Preparation method of Bi-2223/AgAu superconducting tape with high current-carrying capacity and low thermal conductivity

A technology of bi-2223 and superconducting tape, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of limiting the development of high-temperature superconducting current leads and uneven silver/superinterface , Low density of strip core filaments, etc., to achieve low thermal conductivity, high current-carrying performance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

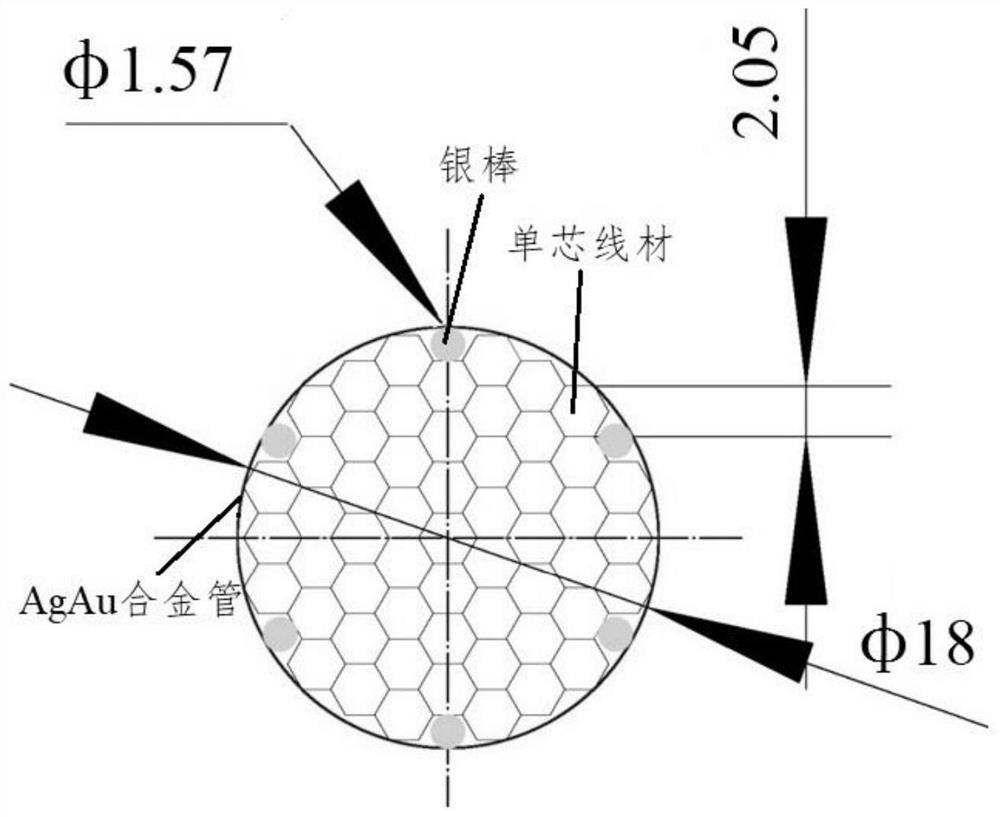

[0028]Step 1. In a glove box with an oxygen volume content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube at a vibration frequency of 40 Hz, and pass the Bi-2223 precursor powder through a metal funnel Fill it into an AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube at the same time, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first filled tube Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1mm, and the mass content of Au element in the AgAu alloy tube is 5%;

[0029] Step 2: Draw the first tube-loading complex obtained in step 1 with a pass ...

Embodiment 2

[0034] This embodiment includes the following steps:

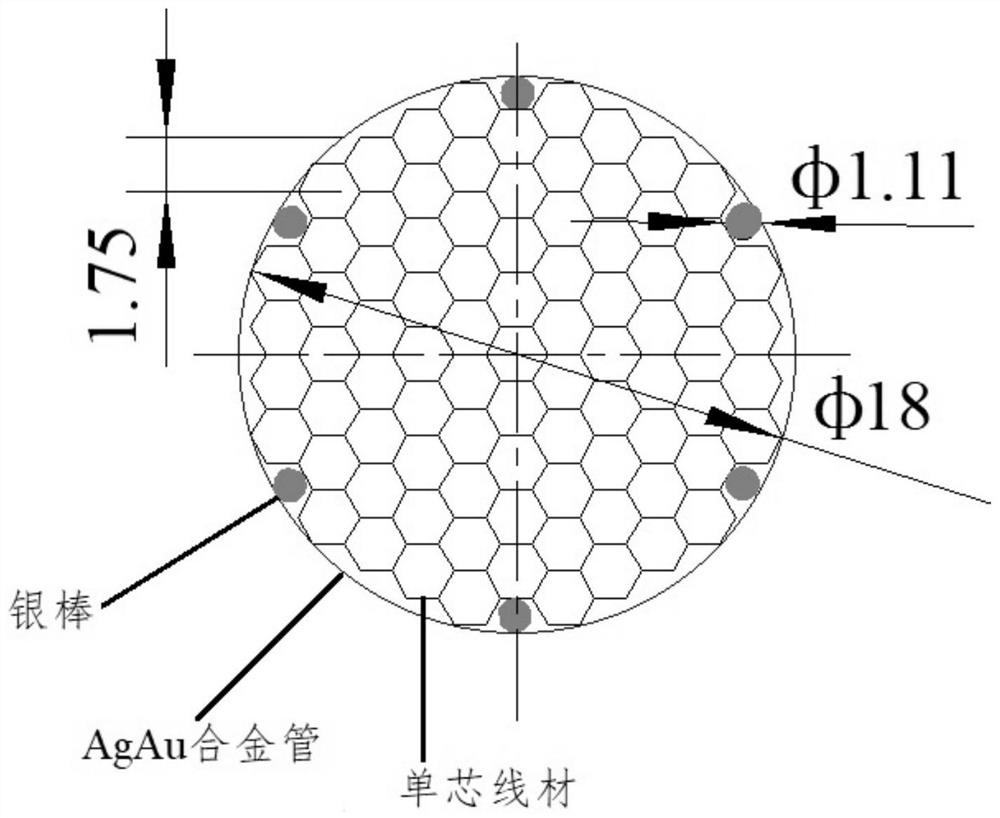

[0035] Step 1. In a glove box with an oxygen volume content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube at a vibration frequency of 40 Hz, and pass the Bi-2223 precursor powder through a metal funnel Fill it into an AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube at the same time, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first filled tube Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1.1mm, and the mass content of Au element in the AgAu alloy tube is 5%;

[0036] Step 2: Draw the first tube-loading complex obtained in step 1 with a pa...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step 1. In a glove box with an oxygen volume content of 7.5% and an equilibrium gas of argon gas with a mass purity of 99.995%, use a vibrating table to vibrate the tube at a vibration frequency of 40 Hz, and pass the Bi-2223 precursor powder through a metal funnel Fill it into an AgAu alloy tube with one end closed, and start the vibrating table to vibrate the AgAu alloy tube at the same time, so that the Bi-2223 precursor powder is filled into the AgAu alloy tube, and then the other end of the AgAu alloy tube is sealed to obtain the first filled tube Composite; the Bi-2223 precursor powder contains Bi-2212 and CaCuO 2 , and Bi-2212 and CaCuO 2 The molar ratio of the AgAu alloy tube is 1:1, the outer diameter of the AgAu alloy tube is 12mm, the wall thickness is 1.5mm, and the mass content of Au element in the AgAu alloy tube is 5%;

[0043] Step 2: Draw the first tube-packing complex obtained in step 1 with a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com