Long bar online automatic discharging device and method used for bearing production

A bearing production and automatic blanking technology, which is applied in the direction of operating devices, forging/pressing/hammer devices, engine components, etc., can solve the problems of large loss of raw materials, high blanking costs, inaccurate temperature control of forgings, etc., to ensure operation The effect of safety, ensuring the quality of forgings and saving material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

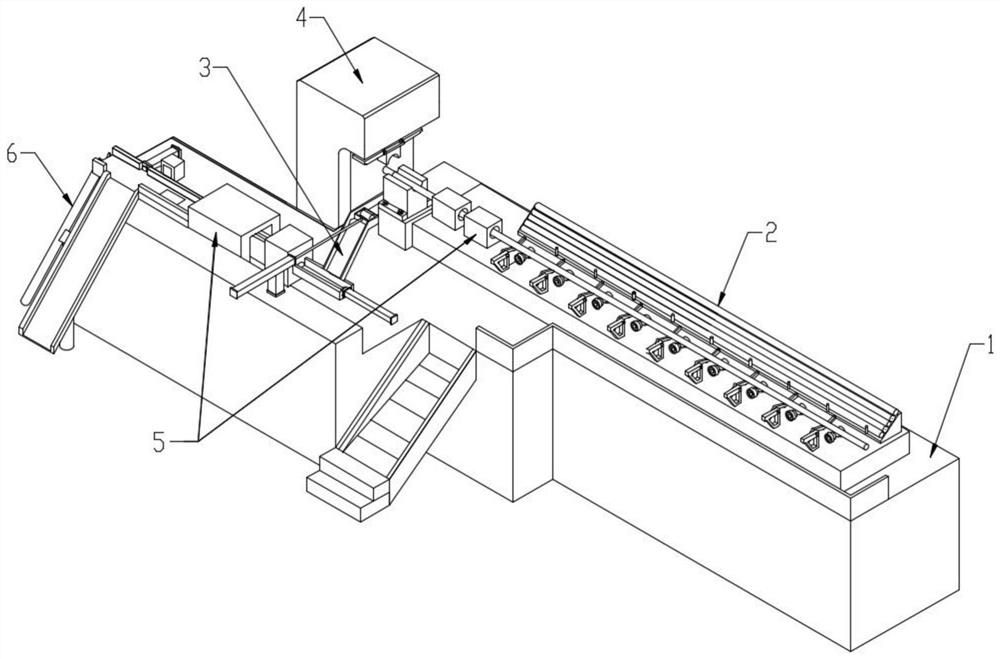

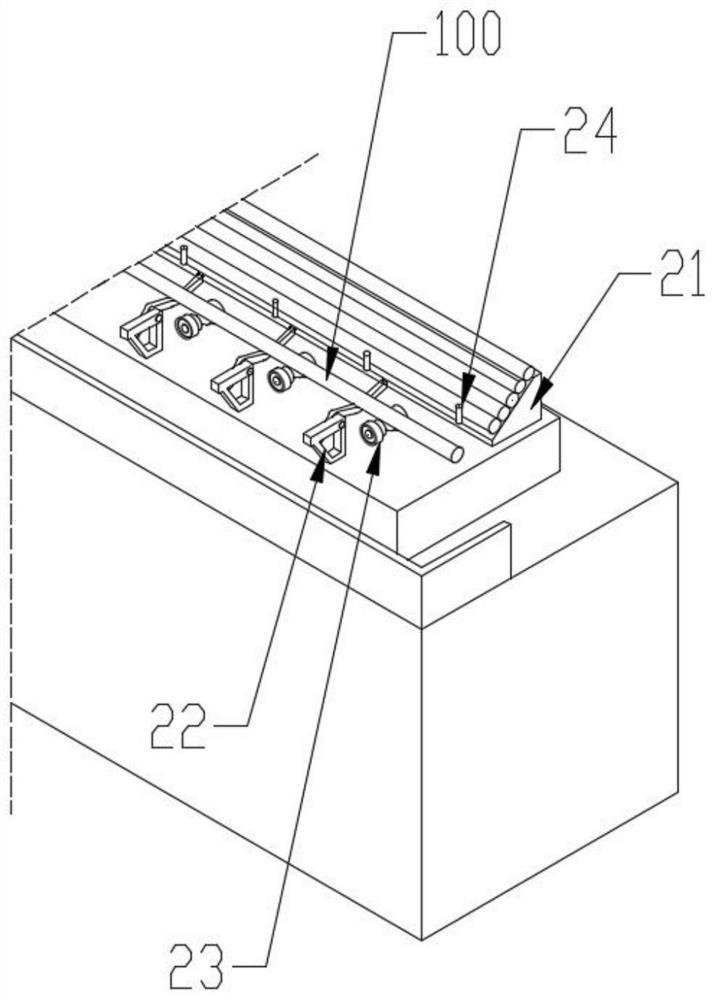

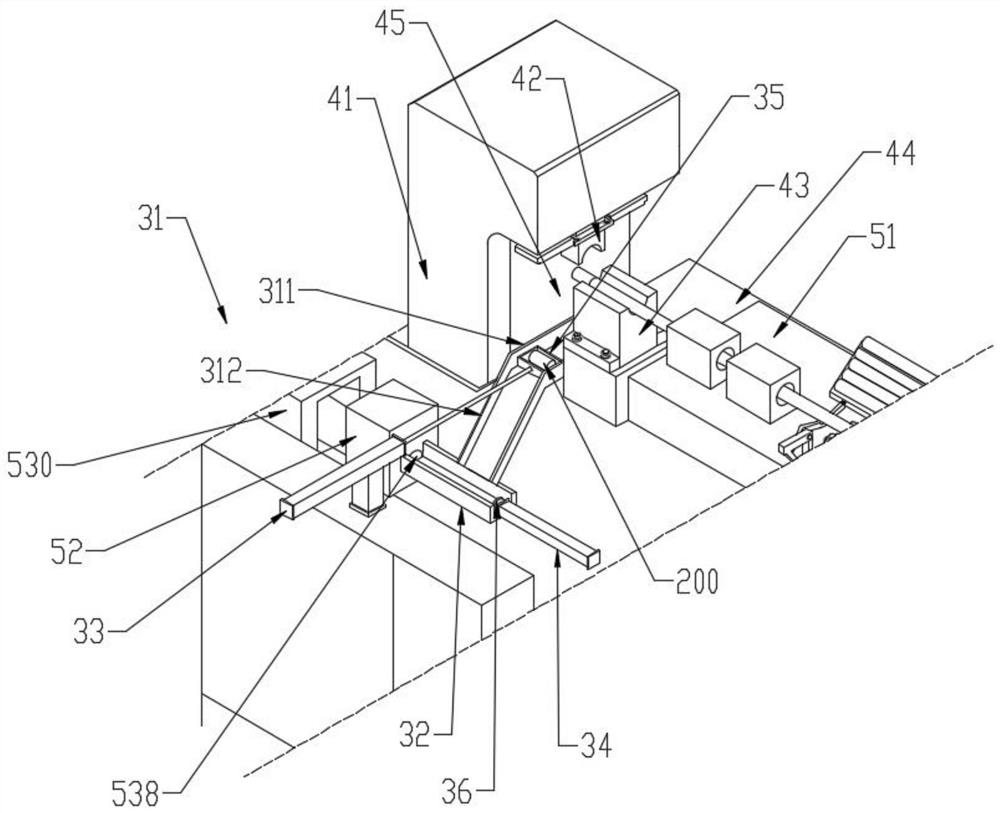

[0048] refer to figure 1 , the present invention discloses a long bar material online automatic blanking device for bearing production, including a production platform 1, a blanking assembly 2 and a material transport mechanism 3 arranged on the production platform 1, and one side of the production platform 1 is installed The escalator, personnel can board the escalator to maintain or monitor each component, and also includes a shearing device 4 and a detection and sorting temperature control system 5; Shearing is to be forged piece 200, and it has feed position 44 and discharge position 45; Detection sorting temperature control system 5 comprises primary heating device, secondary heating device and sorting mechanism 53; Sorting mechanism 53 is used for rejecting temperature or The to-be-forged piece 200 whose weight is in the non-rated range has the to-be-forged piece inlet 538, the to-be-forged piece outlet 539, and the to-be-forged piece rejection port 540; The bar 100 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com