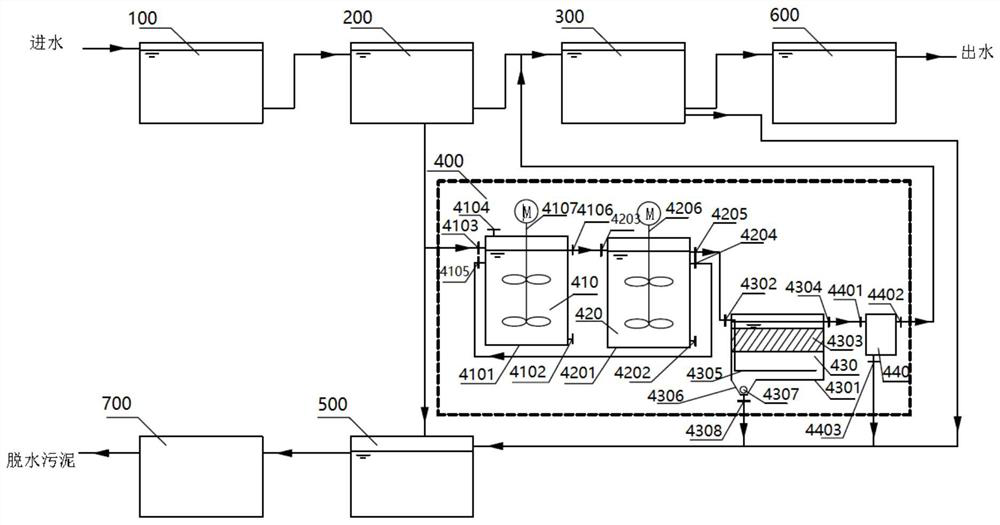

Sludge fermentation-based sewage treatment system and method using internal carbon source

A technology of sewage treatment system and sewage treatment method, applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., which can solve the problem of biochemical denitrification plus large amount of carbon source and discharge of primary sludge Major issues, to achieve the effect of reducing the cost of supplementary carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The primary sludge discharged from the high-density sedimentation tank of a municipal sewage treatment plant in Dalian, which uses multi-stage biological filter as the main process, is used as the sludge fermentation system and enters the sludge conditioning tank. The initial concentration of the primary sludge is MLSS=50460mg / L, the concentration of the sludge after conditioning is MLSS=24895mg / L, and the concentration of dissolved organic matter in the sludge supernatant is SCOD=3950mg / L. Sludge fermentation tank, anaerobic fermentation acid production reaction occurs, the operating parameters of the control fermentation tank are pH 6.01 ~ 7.17, ORP-142.6mv ~ -228.5mv, T = 20 ° C, the hydraulic retention time of fermented sludge in the fermentation tank HRT = 4d, after sludge fermentation, the concentration of the sludge in the fermentation liquid is MLSS=18860mg / L, and the 30% volume ratio fermentation liquid is refluxed, and enters the sludge conditioning tank as the...

Embodiment 2

[0064]The primary sludge discharged from the high-density sedimentation tank of a municipal sewage treatment plant in Dalian, which uses multi-stage biological filter as the main process, is used as the sludge fermentation system and enters the sludge conditioning tank. The initial concentration of primary sludge is MLSS=49320mg / L, after conditioning, the sludge concentration is MLSS=30080mg / L, and the concentration of dissolved organic matter in the sludge supernatant is SCOD=1800mg / L. After conditioning, the sludge enters Sludge fermentation tank, anaerobic fermentation acid production reaction occurs, control the operating parameters of the fermentation tank to be pH 6.74~7.40, ORP-169.6mv~-261.4mv, T=15℃, hydraulic retention time of fermented sludge in the fermentation tank HRT=4d After the sludge is fermented, the concentration of the fermentation liquid sludge is MLSS=25860mg / L, and 20% of the fermentation liquid is refluxed, and enters the sludge conditioning tank as the...

Embodiment 3

[0066] The primary sludge discharged from the high-density sedimentation tank of an urban sewage treatment plant in Qingdao, which uses multi-stage biological filter as the main process, is used as the sludge fermentation system feed and enters the sludge conditioning tank. The initial concentration of primary sludge is MLSS=42500mg / L, after conditioning, the concentration of sludge is MLSS=22700mg / L, the concentration of dissolved organic matter in the sludge supernatant is SCOD=2750mg / L, after conditioning, the sludge enters Sludge fermentation tank, anaerobic fermentation acid production reaction occurs, the operating parameters of the fermentation tank are controlled to be pH 6.08~6.85, ORP-173.9mv~-190.4mv, T=20℃, and the hydraulic retention time of fermented sludge in the fermentation tank HRT=4d After the sludge is fermented, the concentration of the fermentation liquid sludge is MLSS=15560mg / L, 15% of the fermentation liquid is refluxed, and enters the sludge conditioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com