Preparation method of organic lake pigment

A technology for organic lakes and pigments, applied in the direction of organic dyes, etc., can solve the problems of low yield of organic lakes and pigments, poor reaction completion, etc., and achieve the effects of improving yield, enhancing yield and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

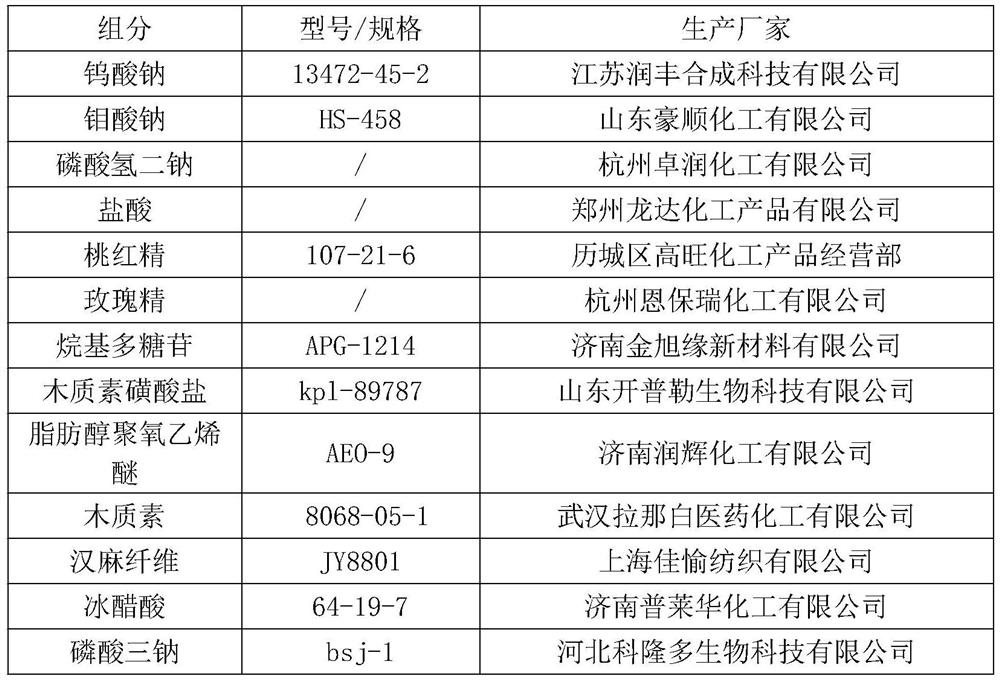

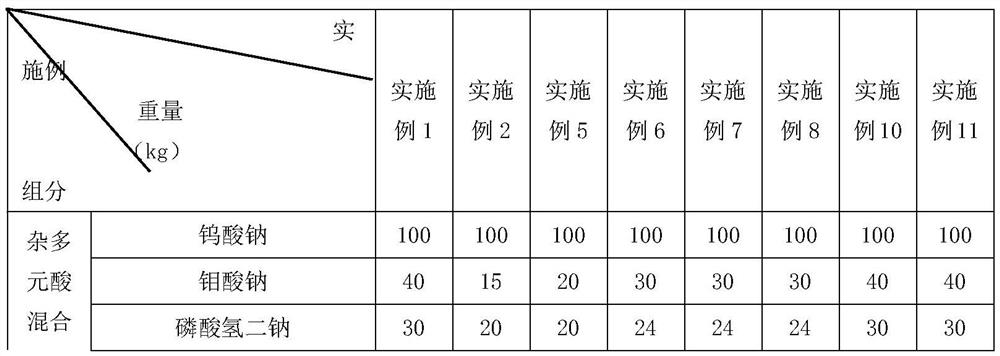

[0041] An organic colorless pigment, the specific component and weight, as shown in Table 2, by the following steps:

[0042] S1: Sodium tungstate, sodium molybdate, sodium hydrogen phosphate, and 80 ° C, the rate of mixing is 600 r / min, mixed with uniform, mixed with a mixture of 20% hydrochloric acid, mixed, mixed, mixed. 500R / min, mixed with mixed hydraulic acid mixture

[0043] S2: At 85 ° C, the water-soluble pigment is added in the mixture in the mixed solution of the heterocolate, and the weight percent is 20% hydrochloric acid and the pigment auxiliary, the stirring speed is 700 r / min, and the stirring is mixed, and stirring is continued for 2 h A mixture of pigment is obtained;

[0044] S3: Press the color filtrate mixture to give the filter cake and filtrate, washed with water for the filter cake, and the washing time is 30 min, and the water after the washing filter is obtained; the water after the washing filter is mixed with the filtrate to mix stirring After th...

Embodiment 2

[0045]Example 2: An organic silica pigment, the difference from Example 1 is that the specific components and weight are different, and the specific components and weights included are shown in Table 2, including the following steps:

[0046] S1: Sodium tungstate, sodium molybdate, sodium hydrogen phosphate, and 100 ° C, mixed stirred at a rate of 600 r / min, mixed with uniform, mixed with 40% hydrochloric acid in weight, mixed stirring speed 500R / min, mixed with mixed mixture after mixing;

[0047] S2: At 95 ° C, the water-soluble pigment is added in the mixed liquid mixture in the heterocolate, and the weight percentage is 40% hydrochloric acid, and the pigment aid is mixed. The stirring speed is 1600r / min, and the stirring is mixed, and stirring is continued for 1 h. A mixture of pigment was obtained later;

[0048] S3: Press the color filtrate mixture to give the filter cake and filtrate, washed with water for the filter cake, and the washing time is 30 min, and the water...

Embodiment 3

[0049] Example 3: An organic starch, distinguishing with Example 1 in that the weight percentage of hydrochloric acid in the step S1 is 30%, and the hydrochloric acid in the step S2 is 25% by weight of hydrochloric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com