Packaging tool and packaging process for fuze product

A technology of packaging technology and tooling, which is applied in the direction of sealed casings, electrical components, electrical equipment casings/cabinets/drawers, etc., can solve problems such as unsafe, cumbersome, and affecting product performance, achieve safety performance guarantee, enhance plugging effect, The effect of eliminating the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described below, but the scope of claims is not limited to the above.

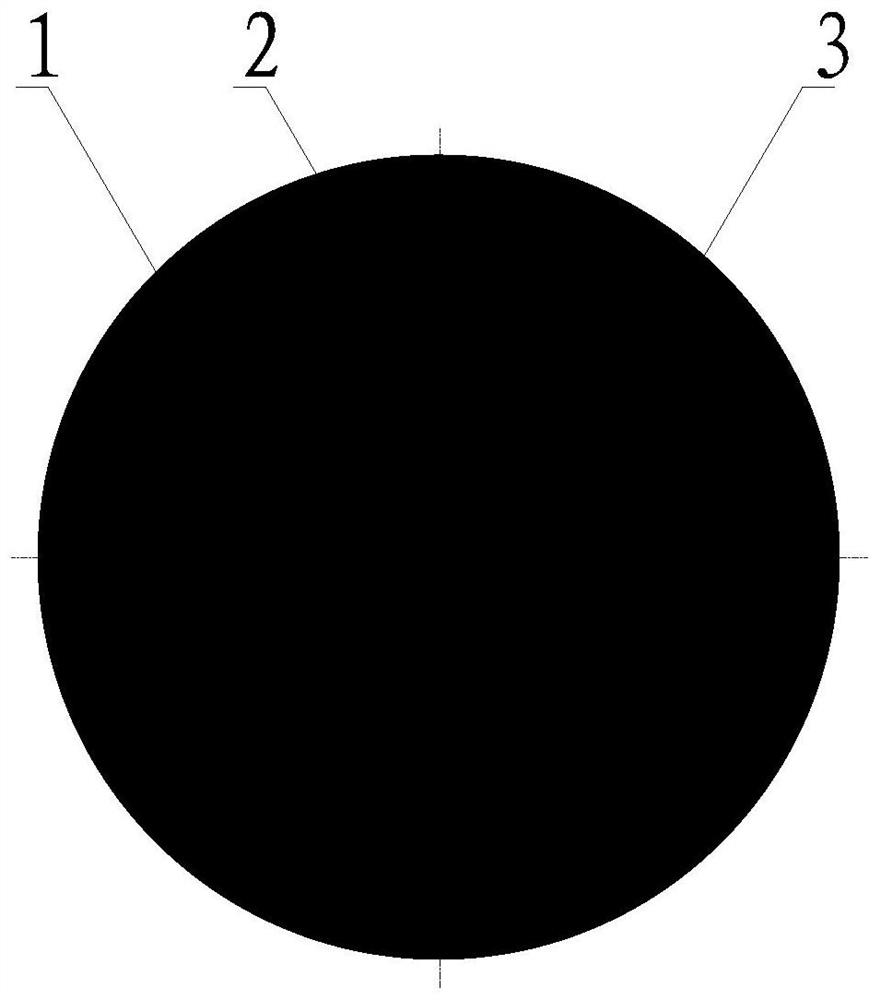

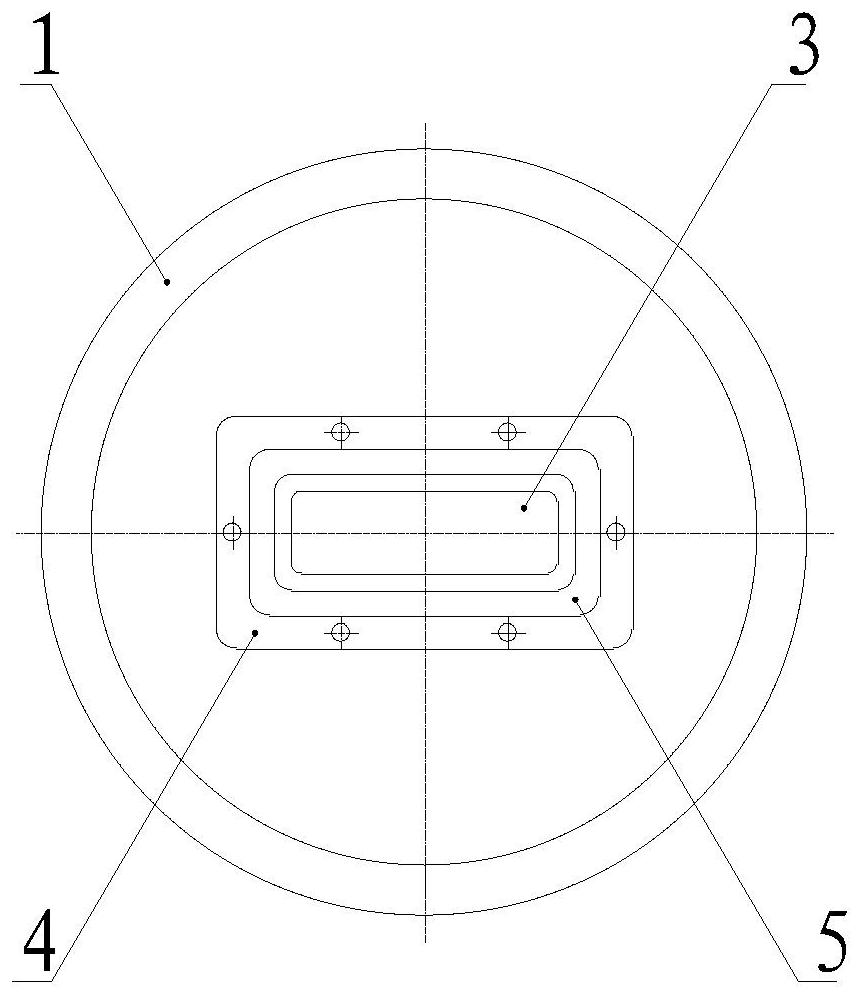

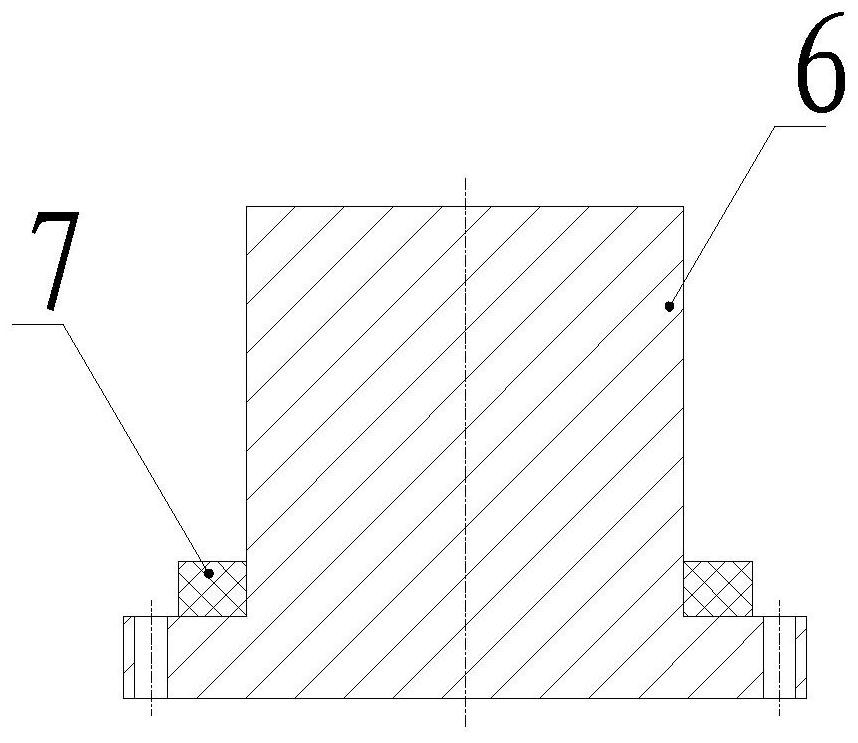

[0029] like figure 1 , figure 2 The modified product shown is composed of the casing 1, the circuit board 2, and the circuit board 2 is fastened to the casing 1 by the screw, in order to prevent the circuit board and the device damage or connection failure due to the impact, the circuit board is required. Perform a whole package. The cartridge 1, the intermediate portion of the circuit board 2 has a through chamber 3, and the casing 1 has a recess platform 4 and a ring groove 5 for encapsulating the electronic module. According to the currently conventional overall package method, the encapsulating rubber will flow into the cavity 3, the recess platform 4, the annular groove 5, and the reverse surface of the screw hole, which will affect the assembly and product performance of the product, and increase the elimination of extensive plastic The diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com