High-temperature color developing method and device for copper oxide

A copper oxide, high temperature technology, applied in decorative arts, processes for producing decorative surface effects, metal material coating processes, etc., can solve the problems of copper changing properties, dispersion of copper oxide high-temperature color developing devices, and difficult operation. , to achieve the effect of convenient and simple operation of the device, improved production efficiency and strong safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

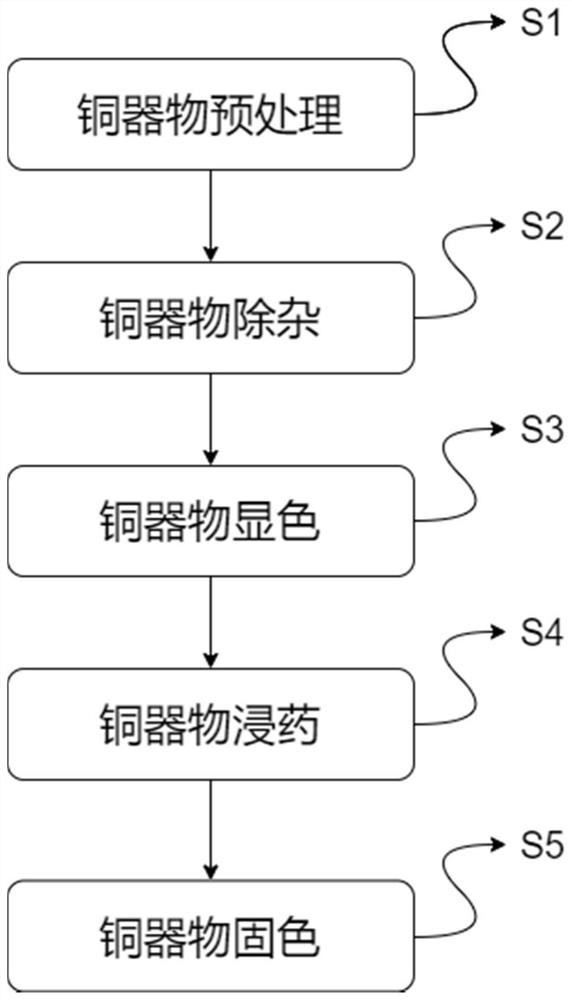

[0041] Refer to attached figure 1 As shown, the present invention provides a technical solution: a high-temperature color development method of copper oxide, comprising the following steps:

[0042] S1, pretreatment of copper utensils, polishing the surface of copper utensils to present a bright color;

[0043] S2, removing impurities from copper utensils, apply silicon dioxide evenly on the surface of the polished copper utensils, place it in the color development device and heat for 5 minutes, then take it out and rinse it with clean water;

[0044] S3, the color of the copper utensils, put it in the color developing device again to heat the copper utensils evenly and slowly, observe that the surface of the copper utensils is orange-yellow, then increase the temperature slowly, and observe that the surface of the copper utensils is bright red, keep the temperature for 1 minute and then turn off the heating device , take out the copper objects to cool naturally;

[0045] S4...

