Modified polyvinyl alcohol, and moisture-absorbing and strength-retaining agent containing same and used for corrugated cartons

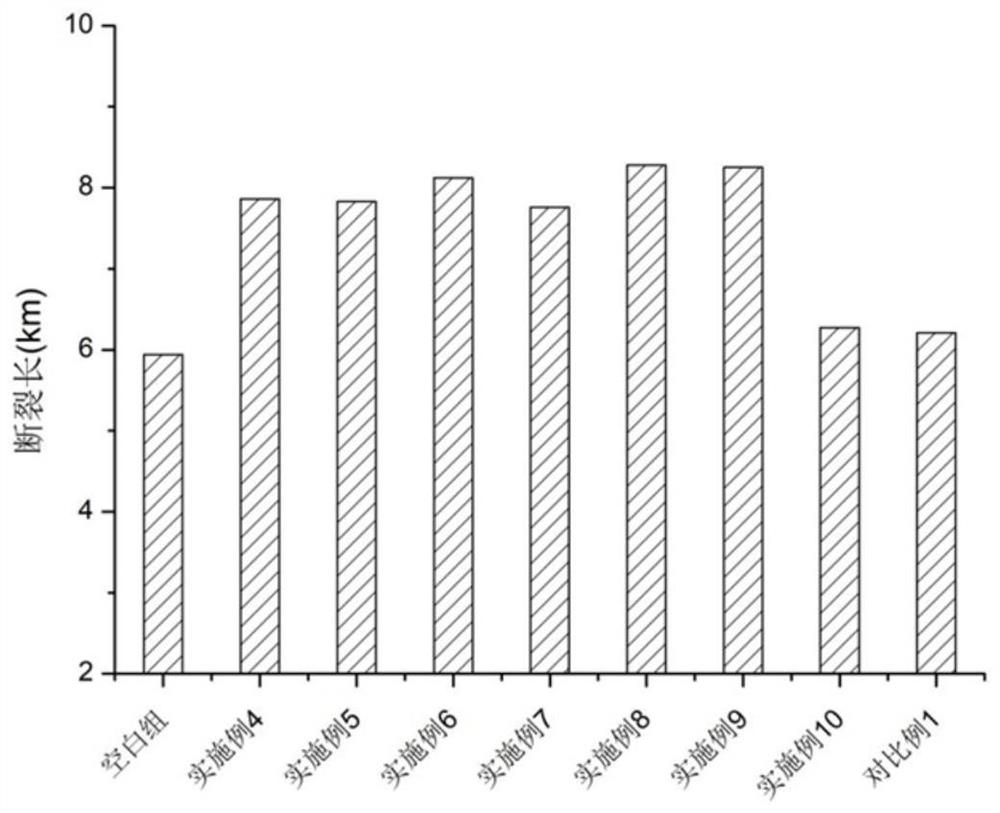

A technology for polyvinyl alcohol and corrugated boxes, which is applied in the direction of adding reinforcing agents, manufacturing rigid/semi-rigid containers, papermaking, etc., which can solve the problems of easy damage, limited application, and increased packaging costs, so that it is not easy to bend and damage, and improves moisture resistance. Performance, the effect of improving the ring compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

