TiAl alloy capable of inhibiting generation of ordered omega phase and preparation method of TiAl alloy

An alloy, an inevitable technology, applied in the field of high-temperature γ-TiAl-based alloys, can solve problems such as poor high-temperature performance, and achieve the effect of improving microstructure stability, simple process, and good microstructure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

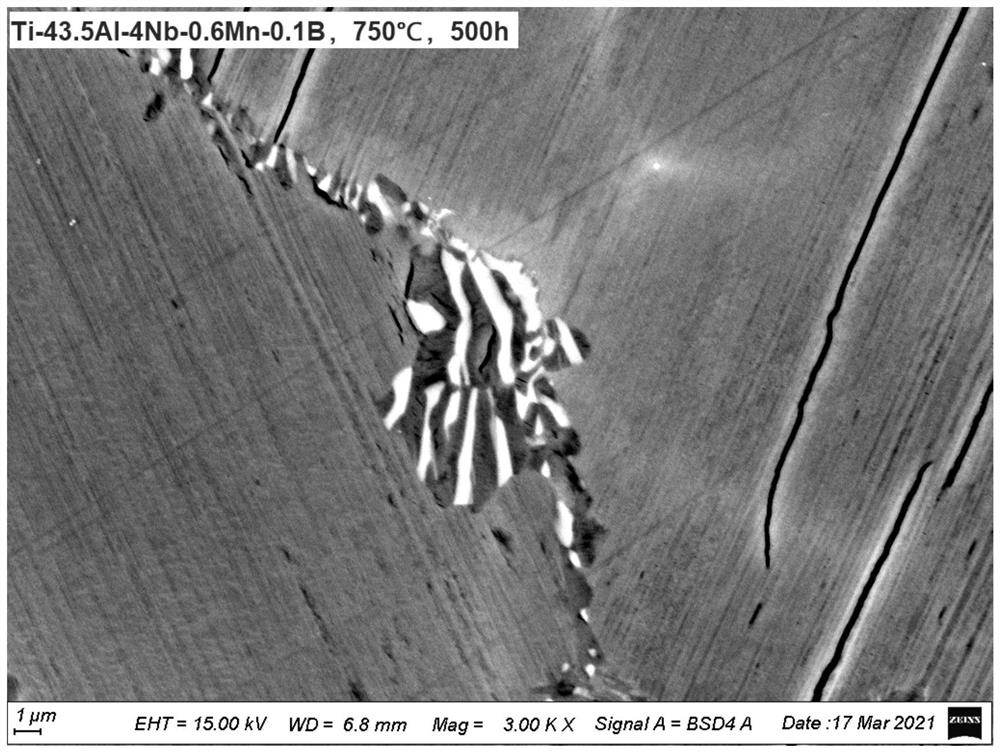

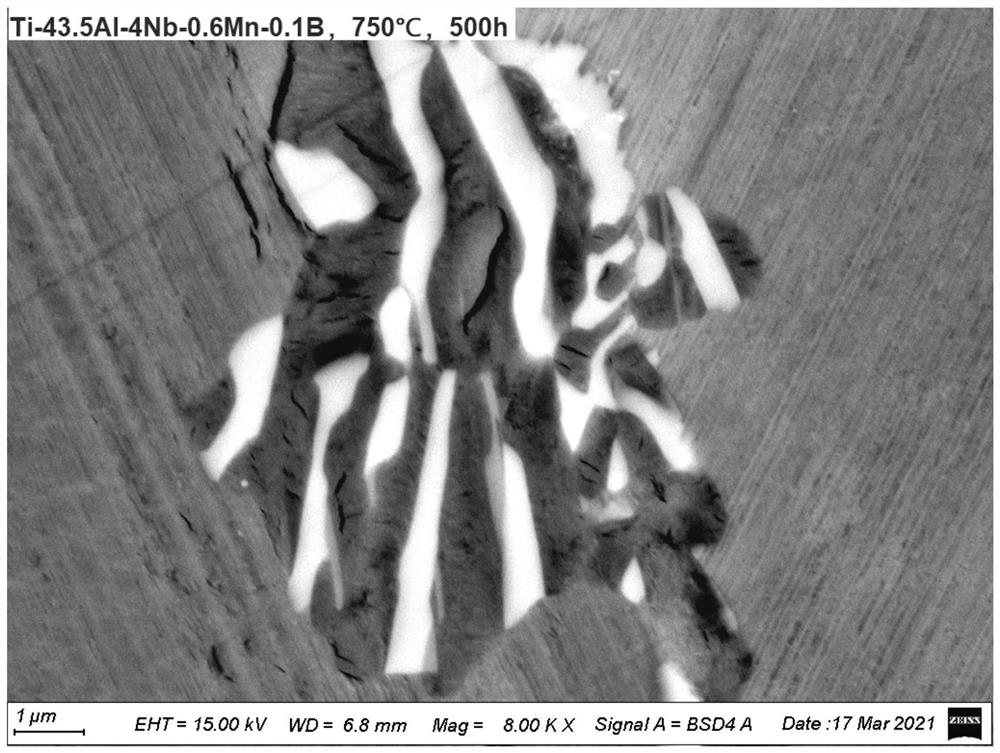

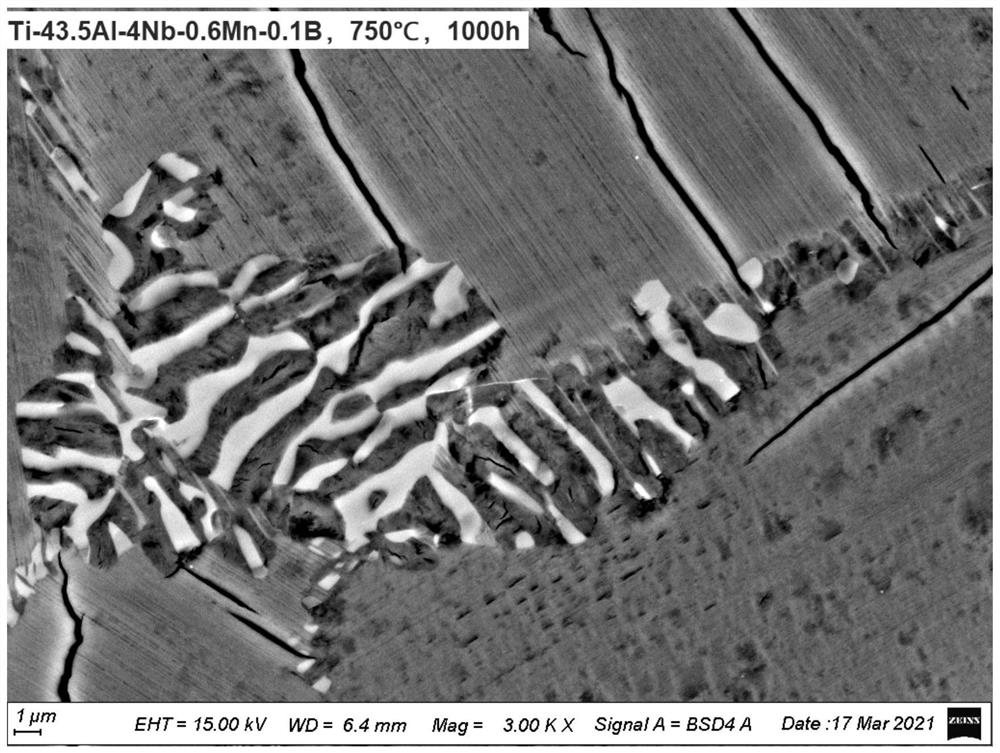

[0044] This embodiment is a TiAl alloy that can inhibit the formation of an ordered ω phase. The atomic percentage is: Ti-43.5Al-4Nb-0.6Mn-0.1B, and the balance is Ti; the preparation of the TiAl alloy is realized through the following steps:

[0045] Step 1) Ingredients

[0046] Zero-grade sponge titanium, A00-grade high-purity aluminum, Nb-Al master alloy, high-purity manganese, and high-purity boron are mixed according to the composition ratio of 51.8at%Ti, 43.5at.%Al, 4at.%Nb, 0.6at.%Mn , 0.1at.% B is prepared into a sample weighing about 40g and mixed evenly;

[0047] Step 2) Melting the ingot

[0048] Place the sample in step 1) in the crucible of a vacuum non-consumable arc melting furnace for melting, and melt it five times. From the second melting, the ingot needs to be turned over for each melting to ensure the uniformity of the ingot , the smelting vacuum degree is lower than 0.1Pa, and the smelting current is controlled within an appropriate range. After five tim...

Embodiment 2

[0056] This embodiment is a TiAl alloy that can inhibit the formation of an ordered ω phase. The atomic percentage is: Ti-43.5Al-4Nb-0.8Mn-0.1B, and the balance is Ti; the preparation of the TiAl alloy is realized through the following steps:

