A kind of method for preparing mnzn ferrite u-shaped magnetic core

A ferrite, U-shaped technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of high cost and complex process, and achieve the effect of improving performance, improving the uniformity of heating, and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] S1, under an air atmosphere (usually an atmospheric environment), 7 parts by weight of Fe2O3, 2 parts of Mn3O4 and 1 part of ZnO and containing trace impurity element oxides are made into spherical particles with a diameter of 50 μm to 300 μm by ball milling and Mix evenly to obtain spherical particle raw materials. In this process, it is necessary to mix the three kinds of spherical particles uniformly to the greatest extent, increase the contact area between each other, and promote the full progress of the subsequent reaction; at the same time, it is necessary to allow the air to contact the surface of the spherical particles evenly to avoid air in the spherical particles. The local concentration on the particles destroys the equilibrium atmosphere in the subsequent reaction process.

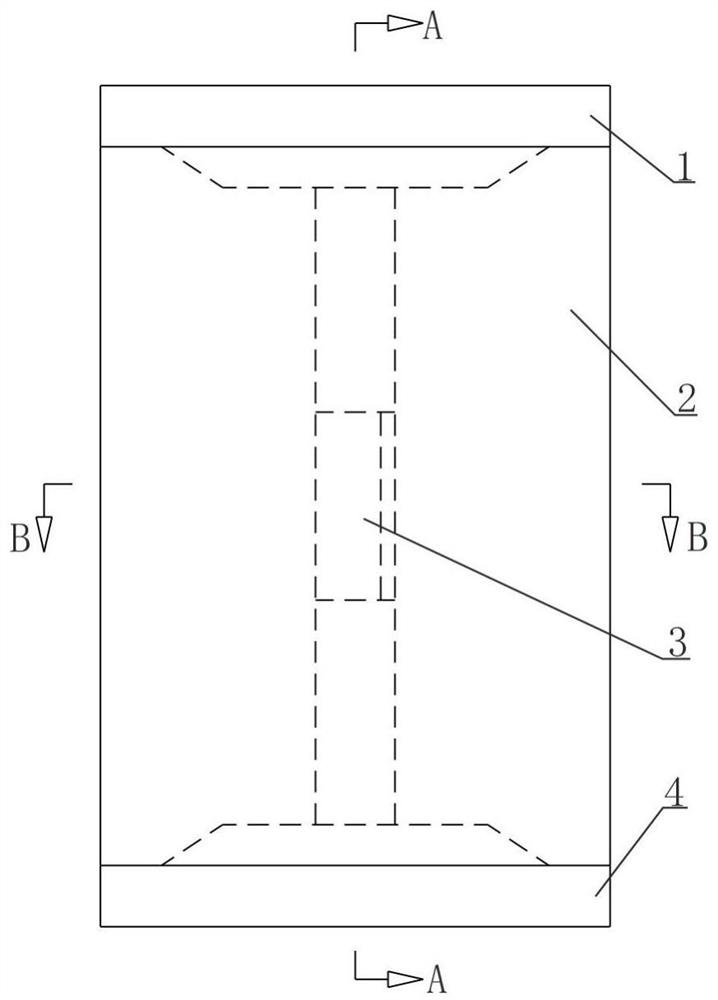

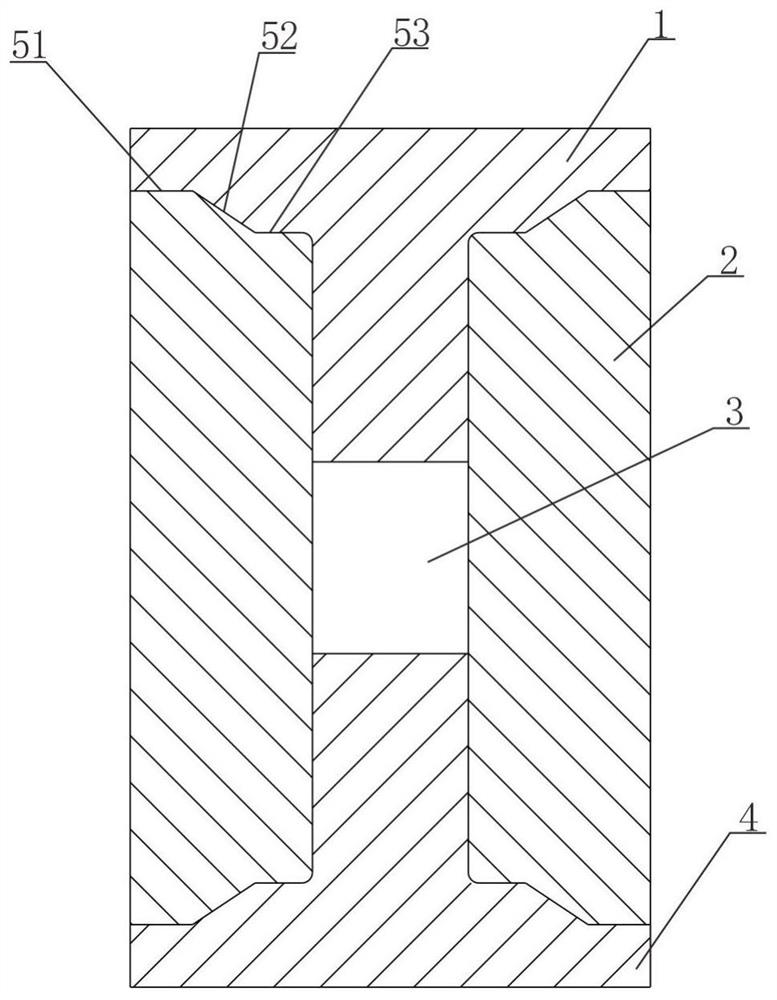

