Method for extracting and separating grease from seaweed

A technology of oil separation and extraction, which is applied in the direction of oil/fat production and fat generation, can solve the problems of high environmental pollution and low efficiency, and achieve the effect of high extraction rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

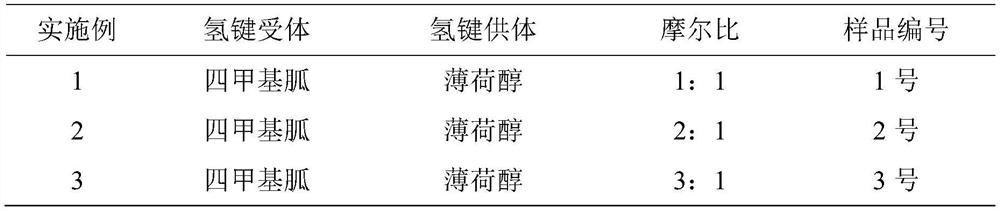

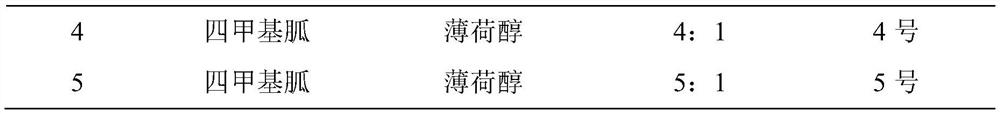

[0029] Different proportions of hydrogen bond acceptors and hydrogen bond acceptors were used to prepare deep eutectic solvents. The preparation method is as follows:

[0030] Using menthol as a hydrogen bond donor and tetramethylguanidine as a hydrogen bond acceptor, add them into a round-bottomed flask in a certain proportion for mixing, heat in a water bath to 60-80°C, and stir to react to obtain a deep eutectic solvent; wherein, The molar ratios of hydrogen bond acceptors and hydrogen bond donors are shown in Table 1:

[0031] Table 1 Molar ratios of hydrogen bond donors and hydrogen bond acceptors in deep eutectic solvents

[0032]

[0033]

Embodiment 6~10

[0035] The deep eutectic solvent samples made in Examples 1 to 5 were respectively used to extract oils and fats in seaweed, specifically including the following steps:

[0036] S1. Add seaweed, deep eutectic solvent, and ammonium sulfate aqueous solution into a test tube at a solid-to-liquid ratio of 1g:30mL for mixing, and then carry out an extraction reaction at 70°C for 70 minutes;

[0037] S2. After the extraction is completed, solid-liquid separation is performed to obtain a mixed solution, and carbon dioxide is introduced into the mixed solution for separation and recovery;

[0038] Wherein, the concentration of ammonium sulfate aqueous solution is 20wt%.

[0039] After the extraction, the aqueous phase, oil and deep eutectic solvent were separated, and the extraction rate of each sample to oil was tested, and the results are shown in Table 2.

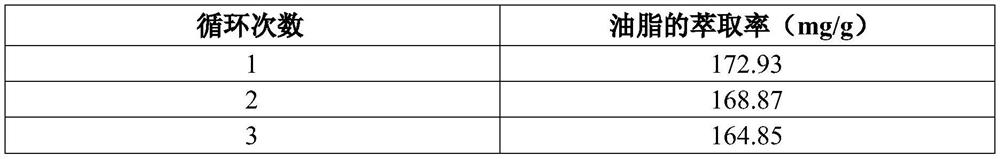

Embodiment 11

[0041] The extraction method of this example is the same as that of Example 6, except that tert-butanol is used instead of the deep eutectic solvent for extraction, and the extraction results are shown in Table 2.

[0042] Table 2 embodiment 6~11 to the extraction rate of oil in seaweed

[0043] Example type Oil extraction rate (mg / g) 6 Sample No. 1 153.18 7 No. 2 sample 155.22 8 Sample No. 3 160.09 9 No. 4 sample 156.85 10 Sample No. 5 154.44 11 tert-butanol 134.10

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com