Geometric nonlinear analysis method for CFRP (carbon fiber reinforced plastic) laminated plate in humid and hot environment

A technology for geometrically nonlinear, hot and humid environments, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems that are rarely found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

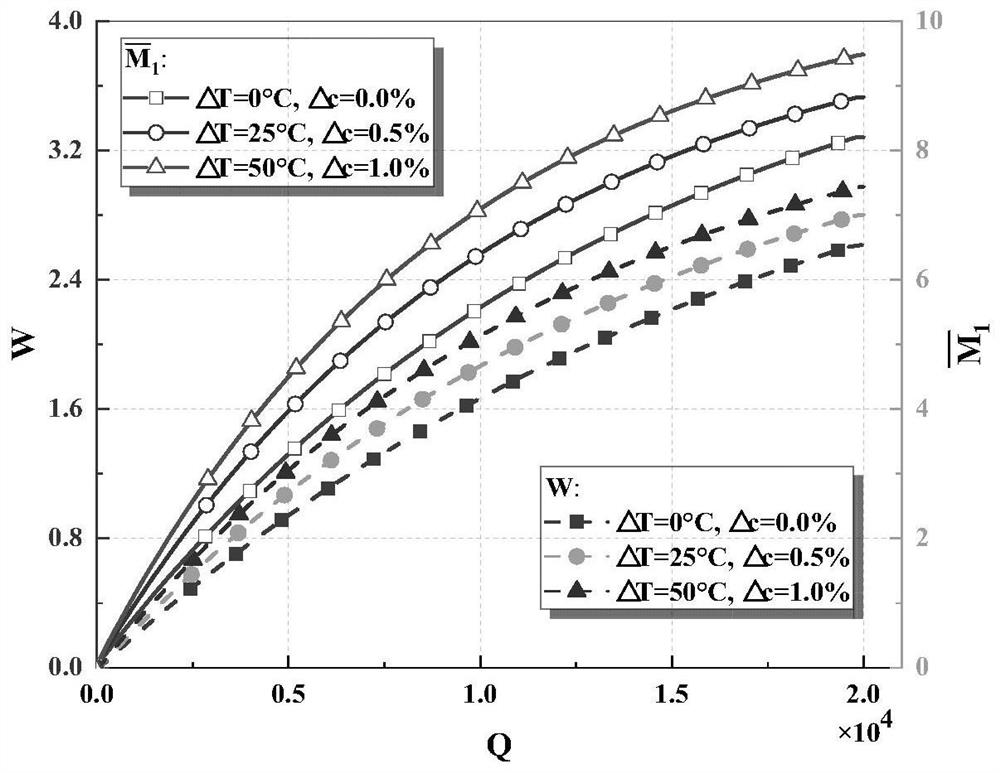

[0058] Embodiment 1: The length, width and height of the CFRP laminate meet 1, 1 and 0.002 respectively; the hot and humid environment satisfies ΔT=0~50C, Δc=0%~1%: when changing the hot and humid environment, the relationship between load-central deflection (W) and load-center bending moment relationship such as figure 1 shown.

[0059] From figure 1 It can be clearly seen that the increase of temperature and humidity increases the bending deflection and bending moment (bending stress) at the same time. Obviously, the hot and humid environment has an adverse effect on the bending behavior of CFRP. It is worth noting that in a hot and humid environment, the most important influence is the temperature factor, while the influence of humidity is very small. If the coefficient of thermal expansion α and the coefficient of wet expansion β are in the same order of magnitude, the hygrothermal force and moment are also in the same order of magnitude, but the difference between ΔT ...

