Low-grade waste heat recovery antimonide thermoelectric module with high conversion efficiency and preparation method thereof

A technology for waste heat recovery and thermoelectric modules, which is applied in the manufacture/processing of thermoelectric devices, and lead-out wire materials for thermoelectric devices. Strong anisotropy of thermoelectric properties, low earth reserves, and good self-compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

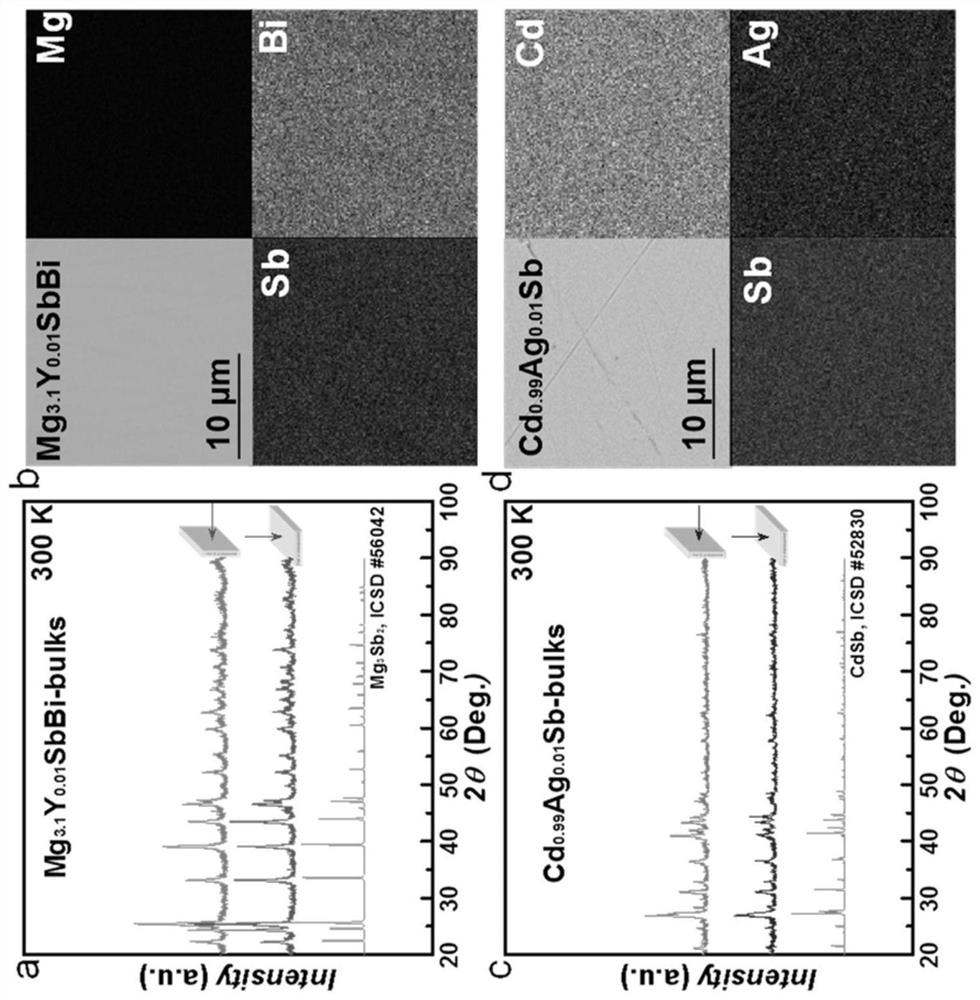

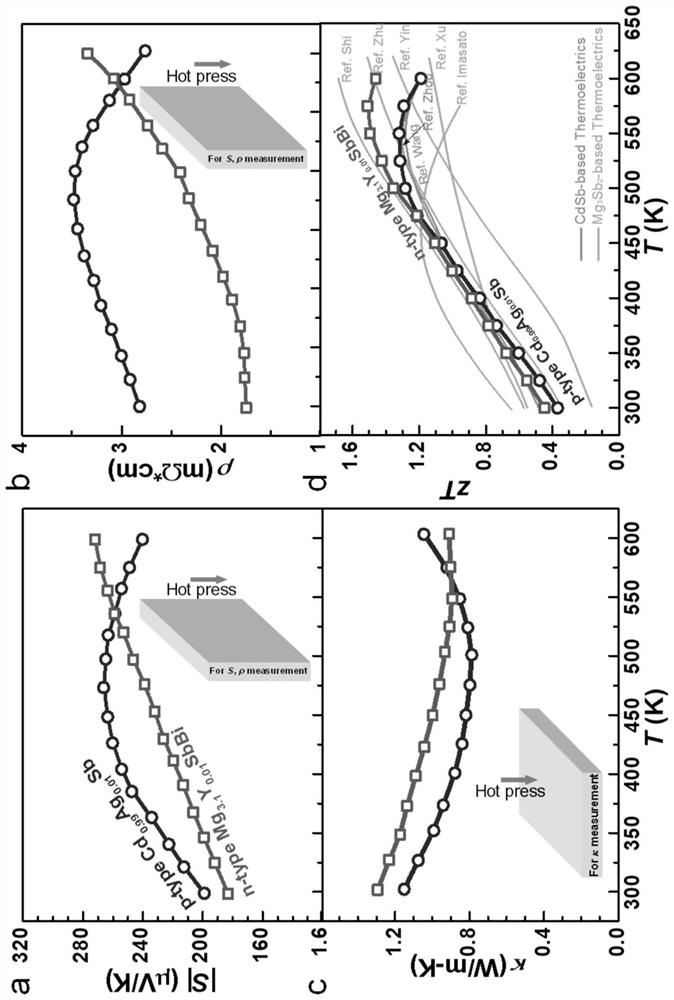

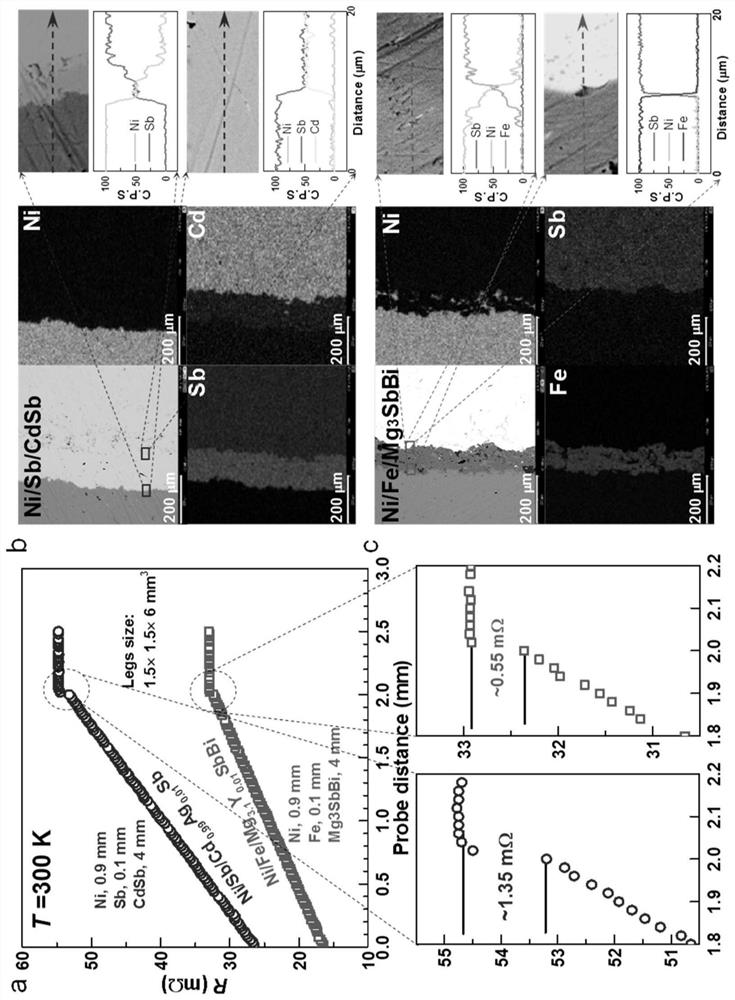

[0055] A low-grade waste heat recovery antimonide thermoelectric module with high conversion efficiency, consisting of n-p thermoelectric elements, the n-type thermoelectric elements are composed of Mg 3.1 Y 0.01 SbBi is used as a thermoelectric semiconductor material, and its composition is recorded as Ni / Fe / Mg 3 SbBi / Fe / Ni, the p-type thermoelectric element is made of Cd 0.99 Ag 0.01 Sb is used as a thermoelectric semiconductor material, and its composition is recorded as Ni / Sb / CdSb / Sb / Ni, where Fe and Sb are Mg 3.1 Y 0.01 SbBi and Cd 0.99 Ag 0.01 Diffusion shielding layer of Sb, Ni as electrode, h Ni (i.e. the thickness of electrode Ni)=0.5-1.5mm (the present embodiment is preferably 0.9mm), h Sb,Fe (i.e. diffusion shielding layer Sb, the thickness of Fe)=0.05-0.3mm (the present embodiment is preferably 0.1mm), h CdSb,Mg3SbBi (that is, the thickness of the thermoelectric semiconductor material)=3-5mm (preferably 4mm in this embodiment), the n-p thermoelectric elemen...

Embodiment 2

[0069] Compared with Example 1, most of them are the same, except that in step (1) of this example, the thickness of the selective electrode layer Ni is 0.5mm, the thickness of the diffusion shielding layers Sb and Fe is 0.05mm, and the thickness of the thermoelectric material is 5mm.

Embodiment 3

[0071] Compared with Example 1, most of them are the same, except Ni / Fe / Mg in the present embodiment step (2) 3 The SbBi / Fe / Ni process conditions are as follows: under a pressure of 90 MPa, the temperature is raised to 600° C. at a rate of 150° C. per minute and kept for 90 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com