Testing equipment and method for testing single board

A technology for testing equipment and single boards, which is applied in the field of testing and can solve problems such as the inability of single boards to realize functions and the low pass-through rate of production equipment modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

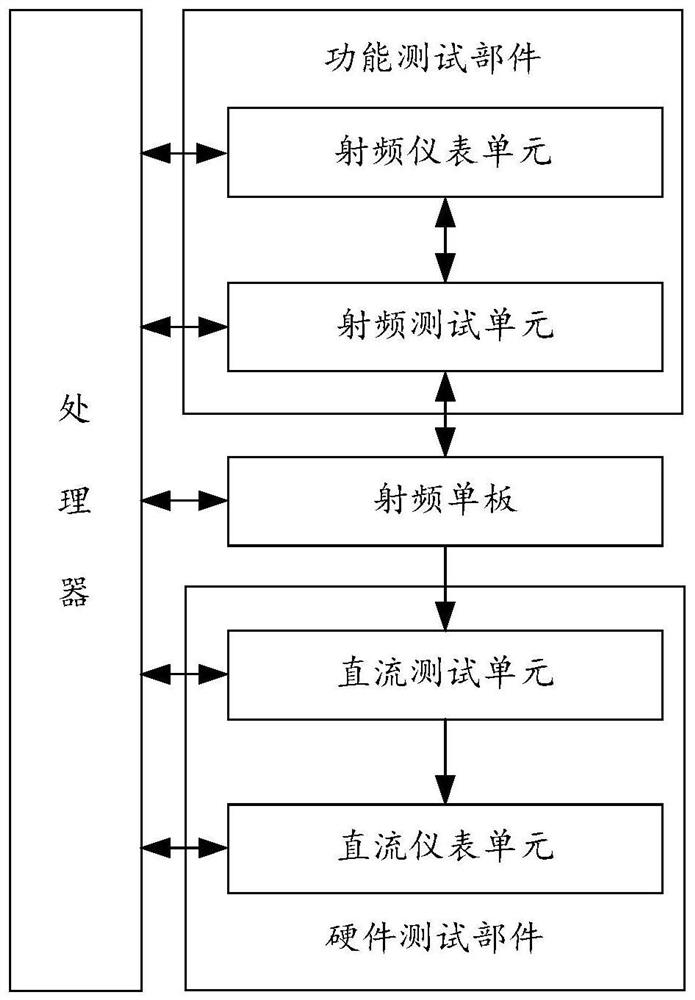

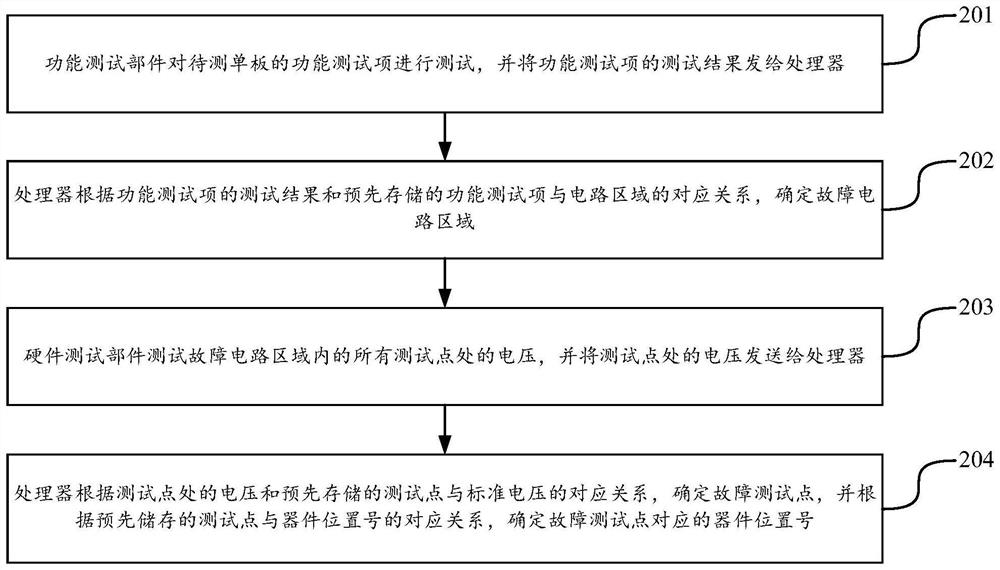

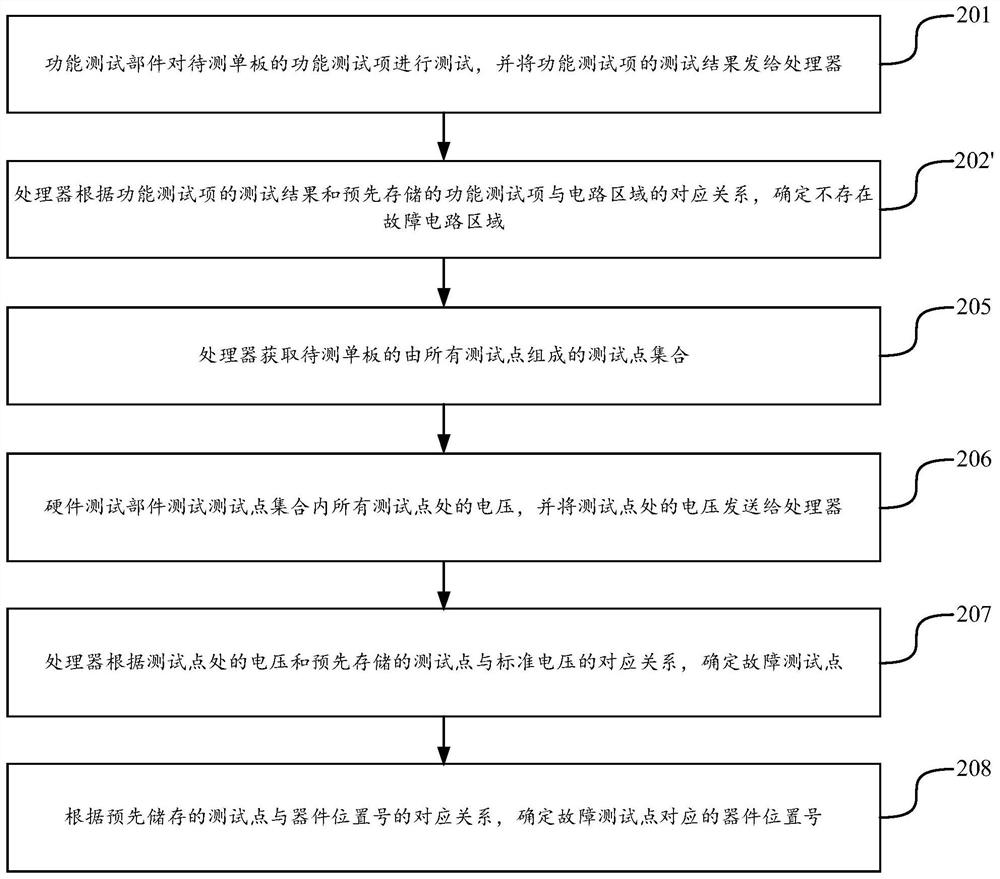

[0059] The embodiment of the present application relates to a test device for testing a single board, wherein the single board may be a main control board, an interface board, or a service board in a communication device, for example, it may be a radio frequency unit in a radio frequency module of a communication device plate.

[0060] In some applications, during the processing of communication equipment, various components are usually installed on the printed circuit board (PCB) through mounting technology, such as installing capacitors, resistors, diodes and triodes, etc., to complete various After the components are mounted, a printed circuit board assembly (PCBA) can be obtained. Then, the test equipment described in this embodiment may be used to test the assembled printed circuit board (single board for short), where the test may include function test and hardware test. After passing the test, the printed circuit board can be assembled together with other components or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com