Arc surface dust blocking tool and rotary target material thermal spraying device using the same

A dust-proof and curved surface technology, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of overheating at the end of the target, poor thermal conductivity, and reduced production efficiency, so as to reduce thermal stress, The effect of improving service life and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention has been further described in detail below in conjunction with specific embodiments.

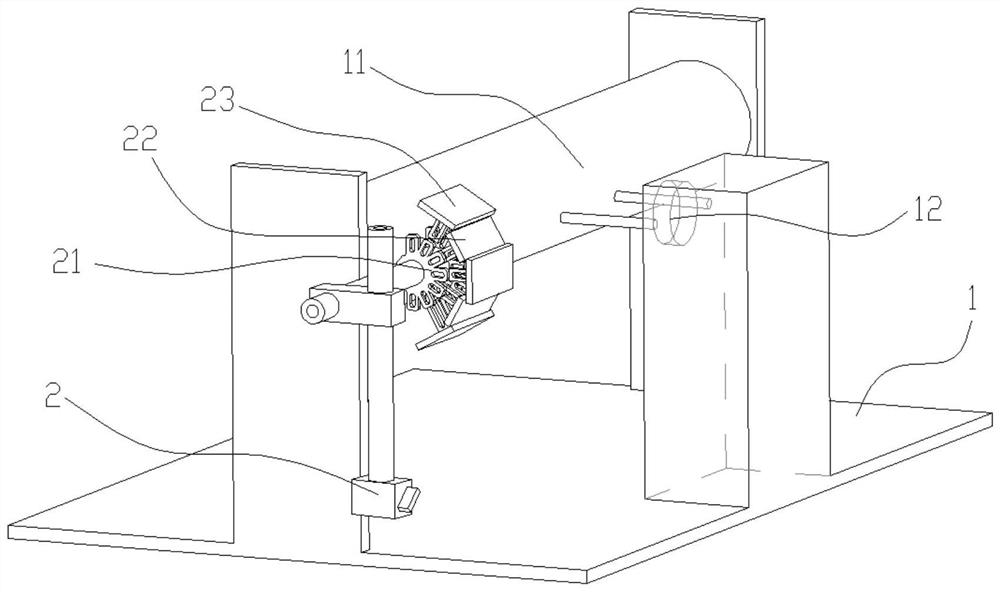

[0021] like figure 1 As shown, the rotating target thermal spray device 1 includes a target mounting position 11, provided in a spray gun (not shown) on the target mounting position side, and the air outlet 12 on the other side, further comprising a target mounting The arc surface of the exit portion 12 side ends 2, the inner surface of the curved shutter of the curved shutter 2 is positive on the target mounting position. The rotating target thermal spray device is used for processing ceramic targets.

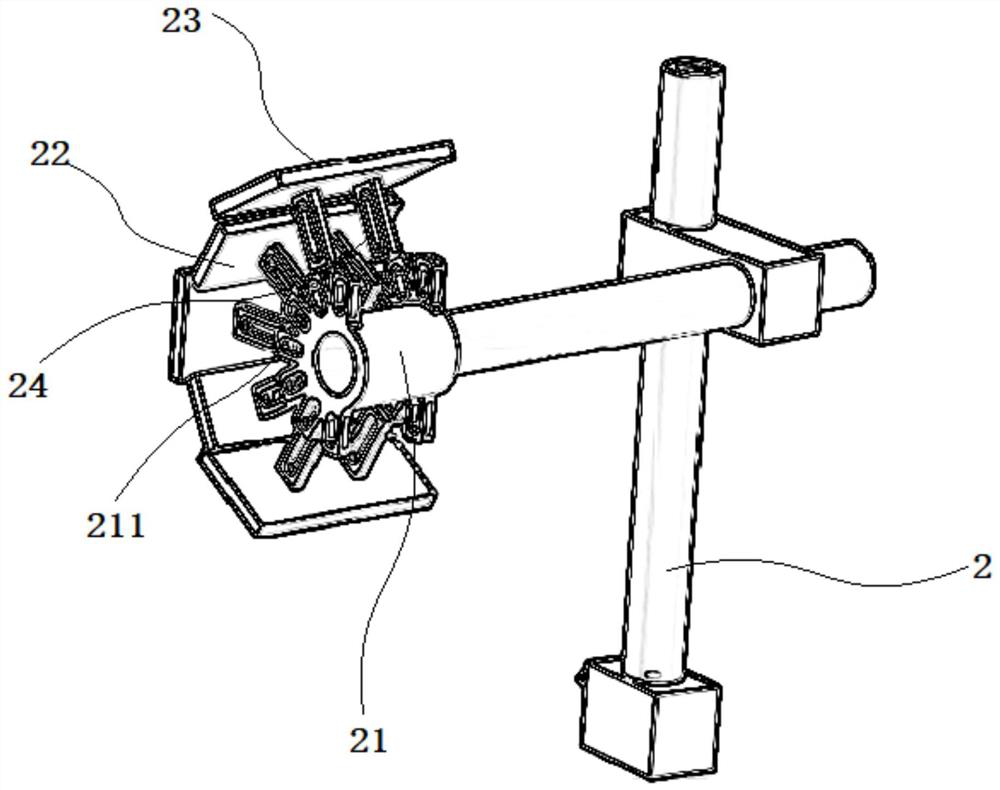

[0022] like figure 2 with image 3 As shown, the curved dust collecting 2 includes a support rod and a ring mount 21 and an arcuate baffle mounted on the end of the support rod. The support rod is laterally projecting the connecting rod, and the mounting seat 21 is sleeved in the end of the connecting rod around the center axis of the connecting rod. The mounting seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com