Automatic leveling structure for walking of walking type drilling machine and control system thereof

An automatic leveling and control system technology, applied in the drilling automatic control system, drilling equipment, earthwork drilling and other directions, can solve the problems of reducing drilling efficiency, strict construction site conditions, and cab inclination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

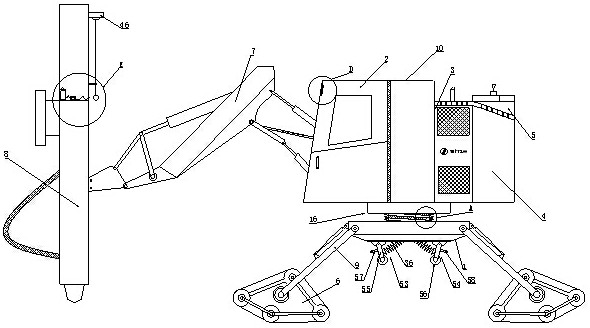

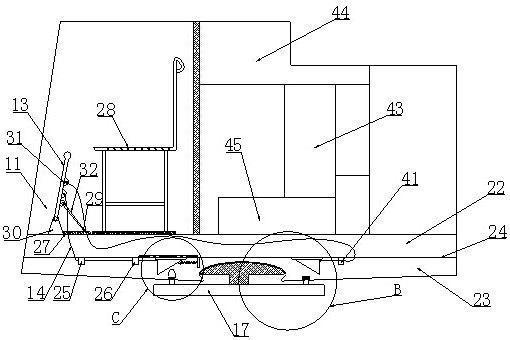

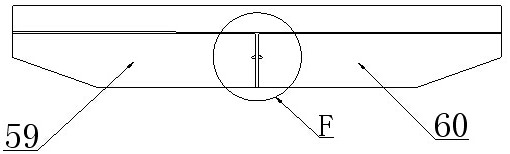

[0030] Such as Figure 1~8 As shown, the walking automatic leveling structure of the walking drilling rig includes conical chassis 1, cab and intelligent control system assembly 2, main pump and power station assembly 3, hydraulic oil tank assembly 4, diesel tank assembly 5, crawler walking assembly 6, telescopic arm assembly 7, mechanical arm assembly 8, outrigger assembly 9 and driving control master box 10, the inside of the cab and intelligent control system assembly 2 is equipped with an automatic leveling device 11 And straightening observation device 12, described automatic leveling device 11 comprises leveling joystick 13, leveling steel wire 14, leveling triangular block and spring one 15, the bottom of described cab and intelligent control system assembly 2 is provided with Leveling base 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com