A kind of seamless composite fiber pipe manufacturing equipment and seamless composite fiber pipe

A composite fiber and manufacturing equipment technology, applied in textiles and papermaking, looms, circular looms, etc., can solve the problems of limited use range, the inability of mixed fiber reinforced materials to achieve mechanical properties, etc., and achieve high hardness and crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

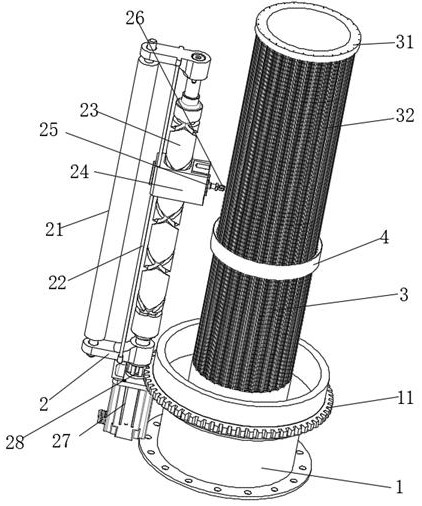

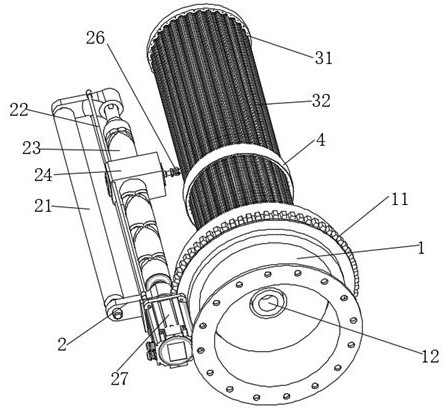

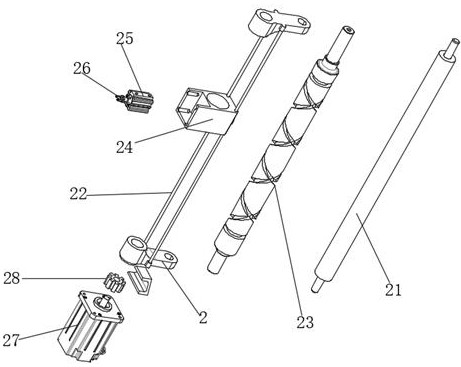

[0041] see Figure 1-4 And 7, a seamless composite fiber pipe manufacturing equipment and seamless composite fiber pipe, including a pipe sleeve 3 and a spiral braiding device, the bottom of the pipe sleeve 3 is provided with a base 1, and the spiral braiding device includes two symmetrically arranged supports 2, located at The bracket 2 at the bottom end is connected to the outer wall of the base 1 through a bearing structure. The rotation connection between the two brackets 2 is provided with a weft thread supply roller 21 and a reciprocating screw mandrel 23. The weft thread supply roller 21 and the reciprocating screw mandrel 23 are arranged in parallel. A servo motor 27 is fixed, the output end of the servo motor 27 is fixedly connected to the bottom end of the reciprocating screw rod 23, the output end of the servo motor 27 is fixed with a drive gear 28, and the outer wall of the base 1 is fixed with a gear ring 11 matching the drive gear 28 , the reciprocating screw rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com