Pump unit for lifting ore pulp in sea, combined structure and mining lifting system

A technology of pump unit and slurry, which is applied to components of pumping devices for elastic fluids, pump elements, mining minerals, etc., and can solve problems such as reliability, low economy, easy fatigue damage of diaphragms, and immature technology , to achieve stable and reliable pulp suction and discharge process, strong economy and feasibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

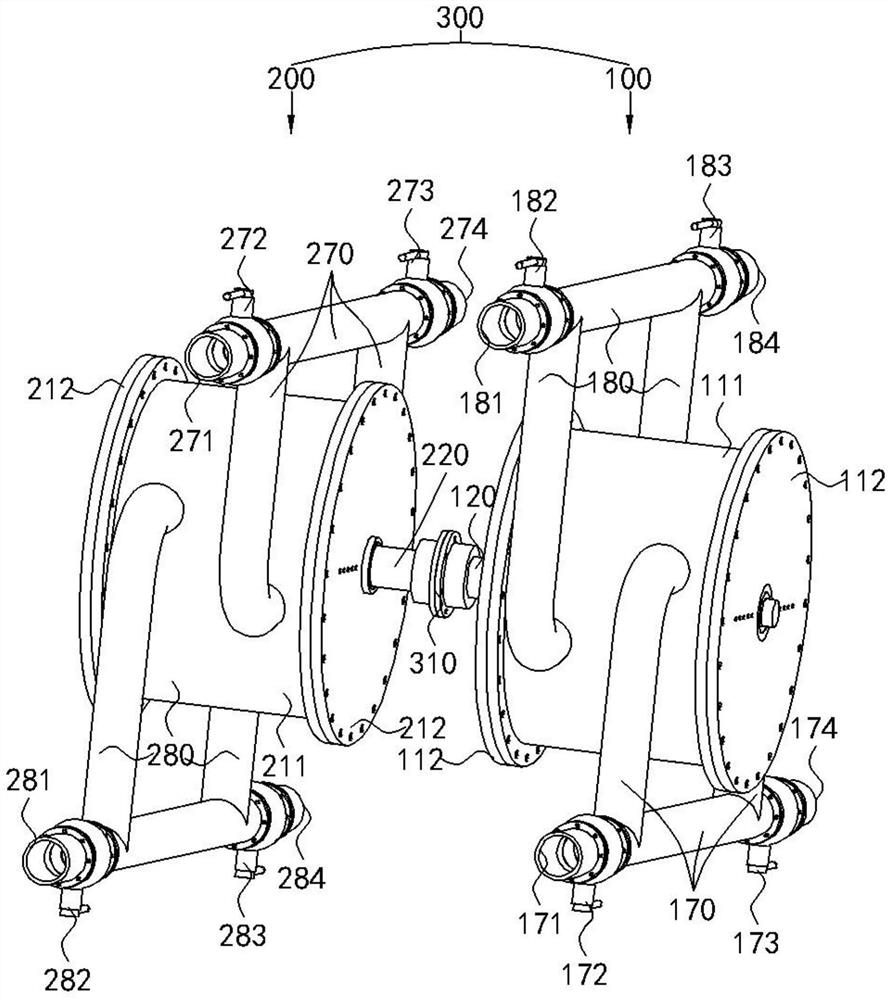

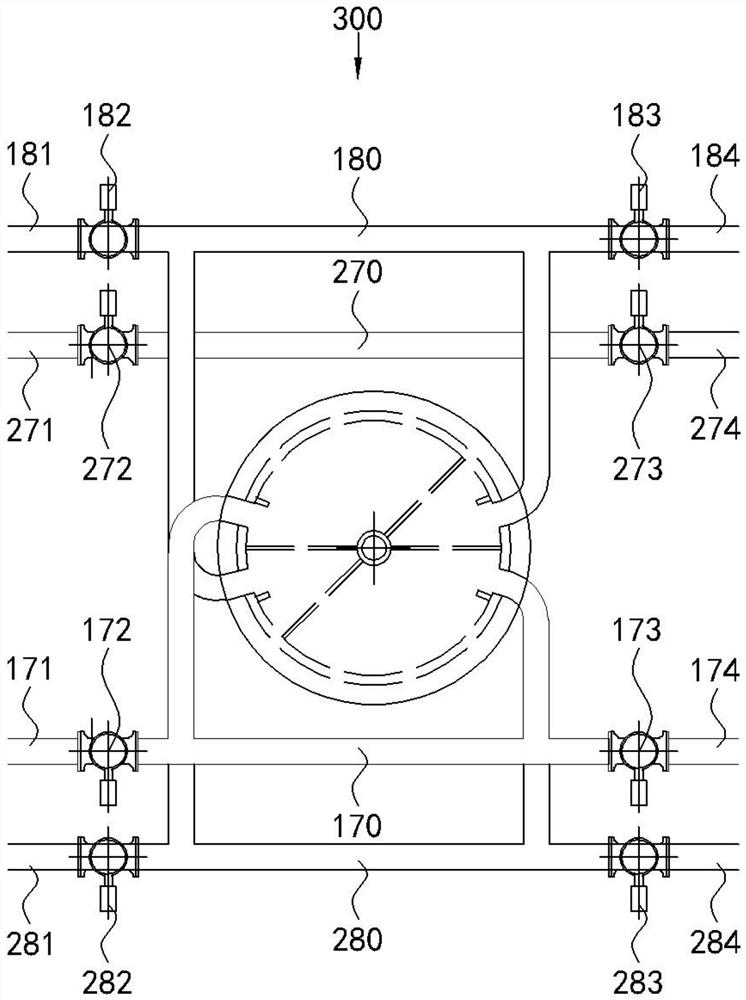

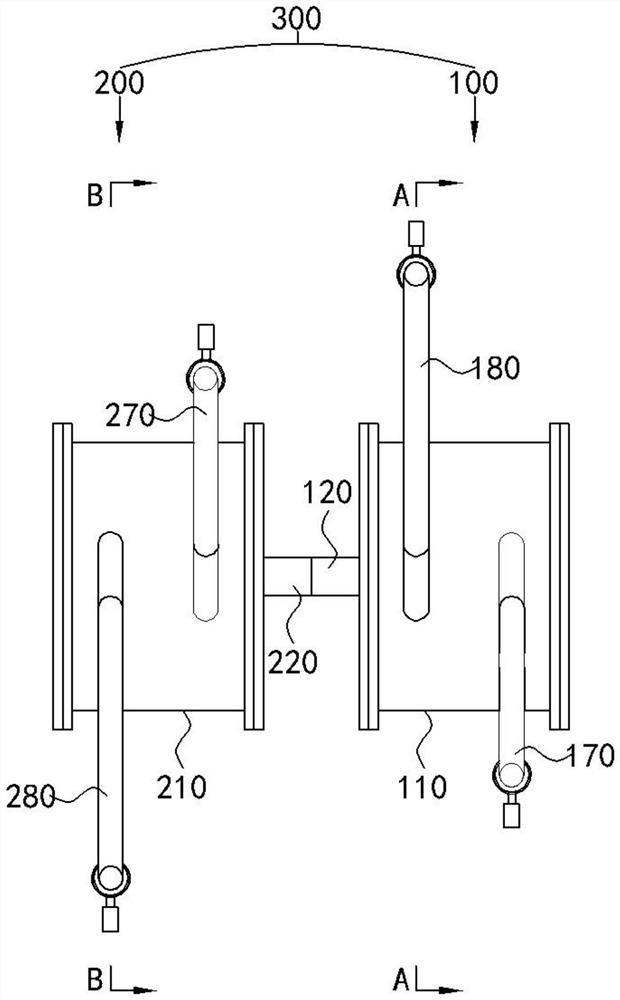

[0061] Such as Figure 1 to Figure 7 As shown, in this embodiment, a pump unit for lifting ore slurry in the sea, the pump unit includes m sets of first pump bodies and n sets of second pump bodies, m≥1, n≥1;

[0062] In each set of first pump bodies, each set of second pump bodies,

[0063] The first pump main body and the second pump main body respectively include a housing, and a coaxial and rotatable rotating shaft assembled in the housing, and through k partitions and k blades, separating the inner cavity of the shell into k seawater cavities and k pulp cavities that are independent and alternately distributed, k≥1; wherein,

[0064] The separator is fixedly and sealingly connected with the inner wall of the housing, and is slidingly and sealingly matched with the rotating shaft, and the blade is fixedly and sealingly connected with the rotating shaft, and is slidingly and sealingly matched with the inner wall of the housing;

[0065] The k seawater cavities are connect...

Embodiment 2

