Solar photovoltaic panel surface cleaning system and cleaning method

A photovoltaic panel surface and cleaning system technology, applied in cleaning methods and appliances, cleaning methods using gas flow, photovoltaic power generation, etc., can solve the problems of time-consuming and labor-intensive manual cleaning, low cleaning efficiency, and high labor costs, and achieve Cleaning efficiency is efficient and fast, reducing cleaning costs and reducing load weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

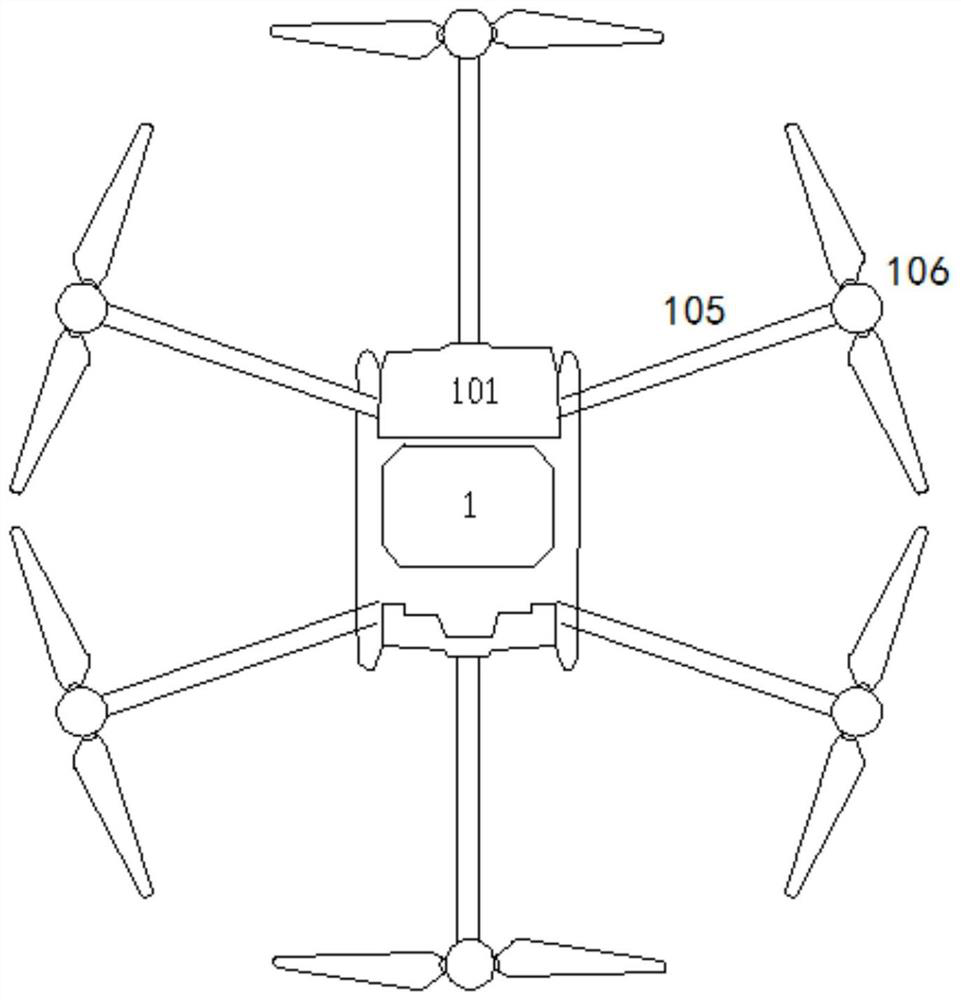

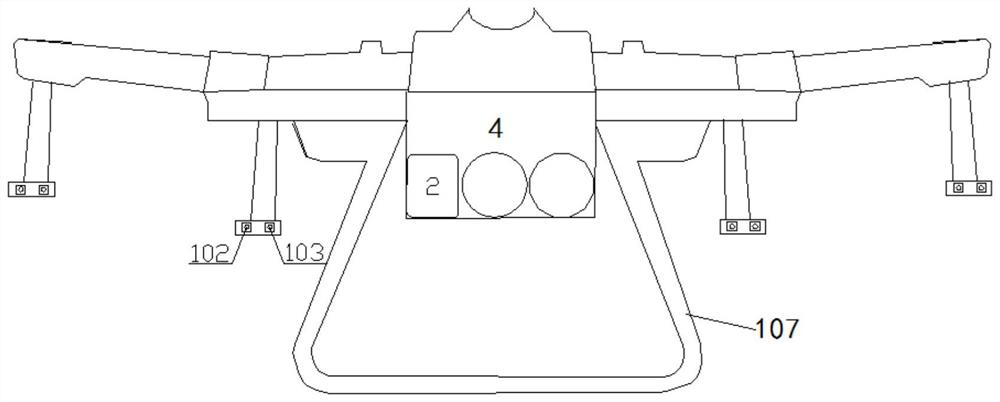

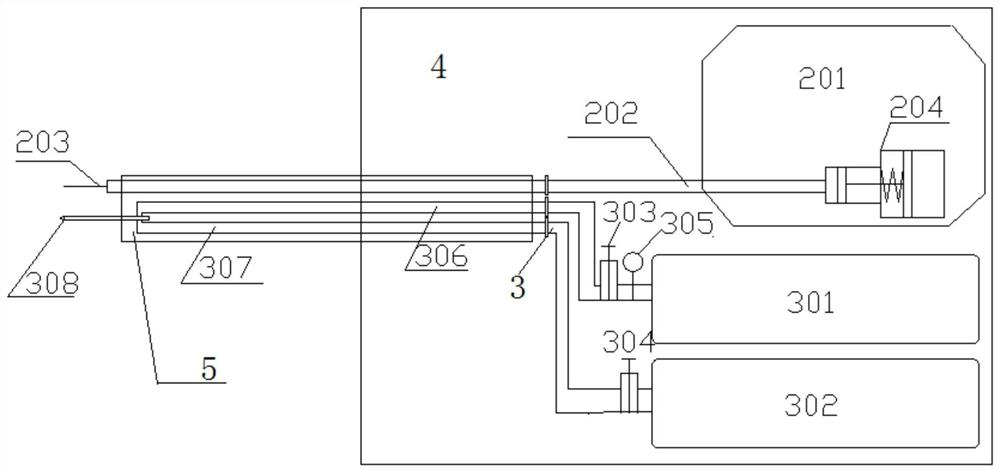

[0058] The drone inspects the photovoltaic panels, determines the specific location information of the stains on the photovoltaic panels through the infrared camera 102 and the stain positioning system 101, and then controls the drone to hover within 1 meter near the spot of the stains, and aligns the nozzle 203 with the stains on the photovoltaic panels , adjust the diaphragm pump 204 flow rate to 2L / min, the working time is 5 seconds, start the diaphragm pump 204, so that the cleaning liquid is sprayed from the nozzle 203; after the diaphragm pump 204 stops working for 5 seconds, first open the solenoid valve 303 to adjust the carbon fiber nitrogen cylinder The outlet pressure of the decompression valve 305 of 301 is 0.3MPa, so that nitrogen is ejected from the nozzle 308 to clean the impurity gas in the pipeline; after 2 seconds, the second solenoid valve 304 is opened to output liquid carbon dioxide; carbon dioxide is formed at the nozzle 308 snow, and spray carbon dioxide ...

Embodiment 2

[0060] The drone inspects the photovoltaic panels, determines the specific location information of the stains on the photovoltaic panels through the infrared camera 102 and the stain positioning system 101, and then controls the drone to hover within 1 meter near the spot of the stains, and aligns the nozzle 203 with the stains on the photovoltaic panels , adjust the diaphragm pump 204 flow rate to 3L / min, the working time is 5 seconds, start the diaphragm pump 204, so that the cleaning liquid is sprayed from the nozzle 203; after the diaphragm pump 204 stops working for 5 seconds, first open the solenoid valve 303 to adjust the carbon fiber nitrogen cylinder The outlet pressure of the pressure reducing valve 305 of 301 is 0.4MPa so that nitrogen is ejected from the nozzle 308 to clean the impurity gas in the pipeline; after 2 seconds, the solenoid valve 304 is opened to output the liquid carbon dioxide; carbon dioxide snow is formed at the nozzle 308, and Spray carbon dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com