Method and equipment for reducing secondary reaction in MTO reaction

A secondary reaction and reaction technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve problems such as cost increase, and achieve the effect of high low-carbon olefin selectivity and high raw material conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

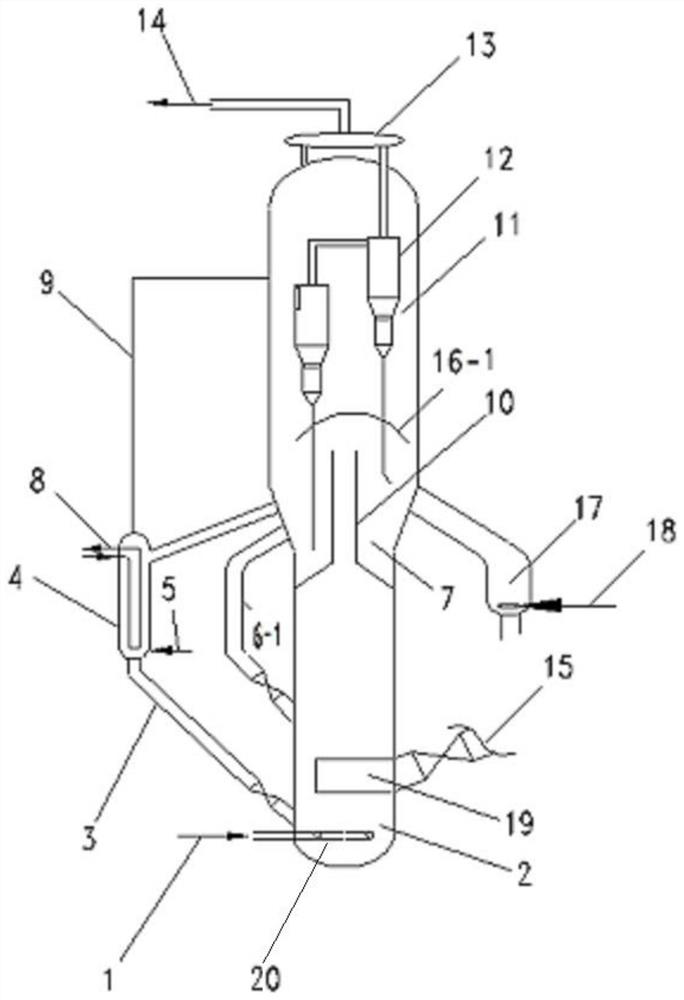

[0082] Such as figure 1 As shown, the raw material that is mainly methanol enters the fast bed reaction zone 2, contacts with the catalyst comprising silicon aluminum phosphorus molecular sieve, generates the gas phase stream including light olefins, C4 hydrocarbons and the catalyst to be born, and then accelerates through the accelerating tube 10 and is set It is in contact with the arc-shaped baffle 16-1 above the acceleration tube. The arc-shaped baffle has an arc of 120° and is convex. The distance between the highest point of the center of the baffle and the outlet of the acceleration tube is 1 / 8 of the height of the acceleration tube. 56% of the solid catalyst running track changes at 120°C. After the remaining catalyst and gas are separated by the cyclone separator 12, the gas phase stream enters the separation section through the pipeline 14. The catalyst to be raw is divided into at least three parts. The heat extractor 4 returns to the bottom of the fast bed reaction...