[0086] Based on the first embodiment, in order to facilitate the understanding of the present invention, in the second embodiment, m=n=1, k=2 is taken as an example, that is, there is only one set of the first pump body and the second pump body respectively. In the first pump main body and the second pump main body, there are two clapboards and two vanes in the casing respectively, forming two seawater cavities and two ore slurry cavities which are mutually independent and alternately distributed. The details are as follows.

[0087] Such as Figure 1 to Figure 7 As shown, the pump unit of this embodiment includes a set of first pump main body and a set of second pump main body; wherein,

[0088] In the first pump body 100, the first pump body 100 includes a first casing 110 (the first casing 110 includes a first cylinder body 111 and a first end cover 112 sealingly connected to both ends thereof), and coaxial and The first rotating shaft 120 rotatably assembled in the first...

Embodiment 3

[0105] Embodiment 3 is basically the same as Embodiment 2, except that in Embodiment 2, k=2; and in Embodiment 3, k=1. Such as Figure 8 to Figure 11As shown, in the third embodiment, there is only one set of the first pump main body and the second pump main body respectively. In the first pump main body and the second pump main body, there are one partition plate and one vane in the housing respectively. A seawater cavity and a slurry cavity are formed independently of each other. The principle and action process of the third embodiment are the same as those of the second embodiment, and will not be repeated here.

[0106] Embodiment 3 Compared with Embodiment 2, the disadvantage of Embodiment 3 is that, during the operation of the first pump body 100 and the second pump body 200 , the forces are unbalanced and the stability is not strong enough. Therefore, in each set of the first pump body and each set of the second pump body, it is the best choice for k to be an even num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com