Environment-friendly glass mildew-proof isolation powder

A kind of isolation powder and environment-friendly technology, applied in the field of glass anti-mildew powder, can solve the problems of easy breakage and scratch glass surface, long degradation cycle, waste environmental impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

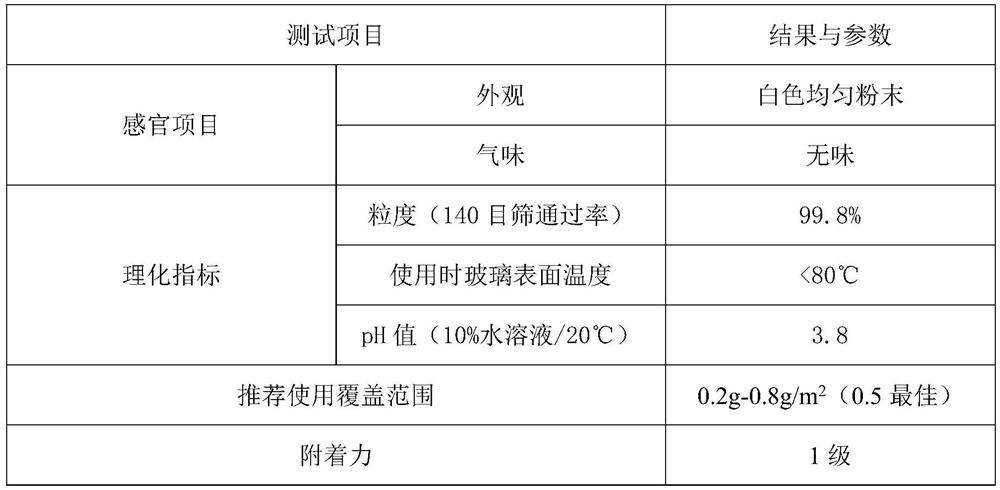

Embodiment 1

[0016] An environment-friendly glass anti-mold isolation powder, which is composed of the following components by weight: 598g of plant fiber powder, 668g of citric acid powder, 669g of maleic acid powder, 8.6g of citrate, 8.5g of maleate, of which plant fiber The powder is composed of 43% coconut shell powder, 37% straw powder, 12% rice bran powder, and 8% sawdust powder. The test results are shown in the figure below:

[0017]

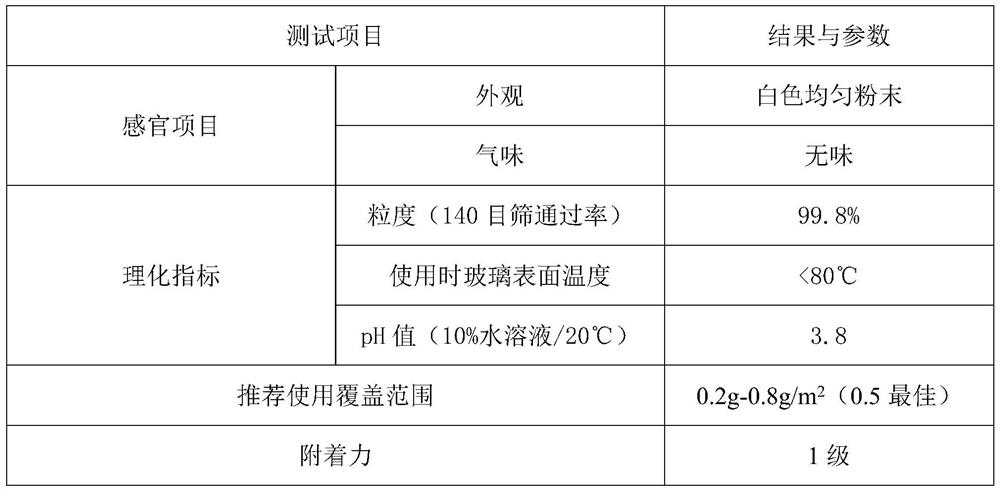

Embodiment 2

[0019] An environment-friendly glass anti-mildew isolation powder, which is composed of the following components by weight percentage: plant fiber powder 725g, citric acid powder 576g, maleic acid powder 582g, citrate 7.9g, maleate 8.3g, wherein plant The fiber powder is composed of 43% of coconut shell powder, 37% of straw powder, 12% of rice bran powder and 8% of sawdust powder.

[0020] The test results are shown in the figure below:

[0021]

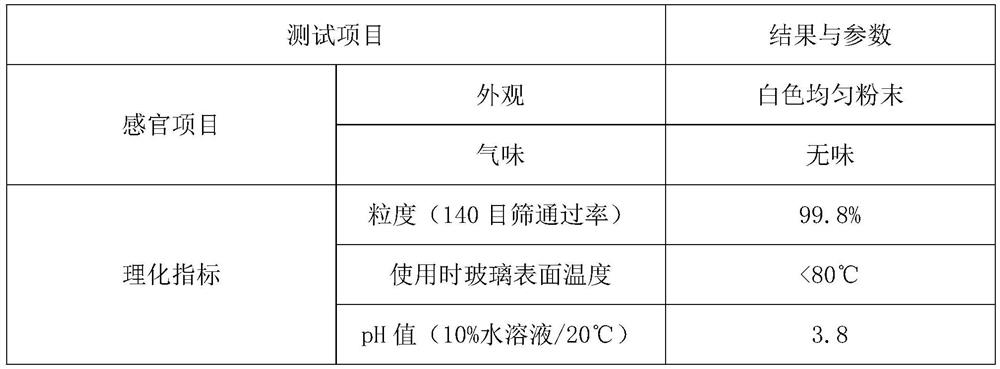

Embodiment 3

[0023] An environment-friendly glass anti-mildew isolation powder is composed of the following components by weight percentage: plant fiber powder 1039g, citric acid powder 375g, maleic acid powder 382g, citrate 8.4g, maleate 8.2g, wherein The plant fiber powder is composed of 43% of coconut shell powder, 37% of straw powder, 12% of rice bran powder and 8% of sawdust powder.

[0024] The test results are shown in the figure below:

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com