[0057] Step 1) Ingredients

[0058] Zero-grade sponge titanium, A00-grade high-purity aluminum, Nb-Al master alloy, high-purity manganese, and high-purity boron are mixed according to the composition ratio of 51.6at%Ti, 43.5at.%Al, 4at.%Nb, 0.8at.%Mn , 0.1at.% B is prepared into a sample weighing about 40g and mixed evenly;

[0059] Step 2) Melting the ingot

[0060] Place the sample in step 1) in the crucible of a vacuum non-consumable arc melting furnace for melting, and melt it five times. From the second melting, the ingot needs to be turned over for each melting to ensure the uniformity of the ingot , the smelting vacuum degree is lower than 0.1Pa, and the smelting current is controlled within an appropriate range. After five tim...

Embodiment 4

[0080] This embodiment is a TiAl alloy that can inhibit the formation of an ordered ω phase. The atomic percentage is: Ti-44.5Al-4Nb-0.6Mn-0.1B, and the balance is Ti; the preparation of the TiAl alloy is realized through the following steps:

[0081] Step 1) Ingredients

[0082] Zero-grade sponge titanium, A00-grade high-purity aluminum, Nb-Al master alloy, high-purity manganese, and high-purity boron are mixed according to the composition ratio of 50.8at%Ti, 44.5at.%Al, 4at.%Nb, 0.6at.%Mn , 0.1at.% B is prepared into a sample weighing about 40g and mixed evenly;

[0083] Step 2) Melting the ingot

[0084] Place the sample in step 1) in the crucible of a vacuum non-consumable arc melting furnace for melting, and melt it five times. From the second melting, the ingot needs to be turned over for each melting to ensure the uniformity of the ingot , the smelting vacuum degree is lower than 0.1Pa, and the smelting current is controlled within an appropriate range. After five tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com