Packaging method of film bulk acoustic resonator

A thin-film bulk acoustic wave and packaging method technology, which is applied to electrical components, impedance networks, etc., can solve the problems of high production cost and complicated packaging process of thin-film bulk acoustic wave resonators, and achieves simplified device production costs, good acoustic wave confinement, and simplification. The effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

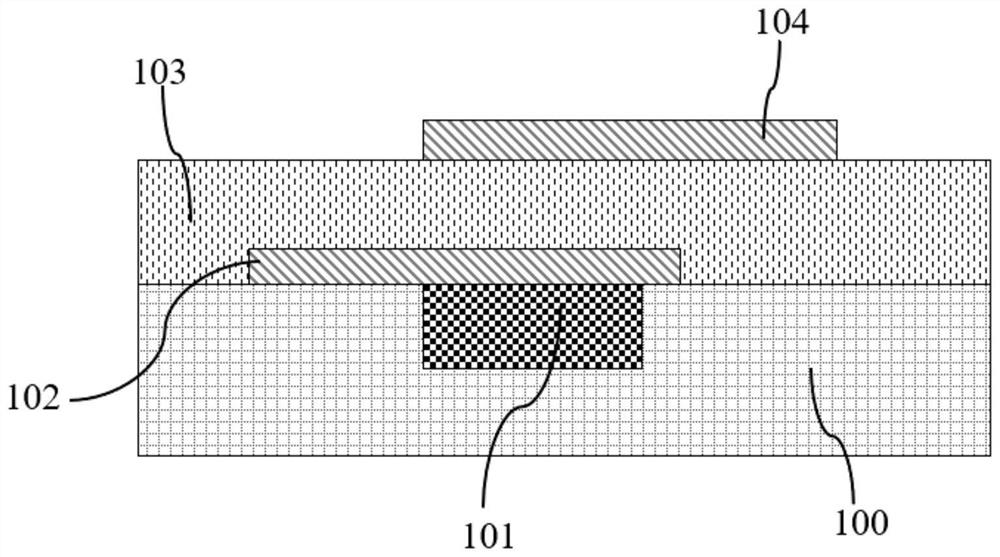

[0037]A packaging method for a thin film bulk acoustic resonator, the packaged thin film bulk acoustic resonator includes a substrate 100 and a piezoelectric oscillation stack; the piezoelectric oscillation stack includes a first electrode 102, a piezoelectric layer 103 and a second electrode 104; The substrate 100 is provided with a first cavity; the first electrode 102 is located on the substrate 100 and covers the first cavity; the piezoelectric layer 103 covers the first electrode 102 and the substrate 100; the second electrode 104 is located in the piezoelectric layer 103, such as figure 1 Shown; the specific steps of the method are as follows:

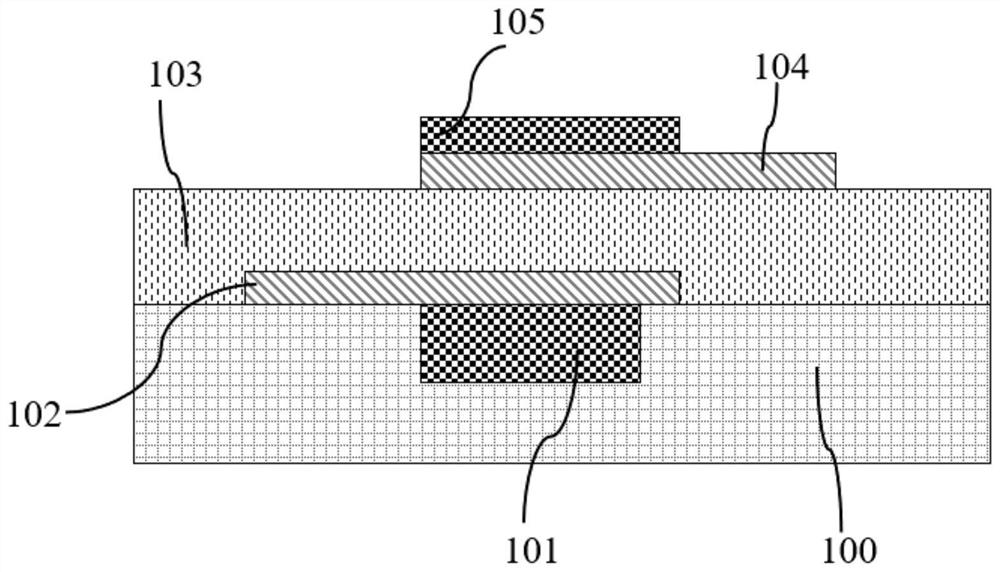

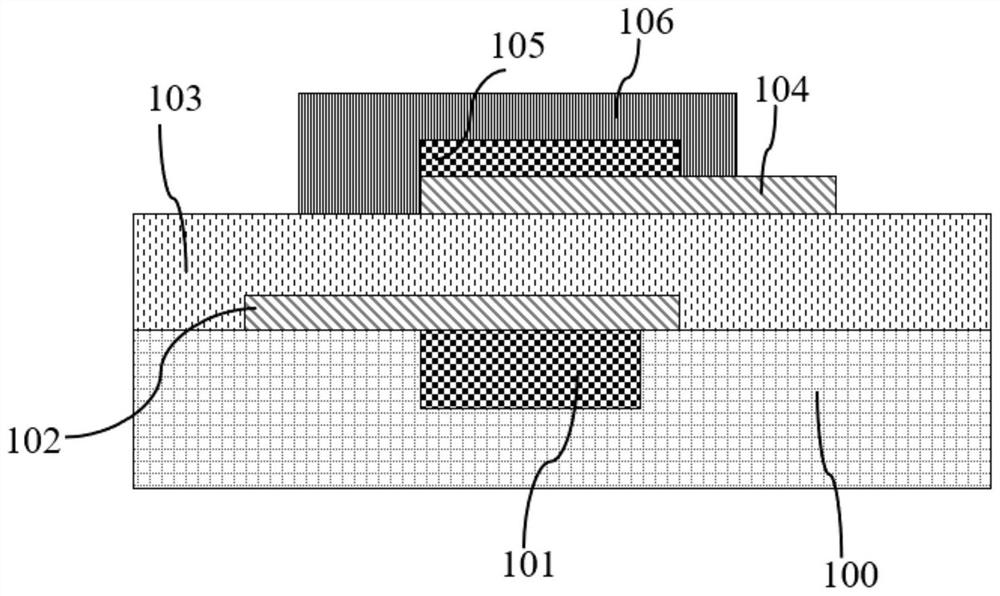

[0038] Step 1: If figure 2 As shown, a packaging sacrificial layer 105 is deposited on the surface of the second electrode 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com