A kind of mixed forming method of conical cylindrical part with straight cylinder and flaring

A technology of conical cylinder and straight cylinder, which is applied in the extrusion manufacturing of conical cylinder parts, flaring mixed forming, and conical cylinder parts with straight cylinder necking field, which can solve the problems of low material utilization rate, poor forging stability and finished product margin Large and other problems, to achieve the effect of simple method, good dimensional accuracy, and reduce the growth of metal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

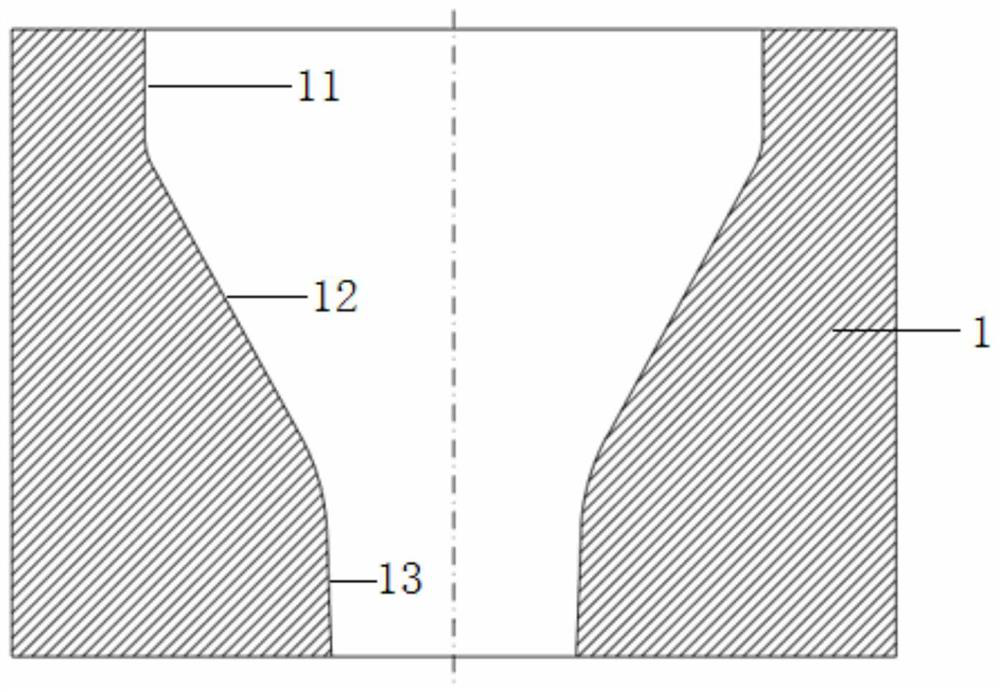

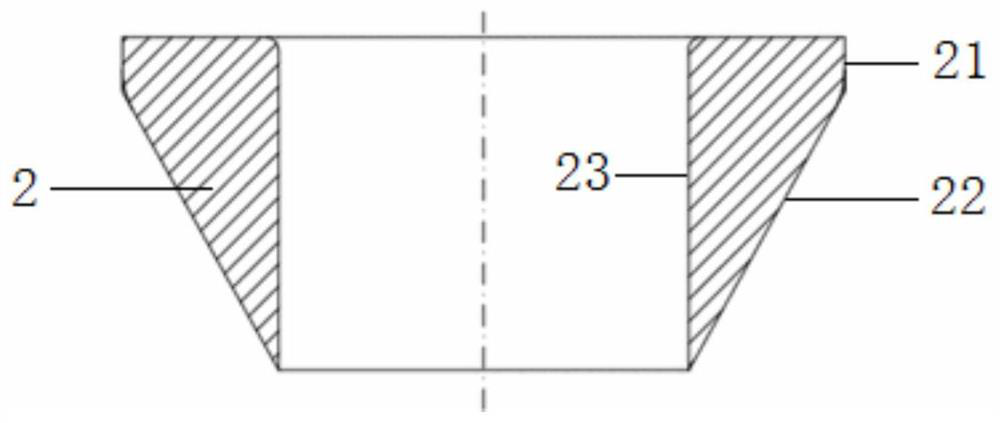

[0036] like Figure 1-Figure 6 As shown, the present embodiment has the following method for mixing the constriction and flaring of the straight-tube conical cylindrical part:

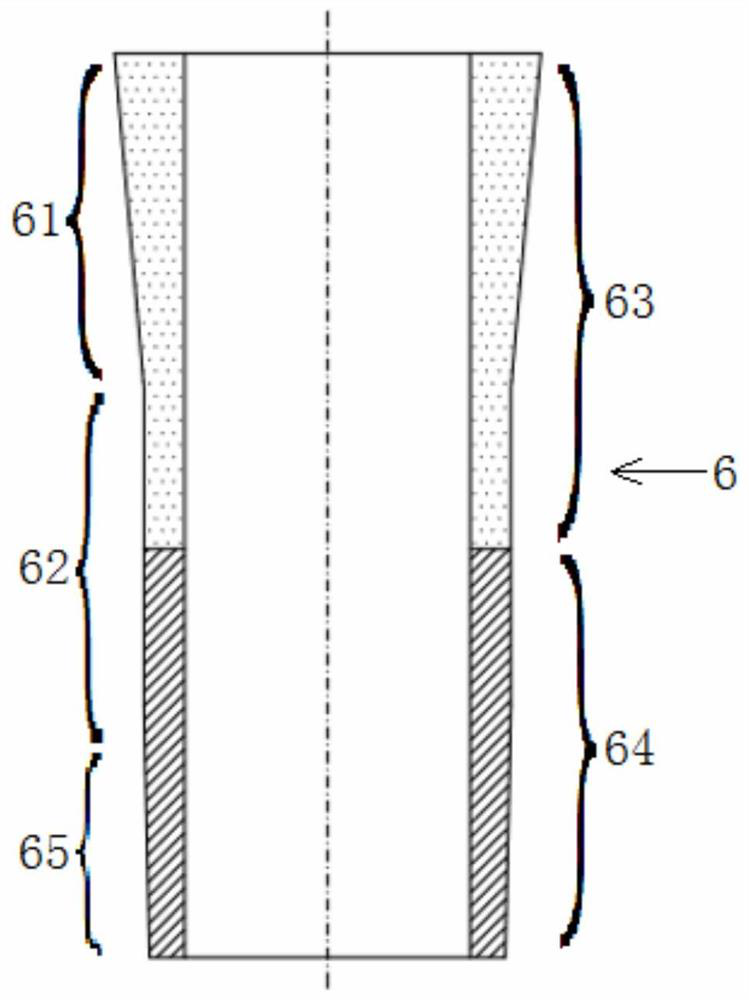

[0037] Step 1: As figure 1 As shown, a steel pipe with a wall thickness of 180 mm and an inner diameter of 730 mm is machined and cut into a frustum-shaped and cylindrical integrated tube blank 6 of a desired shape.

[0038] Among them, the truncated and cylindrical integrated tube blank 6 is a first truncated truncated tube blank 61, a cylindrical tube blank 62, and a second truncated truncated tube blank 65 that are coaxially integrated up and down. The inner diameter of the truncated and cylindrical integrated tube blank 6 They are equal to 730mm. The outer diameter of the first circular truncated tube blank 61 is larger in the upper part and smaller in the lower part. The height of the tube blank 61 is 850mm; the outer diameter of the cylindrical tube blank 62 is the same as the outer diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com