Embodiment 2

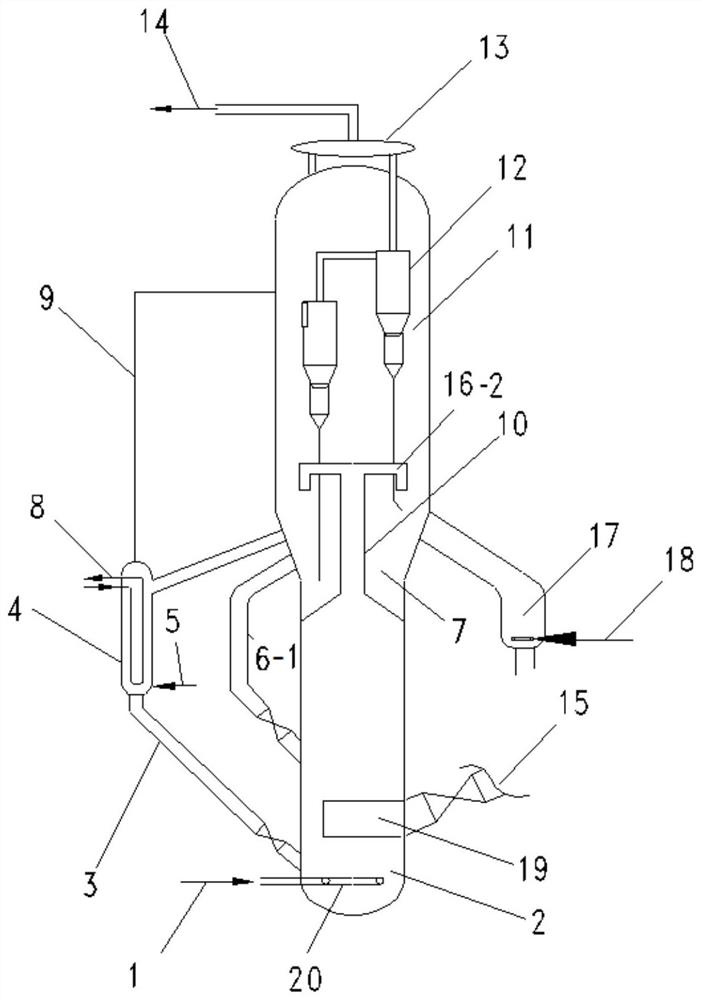

[0087] Such as figure 2 As shown, the raw material that is mainly methanol enters the fast bed reaction zone 2, contacts with the catalyst comprising silicon aluminum phosphorus molecular sieve, generates the gas phase stream including light olefins, C4 hydrocarbons and the catalyst to be used, and then enters the gas phase after being accelerated by the accelerating tube 10. Solid rapid separation cyclone separator 16-2, 85% of the solid catalyst running track changes at 180°C, after the remaining catalyst and gas are separated by cyclone separator 12, the gas phase stream enters the separation section through pipeline 14, and the raw catalyst is separated at least It is divided into three parts, the first part returns to the bottom of the fast bed reaction zone 2 after being heated by the external heat extractor 4 of the reactor, the second part returns to the fast bed reaction zone through the reactor circulation inclined pipe 6-1, and the third part enters the stripping A...

Embodiment 3

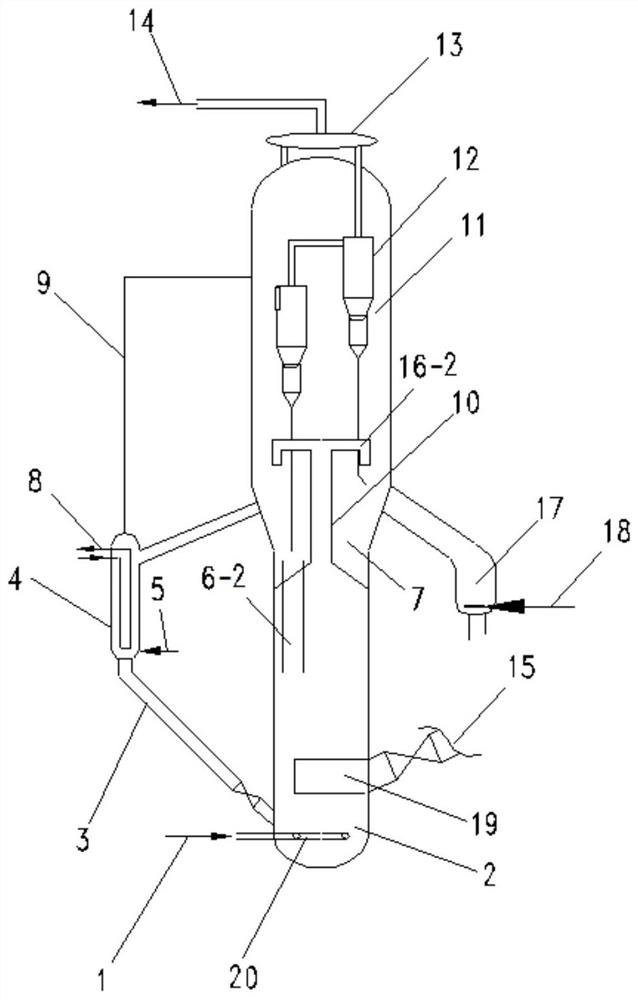

[0090] Such as image 3 As shown, the raw material that is mainly methanol enters the fast bed reaction zone 2, contacts with the catalyst comprising silicon aluminum phosphorus molecular sieve, generates the gas phase stream including light olefins, C4 hydrocarbons and the catalyst to be used, and then enters the gas phase after being accelerated by the accelerating tube 10. Solid rapid separation cyclone separator 16-2, 85% of the solid catalyst running track changes at 180°C, after the remaining catalyst and gas are separated by cyclone separator 12, the gas phase stream enters the separation section through pipeline 14, and the raw catalyst is separated at least It is divided into three parts, the first part returns to the bottom of the fast bed reaction zone 2 after being heated by the external heat extractor 4 of the reactor, the second part returns to the fast bed reaction zone through the overflow pipe 6-2, and the third part enters the stripper 17 After stripping, ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com