Multipurpose double-hydraulic-motor simplified driving system for tree transplanting machine

A drive system, dual hydraulic technology, applied in the direction of fluid pressure actuation system components, servo motors, servo motor components, etc., can solve the problems of limited excavation, increased weight of the mechanism, limited size, etc., and achieves a streamlined and reasonable transmission structure. , avoid excessive wear and improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This multi-purpose dual hydraulic motor tree moving machine simplifies the drive system. When preparing before the operation, start the hydraulic pump 73, and the hydraulic pump 73 will pump the hydraulic oil from the oil tank 70 through the filter 71 to filter and the shut-off valve 72 from the output of the hydraulic pump 73. Oil port arrives check valve two 77 and relief valve 76 places.

[0073] First connect the middle position of the reversing valve 1 75, and connect the right position of the reversing valve 2 78. At this time, the hydraulic oil passes through the P2 port and A2 port of the reversing valve 2 78 from the oil outlet of the check valve 2 77 At the same time, the hydraulic oil in the rodless chamber of the hydraulic cylinder 2 enters the oil tank 70 through the B2 port and the T2 port of the reversing valve 2 78, realizing the piston rod of the hydraulic cylinder 2. Contraction, the piston rod of hydraulic cylinder 2 shrinks to realize the opening of ...

