Passivation device for mechanical manufacturing

A technology of mechanical manufacturing and telescopic rods, applied in the field of passivation, which can solve the problems of precipitation crystallization, chromium ions easy to adhere to the inner wall of the passivation pool, etc., to achieve uniform density, improve passivation effect, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

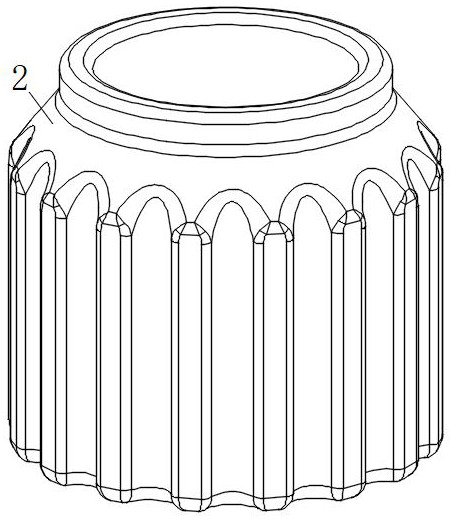

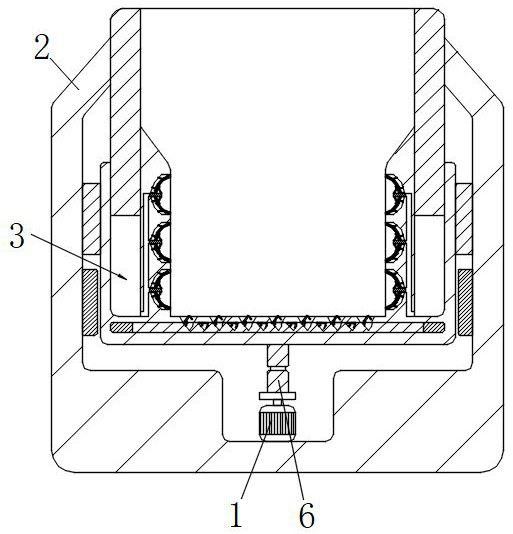

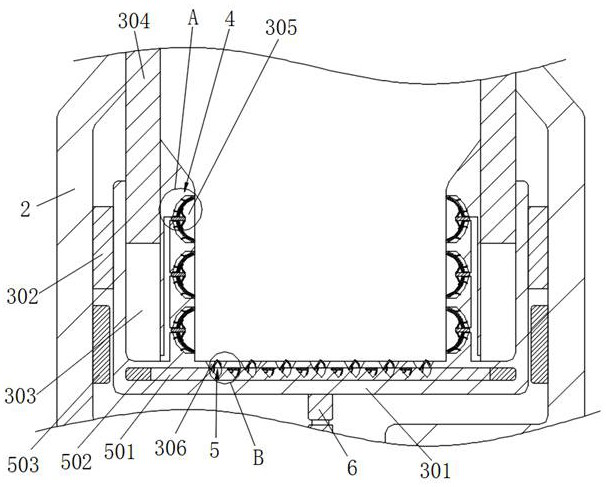

[0024] see Figure 1-6 , the present invention provides a technical solution: a passivation device for machinery manufacturing, including a box body 2, a motor 1 is fixedly connected to the bottom of the inner wall of the box body 2, a telescopic rod 6 is fixedly connected to one end of the motor 1, and a telescopic rod 6 is fixedly connected to the inside of the box body 2. Rotary mixing anti-adhesion mechanism 3;

[0025] The rotary mixing anti-adhesion mechanism 3 includes a passivation pool 301, an internal thread sleeve 302, a cavity 303, a fixed barrel 304, an arc groove 305, a circular groove 306, an arc plate 307, an elastic plate A308, and the bottom of the passivation pool 301 It is fixedly connected with one end of the telescopic rod 6, the outer wall of the passivation pool 301 is threadedly connected with the inner wall of the inner thread sleeve 302, the outer wall of the inner thread sleeve 302 is fixedly connected with the inner wall of the box body 2, the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com