a ce 3+ halide electroluminescent device

A halide electroluminescence and electroluminescence technology, which is applied in the fields of electric solid state devices, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of poor performance of new non-lead metal halide materials, and achieve high-efficiency electroluminescence applications, Wide application range and high photoluminescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

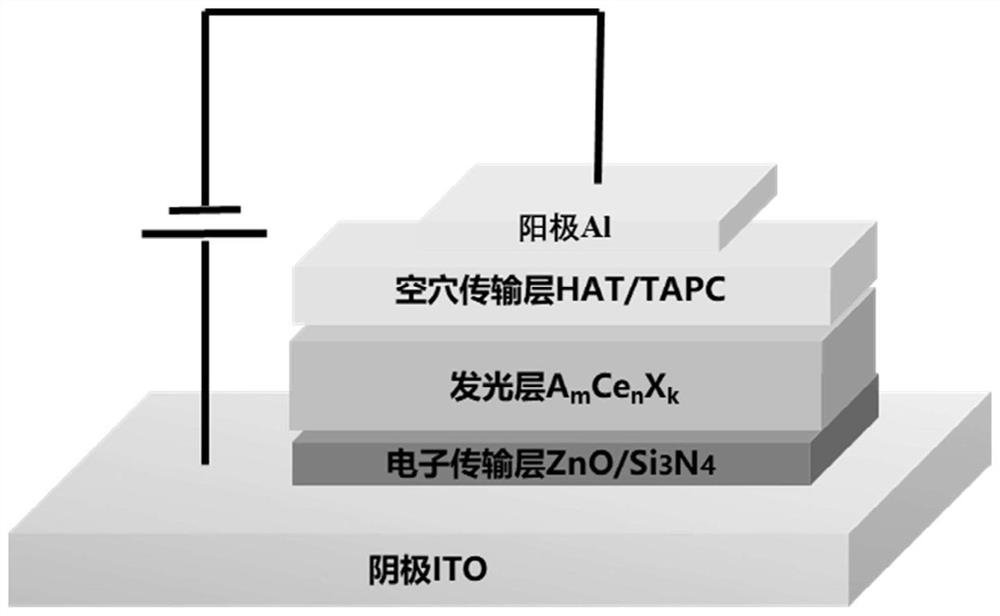

[0037] In this embodiment, the light-emitting layer material is Cs 3 CaBr 6 The violet LED device of the material is taken as an example, and its specific preparation method includes the following steps:

[0038] a) Ultrasonic cleaning of the ITO substrate with detergent, deionized water, acetone and absolute ethanol in sequence for half an hour each time;

[0039] b) Using magnetron sputtering method on ITO, sputtering ZnO with a thickness of about 40nm;

[0040] c) Coating a layer of 10nm Si on ZnO by MOCVD 3 N 4 film;

[0041] d) will be plated Si 3 N 4 The substrate of the film is placed in the evaporation glove box, and the vacuum degree is evacuated to 4*10 -5 Below Pa, the substrate is heated to 200°C, and CeBr is evaporated at a speed of 0.1nm / s by co-evaporation 3 , CsBr was evaporated at a speed of 0.3nm / s, and the total thickness was about 100nm. In the dual-source co-evaporation process, using the spontaneous crystallization process, the CsBr and CeBr 3 T...

Embodiment 2

[0049] In this embodiment, the light-emitting layer material is Cs 3 CaBr 6 The violet LED device of the material is taken as an example, and its specific preparation method includes the following steps:

[0050] a) Clean the base ITO ultrasonically with detergent, deionized water, acetone and absolute ethanol in sequence, half an hour each time;

[0051] b) Using magnetron sputtering method on ITO, sputtering ZnO with a thickness of about 40nm;

[0052] c) A layer of 10nm Al is plated on ZnO by ALD 2 o 3 film;

[0053] d) will be plated Al 2 o 3 The substrate of the film is placed in the evaporation glove box, and the vacuum degree is evacuated to 4*10 -5 Below Pa, the substrate is heated to 200°C, and CeBr is evaporated at a speed of 0.1nm / s by co-evaporation 3 , CsBr was evaporated at a speed of 0.3nm / s, and the total thickness was about 100nm. In the dual-source co-evaporation process, using the spontaneous crystallization process, the CsBr and CeBr 3 The reactio...

Embodiment 3

[0057] In this embodiment, the light-emitting layer material is Cs 3 CaBr 6 The violet LED device of the material is taken as an example, and its specific preparation method includes the following steps:

[0058] a) Clean the base ITO ultrasonically with detergent, deionized water, acetone and absolute ethanol in sequence, half an hour each time;

[0059] b) Using magnetron sputtering method on ITO, sputtering ZnO with a thickness of about 40nm;

[0060] c) Coating a layer of 10nm NiO thin film on ZnO by MOCVD method;

[0061] d) Put the substrate coated with NiO film into the evaporation glove box, and pump the vacuum to 4*10 -5 Below Pa, the substrate is heated to 200°C, and CeBr is evaporated at a speed of 0.115nm / s by co-evaporation 3 , CsBr was evaporated at a speed of 0.16nm / s, and the total thickness was about 100nm. In the dual-source co-evaporation process, using the spontaneous crystallization process, the CsBr and CeBr 3 The reaction produces Cs 3 CaBr 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com