Sponge synthesized from bio-based isocyanate and mattress prepared from sponge

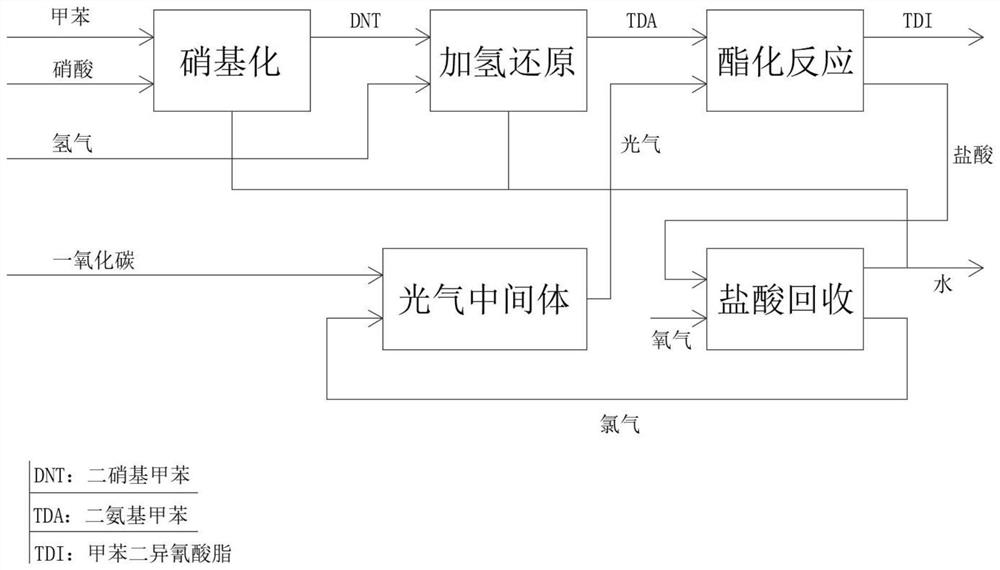

A toluene diisocyanate, bio-based technology, applied in the field of mattresses, can solve problems such as consumption of non-renewable petroleum, environmental pollution, adverse health reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

