Electric socket and electric socket safety cover for humid environment

A wet environment, electric socket technology, applied in the direction of the circuit, electrical components, base/housing, etc., can solve the problems of humid air entering, scrapping of plugs and sockets, and affecting the use of sockets, so as to improve moisture resistance, reduce content, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

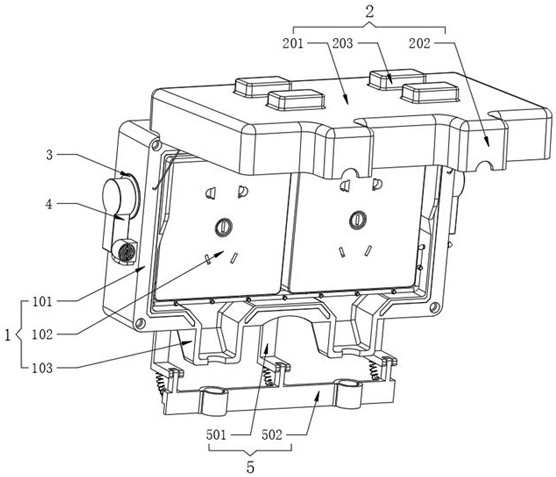

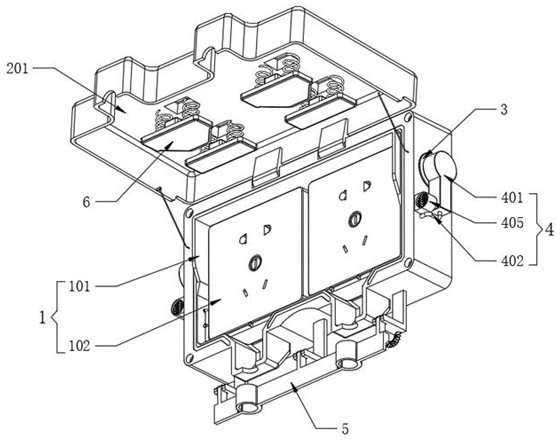

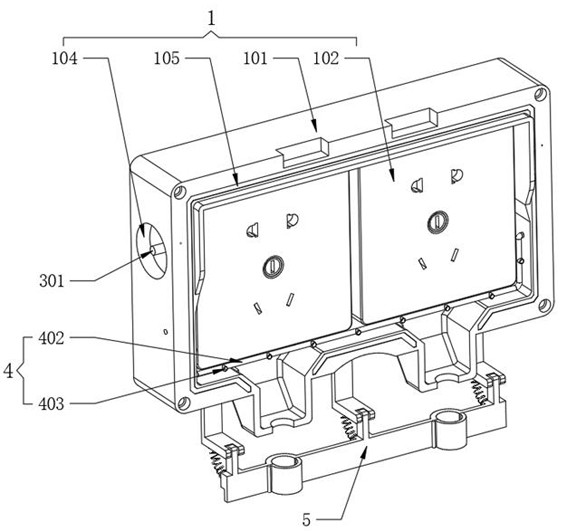

[0042] see Figure 1-5 , an electric socket and an electric socket safety cover for a humid environment, comprising an electric socket assembly 1, a safety cover 2, a trigger 3 and an inflator 4;

[0043] refer to figure 2 and image 3 The electric plug board assembly 1 also includes an outer casing 101, the side walls of the outer casing 101 are fixedly provided with side assembly grooves 104, and the side assembly grooves 104 provide the installation space for the trigger 3, and both sides of the outer casing 101 are fixedly assembled with inner A sealing strip 105 is fixedly embedded in the side wall of the plugboard 102 and the outer casing 101, and the sealing strip 105 improves the sealing performance of the inside of the plugboard.

[0044] refer to figure 1 , the safety cover 2 also includes a cover 201, the cover 201 is rotatably mounted on one side of the outer shell 101, the setting of the cover 201 makes the electric plug board have the characteristics of water...

Embodiment 2

[0049] see figure 1 and Image 6 , an electric socket and an electric socket safety cover for a humid environment, including a wire protector 5;

[0050] refer to Figure 5 , the wire protector 5 is fixedly installed on the bottom of the outer shell 101, the wire protector 5 also includes a turning bar 502, the bottom of the outer shell 101 is fixedly welded with a bottom bar 501 at an equal distance, the turning bar 502 is connected to the bottom bar 501 in rotation, and the turning bar 501 is turned over Both sides of the outer wall of the rod 502 are rotated and installed with cable sleeves 503, and the inner wall of the turning rod 502 is equidistantly fixedly connected with a suction spring 504, and the top of the suction spring 504 is fixedly connected with the bottom rod 501. The effect of stabilizing the wire is achieved by the cooperation of the first wire shell 103 and the second wire shell 202, and then the wire sleeve 503 is rotated to fix the wire. When the wire...

Embodiment 3

[0053] see figure 2 and Figure 7 , an electric socket and an electric socket safety cover for a humid environment, comprising a socket protection prompter 6;

[0054] refer to Figure 5 , the jack protection prompter 6 is evenly installed on the inner wall of the cover 201, the jack protection prompter 6 also includes an inner movable plate 601, the surface of the inner movable plate 601 is fixedly bonded with a water-absorbing pad 602, and the water-absorbing pad 602 is movable and fitted inside On the surface of the interposer 102, when a jack on the interposer 102 is in an idle state, the inner movable plate 601 will be close to the interposer 102, and the water-absorbing pad 602 will be attached to the jack, thereby preventing water vapor from entering Inside the interposer 102, in addition, using the water absorption capacity of the water-absorbing pad 602, the socket can be dried at the same time, which further improves the moisture-proof effect. The other surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com