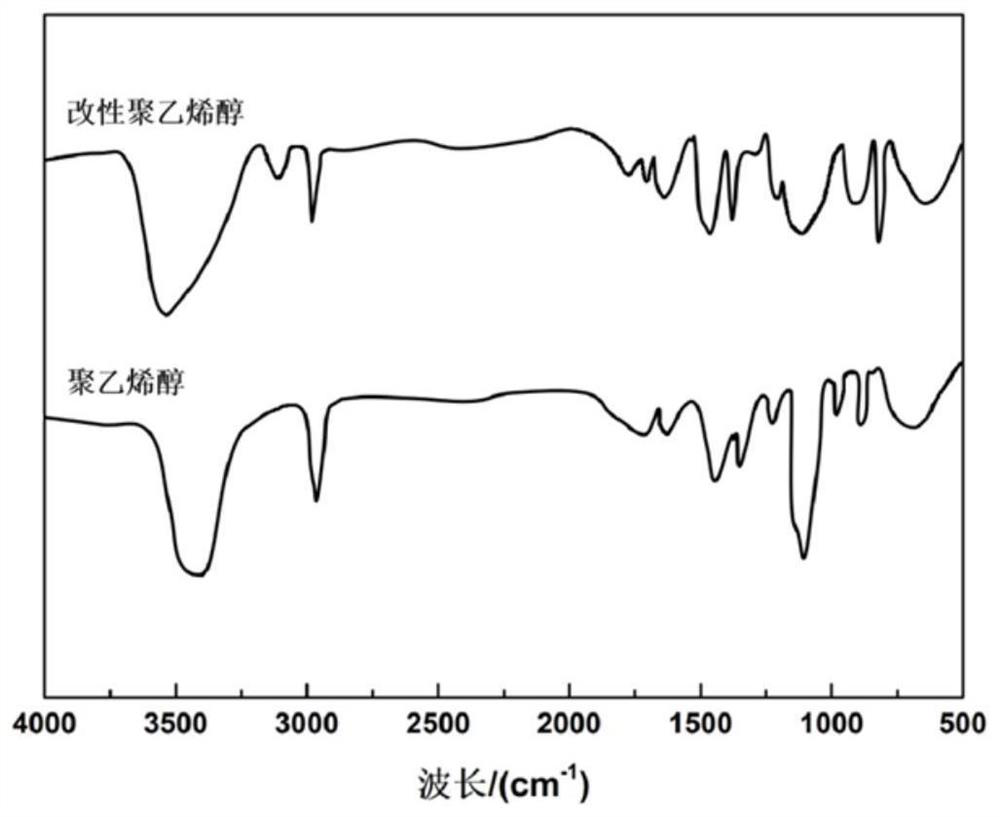

[0035] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0036] Dissolve polyvinyl alcohol in deionized water and swell at room temperature for 2.5h, then heat it up to 90°C to dissolve, wherein the concentration of polyvinyl alcohol is 12.5wt%; dissolve benzoyl oxidized paeoniflorin in ethanol until completely dissolved , so that the concentration of benzoyl oxidized paeoniflorin is 0.55wt%; the benzoyl oxidized paeoniflorin solution is added to the polyethanol alcohol solution, wherein the weight ratio of benzoyl oxidized paeoniflorin to polyvinyl alcohol is 1:6, And the temperature was controlled at 90° C., stirred and refluxed, reacted for 3 hours, cooled to room temperature, and dried to obtain modified polyvinyl alcohol.

Embodiment 2

[0038] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0039] Dissolve polyvinyl alcohol in deionized water and swell at room temperature for 3.5 hours, then heat it up to 93°C to dissolve, wherein the concentration of polyvinyl alcohol is 13.7wt%; dissolve benzoyl oxidized paeoniflorin in ethanol until completely dissolved , so that the concentration of benzoyl oxidized paeoniflorin is 0.64wt%; the benzoyl oxidized paeoniflorin solution is added to the polyethanol alcohol solution, wherein the weight ratio of benzoyl oxidized paeoniflorin to polyvinyl alcohol is 1:8, And the temperature was controlled at 93° C., stirred and refluxed, reacted for 4 hours, cooled to room temperature, and dried to obtain modified polyvinyl alcohol.

Embodiment 3

[0041] A preparation method of modified polyvinyl alcohol, comprising the following steps:

[0042] Dissolve polyvinyl alcohol in deionized water and swell at room temperature for 3 hours, then heat it up to 95°C to dissolve, wherein the concentration of polyvinyl alcohol is 15wt%; dissolve benzoyl oxidized paeoniflorin in ethanol until completely dissolved, so that The concentration of benzoyl oxidized paeoniflorin is 0.35wt%; the benzoyl oxidized paeoniflorin solution is added to the polyethanol alcohol solution, wherein the weight ratio of benzoyl oxidized paeoniflorin to polyvinyl alcohol is 1:10, and The temperature was controlled at 95°C, stirred and refluxed, reacted for 2.5 hours, cooled to room temperature, and dried to obtain modified polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com