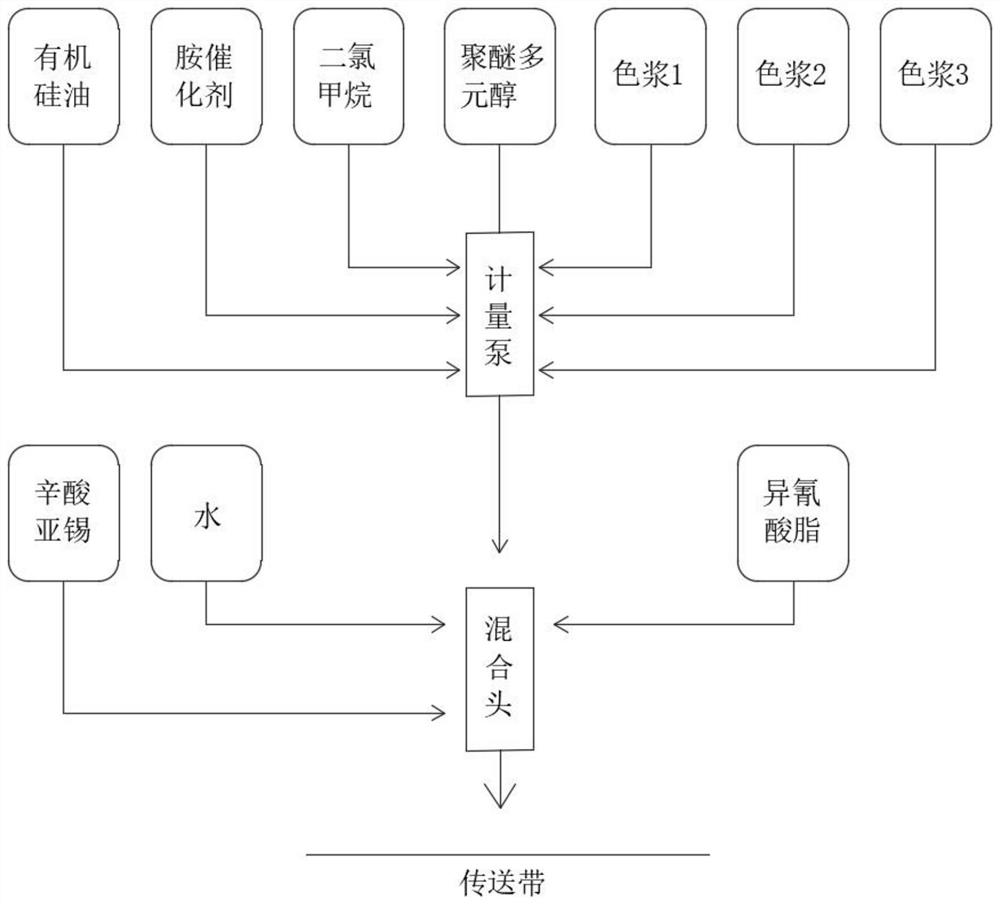

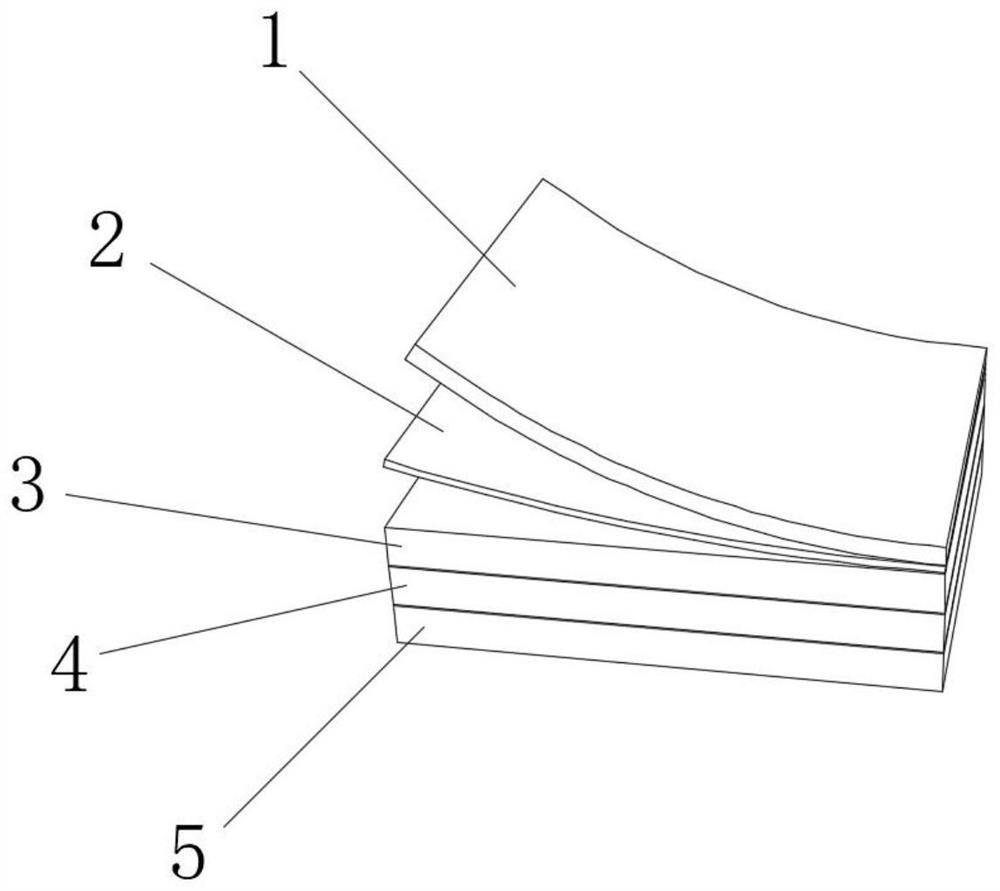

[0035] Such as Figure 4 As shown, formula 1-1 includes the following raw materials by weight: 100 parts of the first polyol, 2.8 parts of water, 0.8 parts of non-hydrolyzable silicone surfactant, 0.03 parts of the first amine catalyst, 0.15 parts of the second amine catalyst, 0.22 parts of stannous octoate, 39.89 parts of bio-based TDI.

[0036] Formula 1-2 includes the following raw materials by weight: 100 parts of the first polyol, 3.6 parts of water, 1 part of non-hydrolyzable silicone surfactant, 0.02 part of the first amine catalyst, 0.14 part of the second amine catalyst, stannous octoate 0.26 parts, bio-based TDI46.51 parts.

[0037] Formula 1-3 includes the following raw materials by weight: 100 parts of the first polyol, 4.7 parts of water, 11 parts of dichloromethane, 1.5 parts of non-hydrolyzable silicone surfactant, 0.1 part of the second amine catalyst, 0.39 parts of stannous octoate parts, bio-based TDI61.84 parts.

[0038] Such as Figure 5 As shown, formu...

Embodiment 2

[0049] Such as Figure 6 As shown, formula 3-1 includes the following raw materials in parts by weight: 30 parts of the fourth polyol, 70 parts of the fifth polyol, 3.6 parts of water, 1 part of non-hydrolyzable silicone surfactant, and 0.07 parts of the first amine catalyst , 0.1 part of the second amine catalyst, 0.03 part of stannous octoate, and 36.82 parts of bio-based TDI.

[0050] Formula 3-2 includes the following raw materials in parts by weight: 25 parts of the fourth polyol, 75 parts of the fifth polyol, 3.5 parts of water, 8 parts of methylene chloride, 1.2 parts of non-hydrolyzable silicone surfactant, the first amine 0.07 parts of the catalyst, 0.1 parts of the second amine catalyst, 0.03 parts of stannous octoate, and 36.52 parts of bio-based TDI.

[0051] Formula 3-5 includes the following raw materials by weight: 20 parts of the fourth polyol, 80 parts of the fifth polyol, 3.5 parts of water, 12 parts of dichloromethane, 1.4 parts of non-hydrolyzable silicone...

Embodiment 3

[0059] Such as Figure 7 As shown, formula 4-1 includes the following raw materials by weight: 80 parts of the sixth polyol, 20 parts of the fourth polyol, 0.3 parts of hydrolyzed silicone surfactant, 1.5 parts of water, 1 part of BDO, the first amine catalyst 0.13 parts, 0.2 parts of the second amine catalyst, 0.02 parts of stannous octoate, 43 parts of bio-based TDI.

[0060] Formula 4-2 includes the following raw materials in parts by weight: 90 parts of the sixth polyol, 10 parts of the seventh polyol, 0.3 parts of hydrolyzed silicone surfactant, 1.5 parts of water, 1 part of BDO, 0.13 parts of the first amine catalyst, 0.2 parts of the second amine catalyst, 0.02 parts of stannous octoate, and 41 parts of bio-based TDI.

[0061] Formula 4-3 includes the following raw materials in parts by weight: 100 parts of sixth polyol, 0.5 parts of hydrolyzed silicone surfactant, 1.9 parts of water, 1.2 parts of BDO, 0.12 parts of the first amine catalyst, and 0.2 parts of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com