Embodiment 2

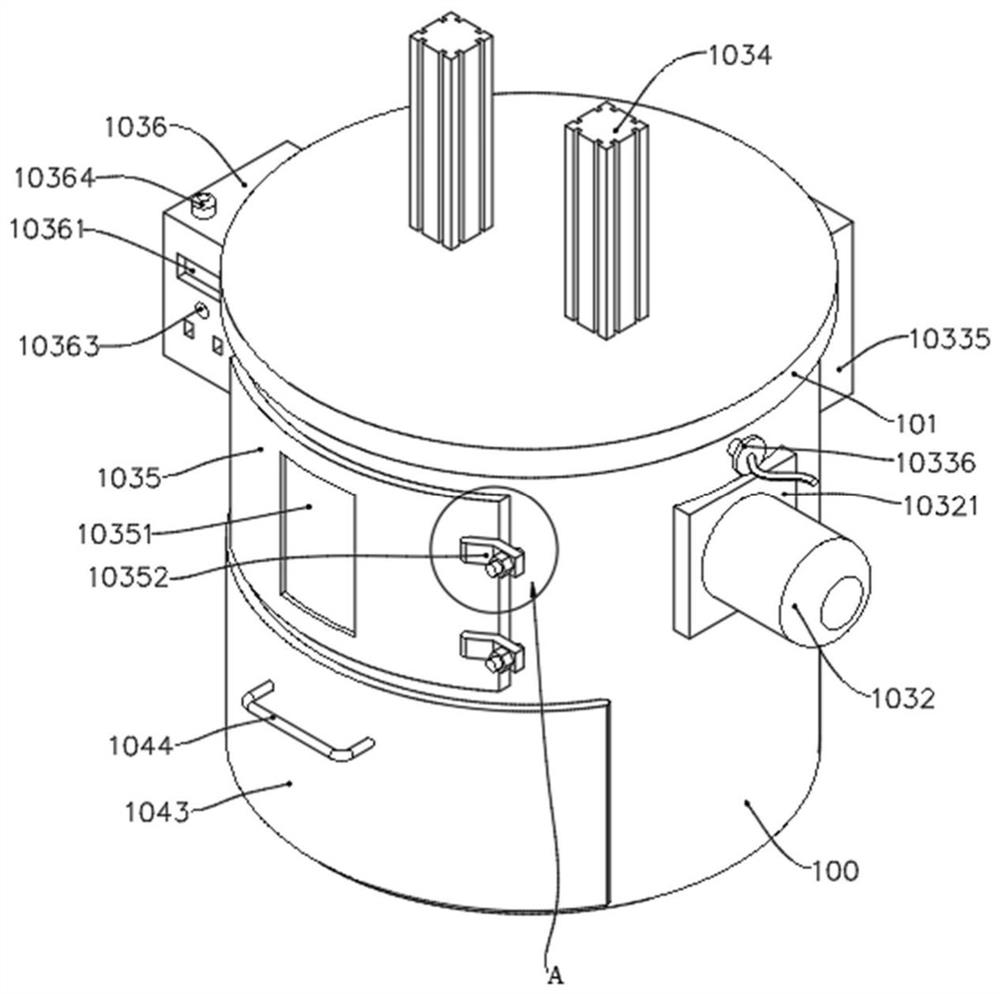

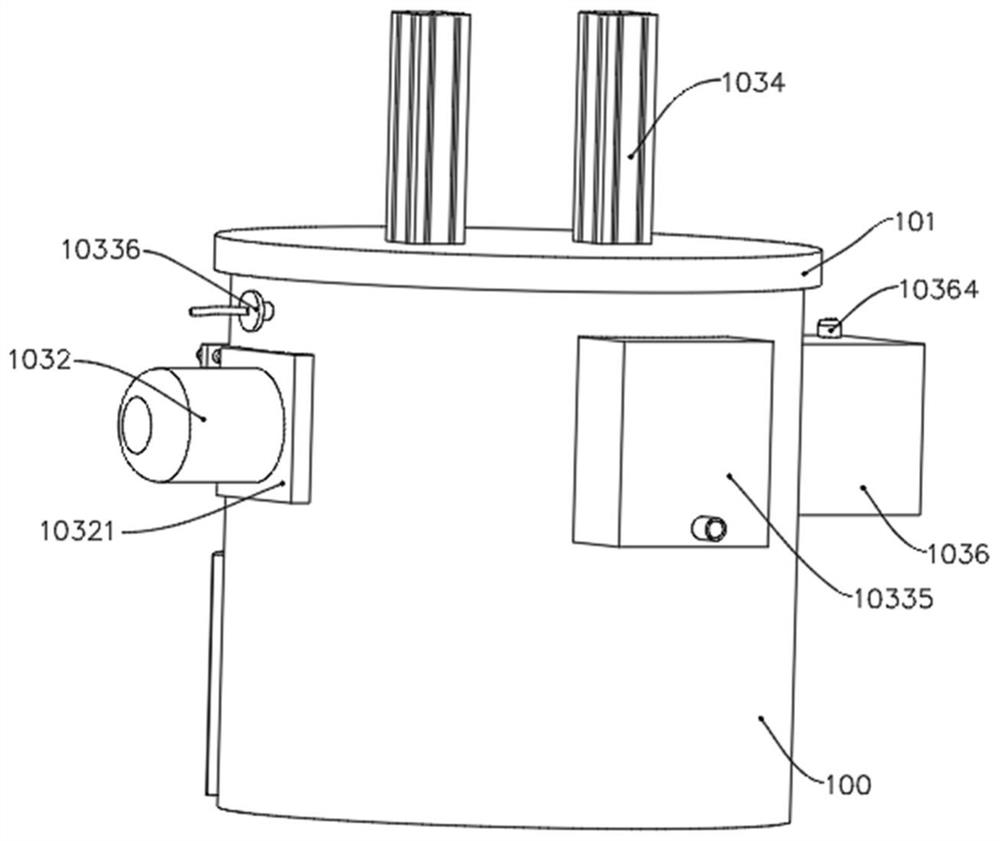

[0052] Refer to attached Figure 2-8 As shown, a copper oxide high-temperature color development device includes a housing 100, the housing 100 is a hollow cylinder structure, a force ring 101 is provided on the outside of the top of the housing 100, and a partition plate is provided inside the housing 100 102, the partition plate 102 divides the housing 100 into a heating chamber 103 and a drug immersion chamber 104, and the heating chamber 103 is arranged on the upper part of the drug immersion chamber 104;

[0053] Refer to attached Figure 1-8 As shown, the bottom of the heating chamber 103 is provided with a movable plate 1031, the movable plate 1031 is a cylindrical structure, the outside of the movable plate 1031 is provided with conical teeth 10311, and the top of the movable plate 1031 is provided with at least two sets of positioning columns 10312, each set The positioning column 10312 is a symmetrical combination of two sets of positioning bars. The positioning col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com