Embodiment 2

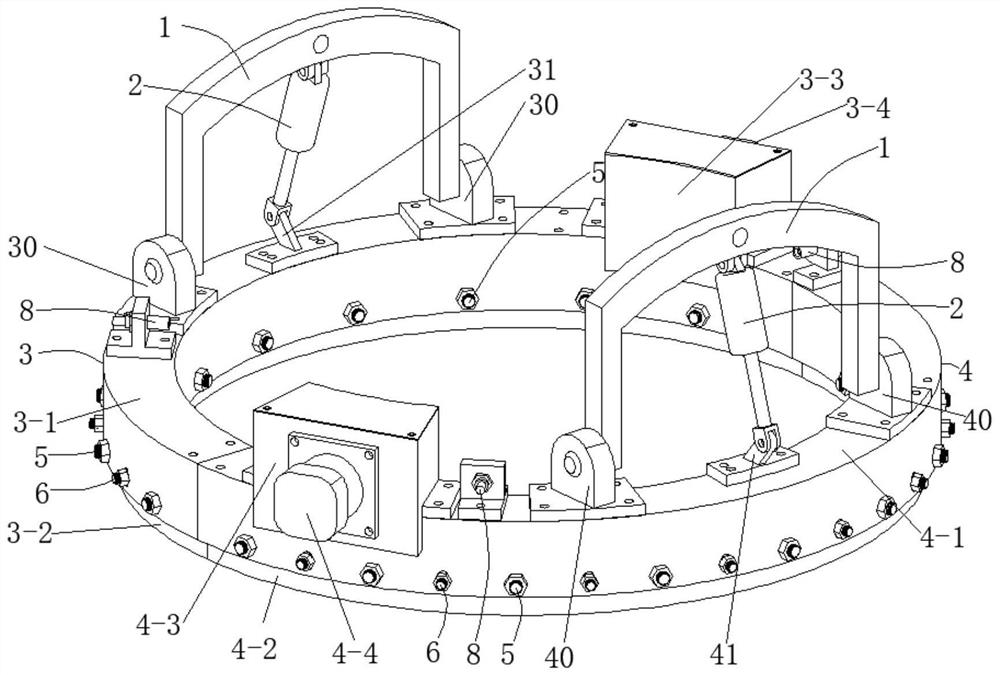

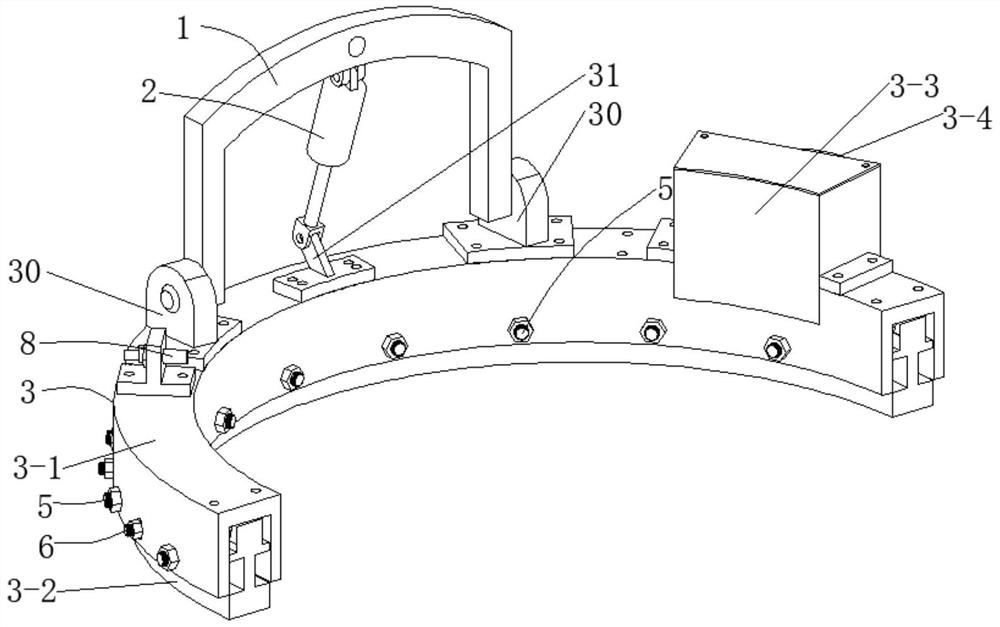

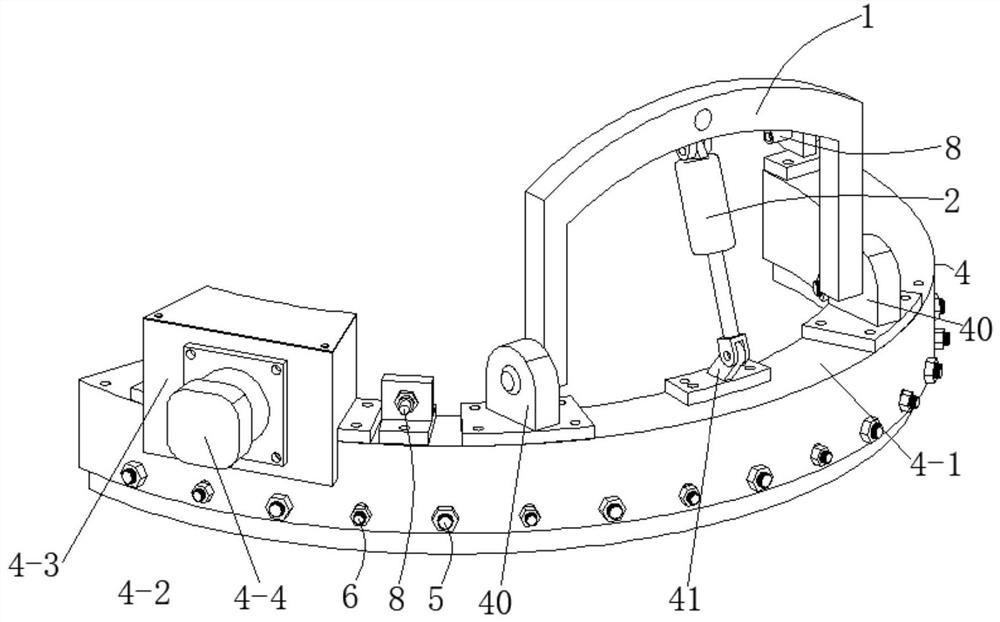

[0078] The multi-purpose double hydraulic motor tree moving machine has a simplified drive system, the upper end of the left rotary ring 3-2 is provided with a semicircular end face gear ring 304, and the upper end face of the right rotary ring 4-2 is provided with a semicircular end face gear ring 304, so The left gear 3-40 meshes on the upper side of the left rotary circle 3-2, and the right gear 4-40 meshes on the upper side of the right rotary circle 4-2, avoiding the arrangement of the left gear 3-40 and the right gear 4-40 The inside is in contact with the bark, resulting in broken bark, which improves the integrity of the tree after excavation; in addition, during the working process, the semicircular end face gear ring 304 provided on the upper end surface of the left rotary ring 3-2 and the upper end face of the right rotary ring 4-2 The ring gear 304 with a semicircular end face is always upward, and the transmission heat of the tooth surface contact will make the lub...

Embodiment 3

[0080]The multi-purpose dual-hydraulic motor tree moving machine simplifies the drive system. The middle position of the reversing valve 75 is connected, and the right position of the reversing valve 2 78 is connected. At this time, the hydraulic oil passes through the oil outlet of the check valve 2 77. The P2 port and A2 port of the reversing valve 2 78 enter the rod chamber of the hydraulic cylinder 2, and at the same time, the hydraulic oil in the rodless chamber of the hydraulic cylinder 2 enters the oil tank through the B2 port and the T2 port of the reversing valve 2 78 In 70, the shrinkage of the piston rod of the hydraulic cylinder 2 is realized, and the shrinkage of the piston rod of the hydraulic cylinder 2 realizes the opening of the left drive system 3 through the middle connection seat 31, so that the hinge seat 30 on the left drive system 3 surrounds the lifting lug 1 The lower end rotates to open; the piston rod of the hydraulic cylinder 2 shrinks and realizes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com