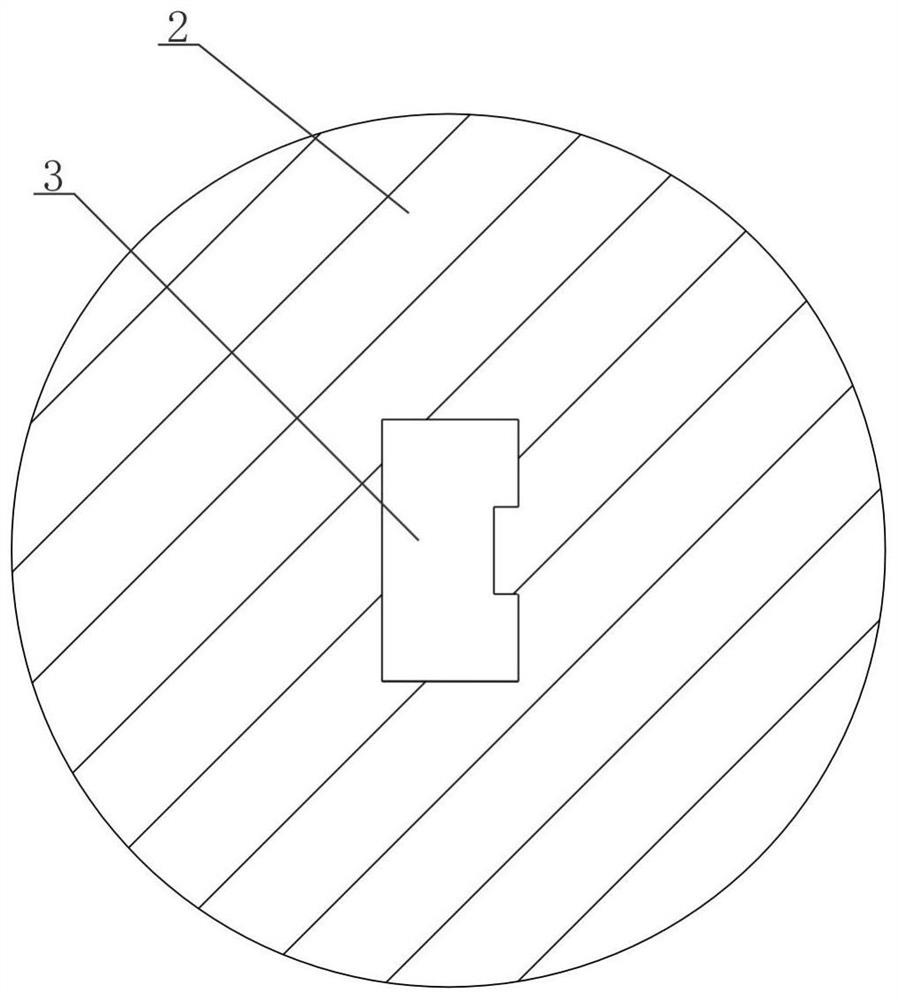

[0052] S2, according to the volume and theoretical density of a single U-shaped magnetic core to be prepared (usually 5.08g / cm 3 ) to calculate the quality of the required spherical pa...

Embodiment 2

[0077] S1, under an air atmosphere (usually an atmospheric environment), 8 parts by weight of Fe2O3, 1.5 parts of Mn3O4 and 0.8 parts of ZnO and containing trace impurity element oxides are made into spherical particles with a diameter of 50 μm to 300 μm by ball milling and Mix evenly to obtain spherical particle raw materials, such as Figure 4 Shown is the SEM morphology characterization photo of the spherical particle raw material.

[0078]S2, according to the volume and theoretical density of a single U-shaped magnetic core to be prepared (usually 5.08g / cm 3 ) to calculate the quality of the required spherical particle raw material, and accurately weigh the spherical particle raw material of this quality and fill it in the cavity 3 of the graphite mould.

[0079] S3, the cavity is sealed after the spherical particle raw material is filled, and the proportion of oxygen partial pressure in cavity 3 is adjusted to 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com