Enteral nutrition composition as well as preparation method and application thereof

A technology of enteral nutrition and composition, which is applied in the field of pharmaceutical preparations, and can solve problems such as the amount of vitamins and/or minerals not meeting the specified requirements, difficulties in transportation and storage, precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

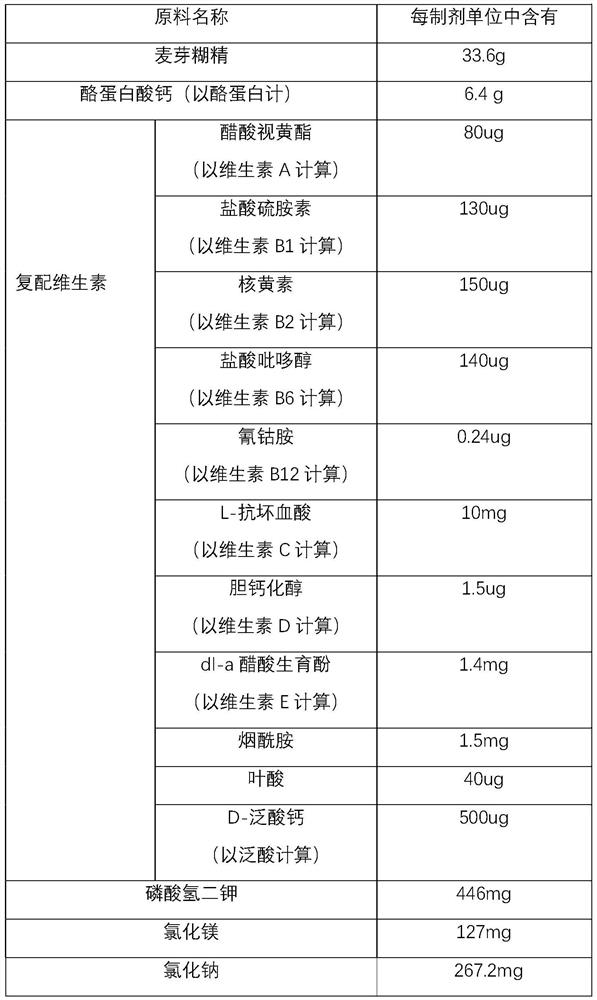

[0037] Example 1: Enteral nutritional composition

[0038] The product composition is shown in Table 1.

[0039] Table 1:

[0040]

[0041] Preparation: Weigh the raw material powders according to the dosage and mix them to obtain 1 preparation unit of the enteral nutrition composition, which can be packed in bags, and 1 pack or 1 bag is 1 preparation unit. Just before use, add purified water to dissolve to make a 200ml suspension, as an enteral nutrient. The prepared suspension can be heated or boiled as required, and the solution is stable without flocculation or precipitation. During preparation, for example, 1,000 preparation units can be fed, mixed thoroughly and subpackaged into 1,000 preparation units.

Embodiment 2

[0042] Example 2: Enteral nutritional composition

[0043] The composition of the product is shown in Table 2.

[0044] Table 2:

[0045]

[0046] Preparation: Weigh each raw material powder according to the dosage (wherein the magnesium chloride is magnesium chloride hexahydrate), and mix them to obtain 1 preparation unit of the enteral nutrition composition. Just before use, add purified water to dissolve to make a 200ml suspension, as an enteral nutrient. The prepared suspension can be heated or boiled as required, and the solution is stable without flocculation or precipitation.

Embodiment 3

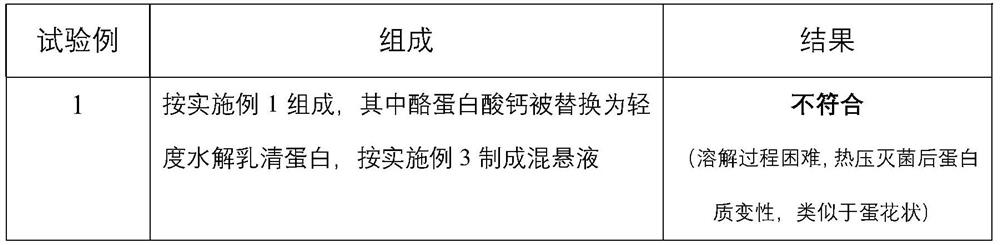

[0047] Example 3: Enteral nutrition suspension

[0048] According to the composition in Table 1 of Example 1, take the required amount of each raw material, add purified water, dissolve and prepare a suspension of 200 ml, and make an enteral nutrition suspension after high-temperature autoclaving.

[0049] making process:

[0050] Weigh the specified amount of calcium caseinate and maltodextrin, add purified water to prepare a solution, add the specified amount of vitamin fine powder, stir for 1 hour, then add dipotassium hydrogen phosphate, magnesium chloride, and sodium chloride in turn, stir, and dissolve Afterwards, it becomes a uniformly dispersed milky white liquid, which is filtered through a sieve of 300-400 mesh, and then sterilized by autoclaving at 110 degrees.

[0051] Perform product osmolarity, pH and energy density checks. The result is: the osmotic pressure of the product is 300mOsmol / L (the osmotic pressure is measured with reference to the detection method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com