Calibration device and method for a semiconductor test system

A technology for testing systems and calibration devices, applied to measuring devices, measuring electrical variables, instruments, etc., can solve the problems of slow system software upgrade iterations, time-consuming, and inconvenient maintenance and upgrades, and achieve fast testing and maintenance Convenience and the effect of reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

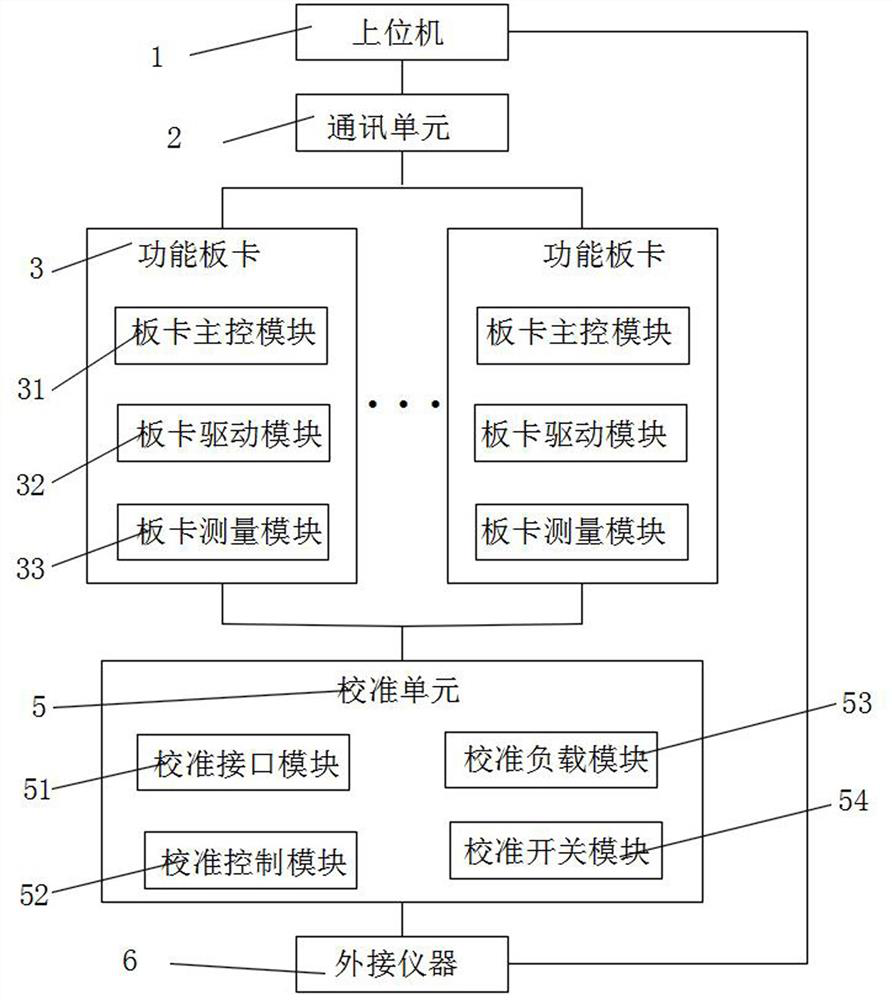

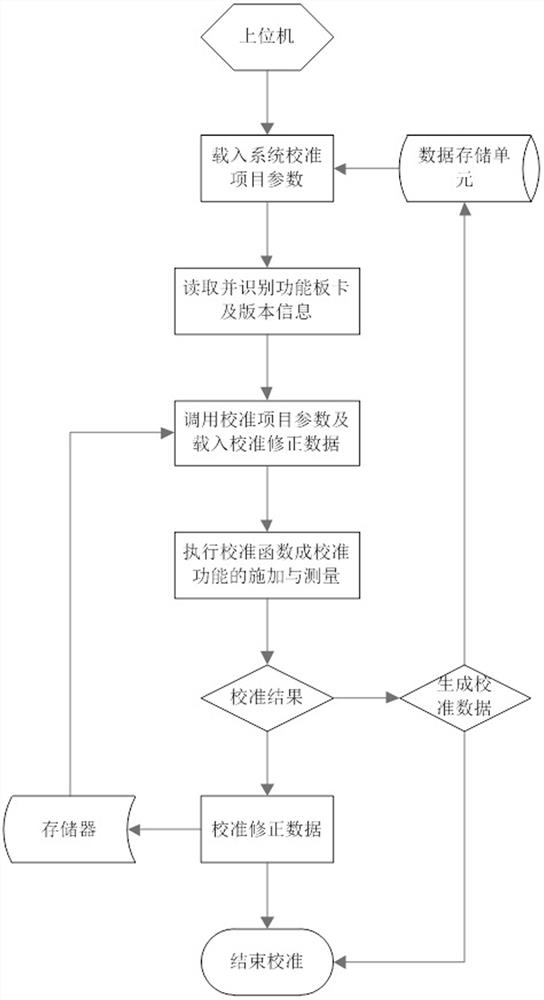

[0042] Such as Figure 1-4 As shown, the user uses the present invention to calibrate the voltage drive function of the functional board 3. First, the system software is started and the system starts to initialize the settings, load the calibration database file to read the preset value of the variable parameter of the calibration item, and then read the function through the function The board and version ID are loaded into the calibration correction data at the same time; next, the software completes the setting of the calibration interface module 51, the calibration switch module 54 and the calibration load module 53 of the calibration unit 5, and then the board main control of the function board 3 The module 31 controls the board driver module 32 to apply voltage, and then controls the external instrument 6 to complete the measurement of the voltage value. At the same time, the host computer 1 analyzes and judges the read measurement data. If the judged calibration result is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com