Embodiment 2

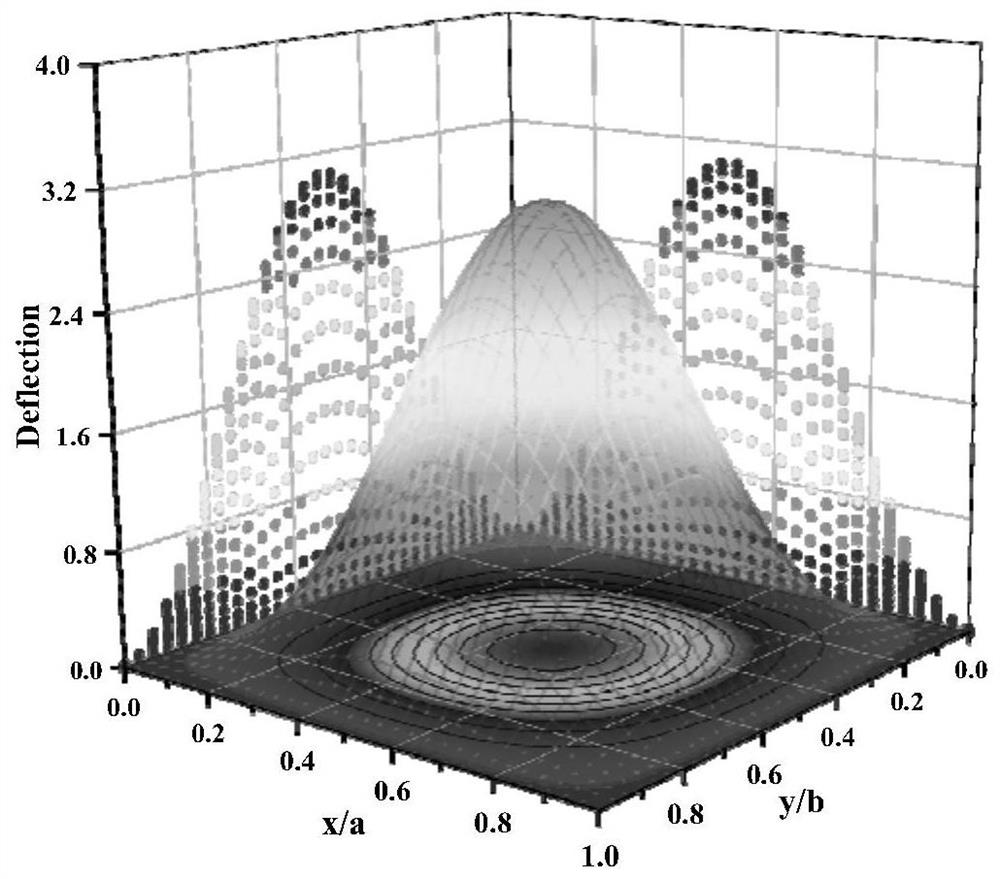

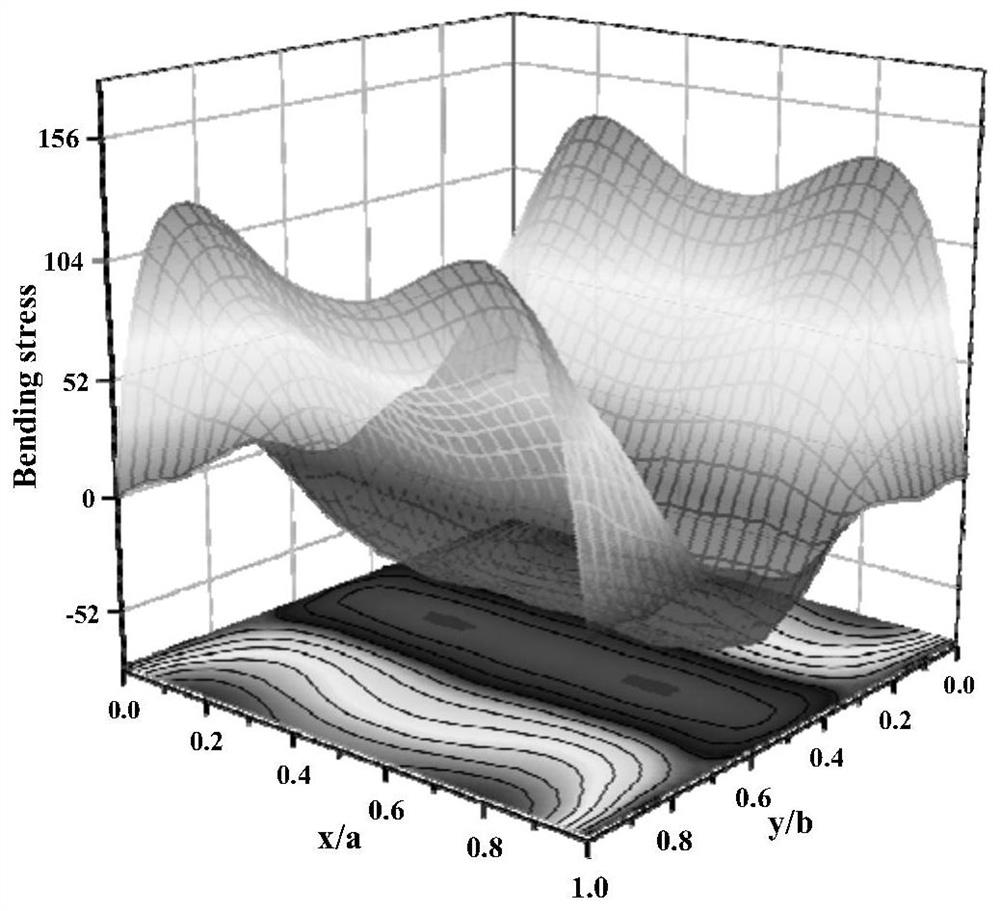

[0060] Example 2: Considering the hot and humid environment ΔT=25C, Δc=0.5%; the three-dimensional deflection distribution of the CFRP plate and the three-dimensional distribution of the bending stress are as follows figure 2 and image 3 , where the corresponding contour lines are shown below.

[0061] figure 2 and image 3 It clearly shows the deformation of the whole CFRP plate under load. The maximum deflection is obviously at the midpoint, as in figure 2 shown. From image 3 The three-dimensional map and contour line in can clearly see the distribution position and magnitude of the bending stress. Since the structure and load of the CFRP plate are symmetrical to the center line, the figure 2 deflection and image 3 The bending stress is also symmetrical about the midline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com