Preparation method of cloth-pattern-imitated rock plate

A slate and cloth imitation technology, applied in the field of architectural ceramics, can solve the problems of not being able to meet the decorative properties, endangering human health, and being prone to mildew, avoiding local color difference, excellent anti-scratch performance, and good decorative effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problem solved by the present invention, the technical scheme adopted and the technical effect achieved clearer, the present invention will be further described below in conjunction with embodiment:

[0029] A method for preparing a textured rock slab, comprising the following steps:

[0030] S1. Apply top glaze to the green body and dry it;

[0031] S2. Use oily matte ink and ceramic inkjet ink to print patterns; wherein, oily matte ink is used to form concave-convex patterns; ceramic inkjet ink is used to print pattern colors;

[0032] S3. Apply velvet-like glaze, the glaze amount is 200g / m 2 ;

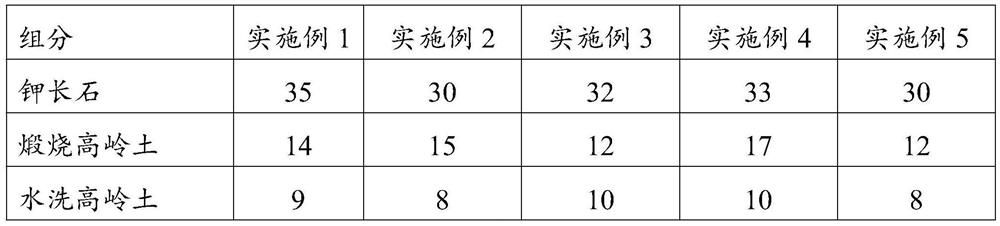

[0033] The velvet-like glaze comprises the following components in parts by weight:

[0034] components Example 1 Example 2 Example 3 Example 4 Example 5 Potassium feldspar 20 25 30 28 25 Calcined kaolin 35 32 25 28 30 Washed Kaolin 8 9 10 8 10 Aluminum oxide 5 7 8 6 5 Corundum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com