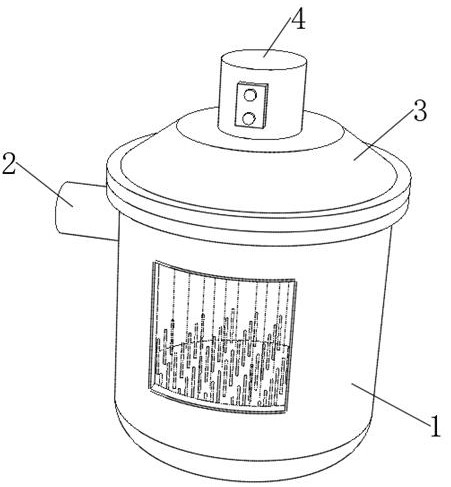

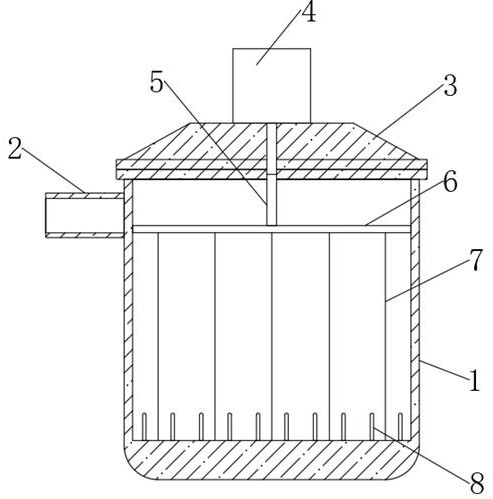

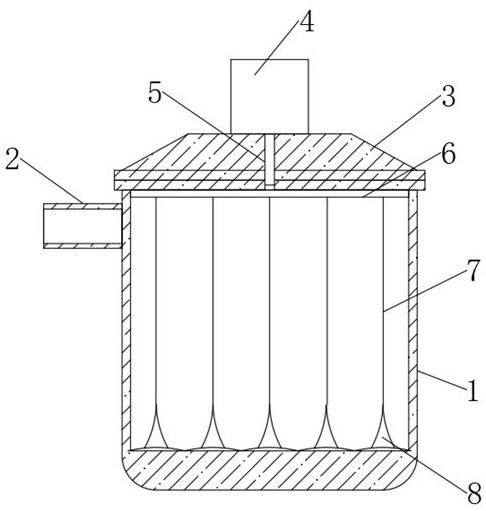

[0046] see Figure 1-4 , a raised type coal particle environmental protection drying equipment, including a drying cylinder 1, a hot air pipe 2 is installed on the side wall of the drying cylinder 1, a cover body 3 is installed on the upper end of the drying cylinder 1, a power supply box 4 is installed on the upper end of the cover body 3, and the power supply The lower end of the box 4 is electrically connected to an electric push rod 5, and the lower end of the electric push rod 5 is fixedly connected to a lifting plate 6, and the inner bottom of the drying cylinder 1 is fixedly connected to a plurality of evenly distributed drying plates 8, on which coal is laid. For particles, a linkage rod 7 is fixedly connected between the drying plate 8 and the lifting plate 6. The drying plate 8 includes a shaped plate body 81, a raised film 82 and a plurality of stretched films 83, and the raised film 82 is fixedly connected with the linkage rod 7. There is a main hole in the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com