Supporting steel pipe stand column and fire pool wall connecting structure and construction method

A technology for steel pipe columns and pool walls, which is used in water conservancy projects, underwater structures, infrastructure projects, etc., can solve the problems of the waterproof effect of post-casting belts and the inability to guarantee construction quality, and achieve good construction quality, enhanced connectivity and Integrity, ensuring the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

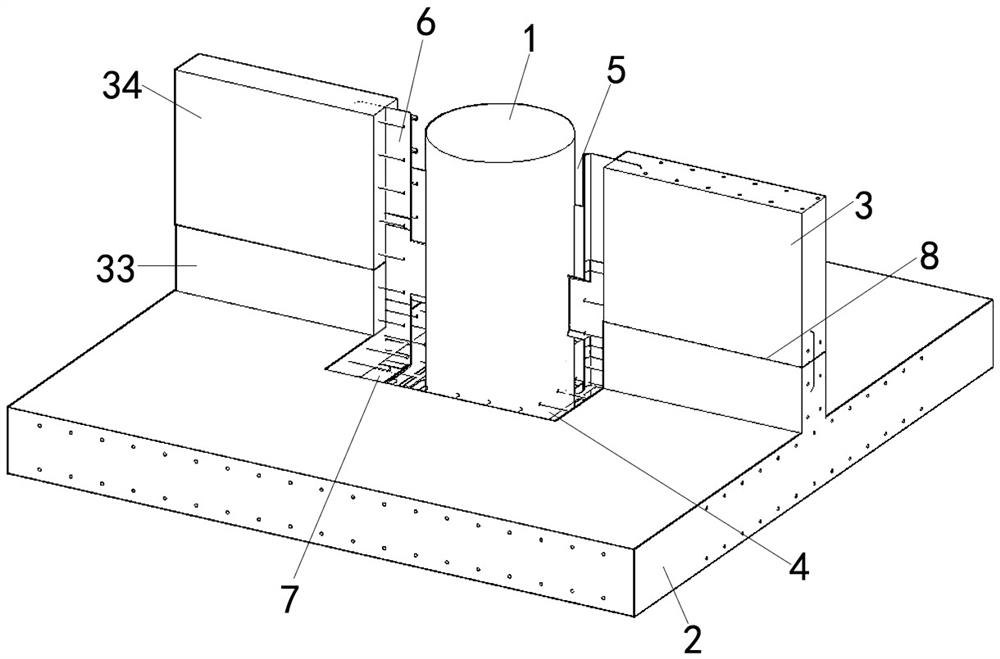

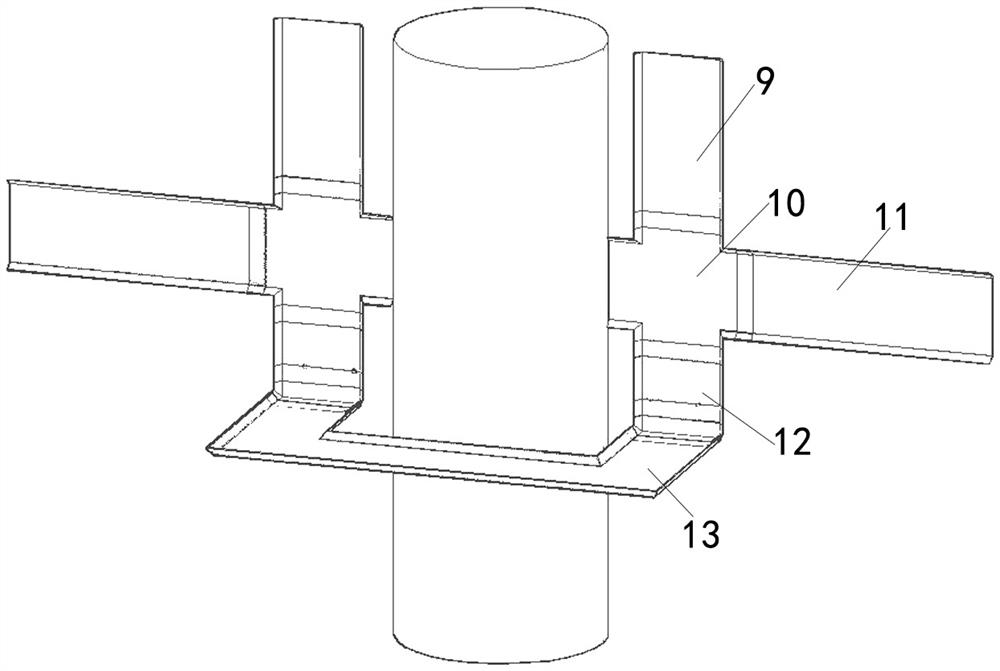

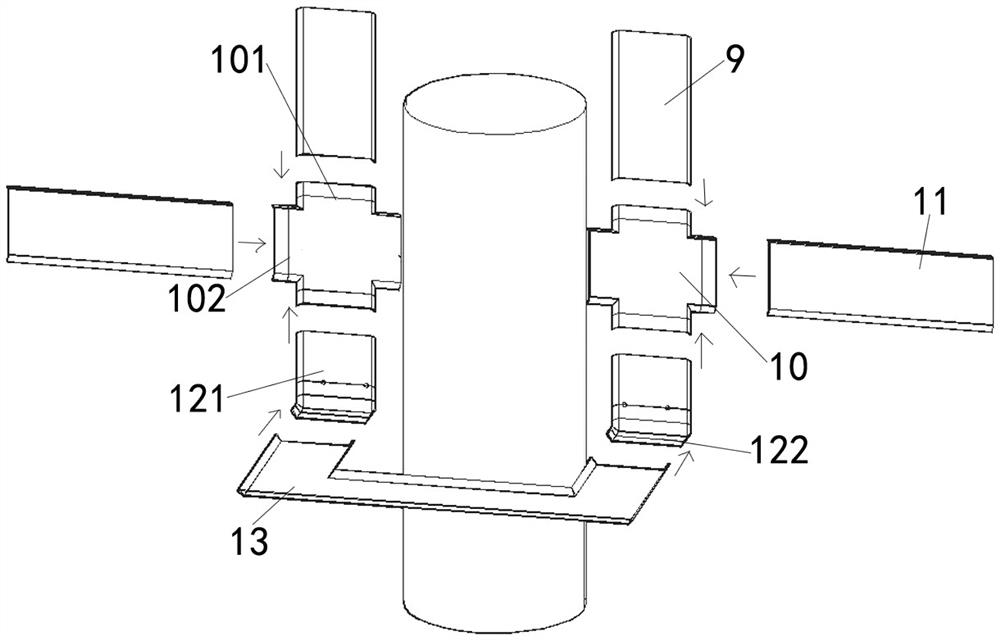

[0055] Examples see Figure 1-5 As shown in the figure, a structure for connecting the supporting steel pipe column and the fire pool wall includes the foundation pit supporting steel pipe column 1, the horizontal bottom plate 2, the fire pool wall plate 3 and the combined water-stop steel plate.

[0056] In this embodiment, the steel pipe column for foundation pit support is a steel pipe reinforced concrete column with a circular cross section and a diameter of 620mm. The thickness of the fire pool wall panel 3 is 200mm. The thickness of the bottom plate is 300mm. In this embodiment, the steel cross-sectional dimensions of the combined waterproof steel plate parts are all the same, 300mm×3mm.

[0057] The bottom of the foundation pit supporting steel pipe column 1 stands on the ground of the foundation pit, and the fire-fighting pool wall plate 3 is perpendicular to the bottom plate 2 and is fixedly connected with it. The post-cast belt that passes through the top of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap