Experimental measurement device and method for additional mass matrix between circular and cylindrical members of annular fluid region of reactor

A technology of adding mass and measuring device, applied in the direction of measuring device, testing of machine/structural components, vibration testing, etc., can solve the problems of increasing uncertainty, large difference in results, etc., to increase top weight, save material, increase The effect of safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments will be described in detail below in conjunction with the accompanying drawings.

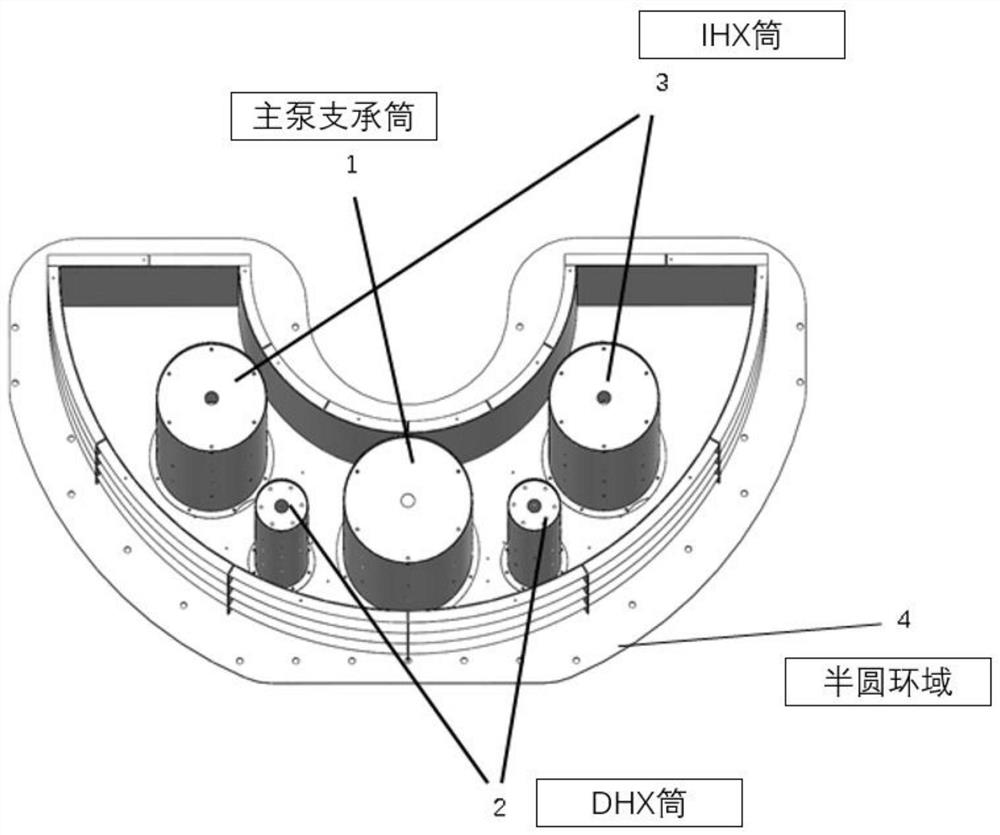

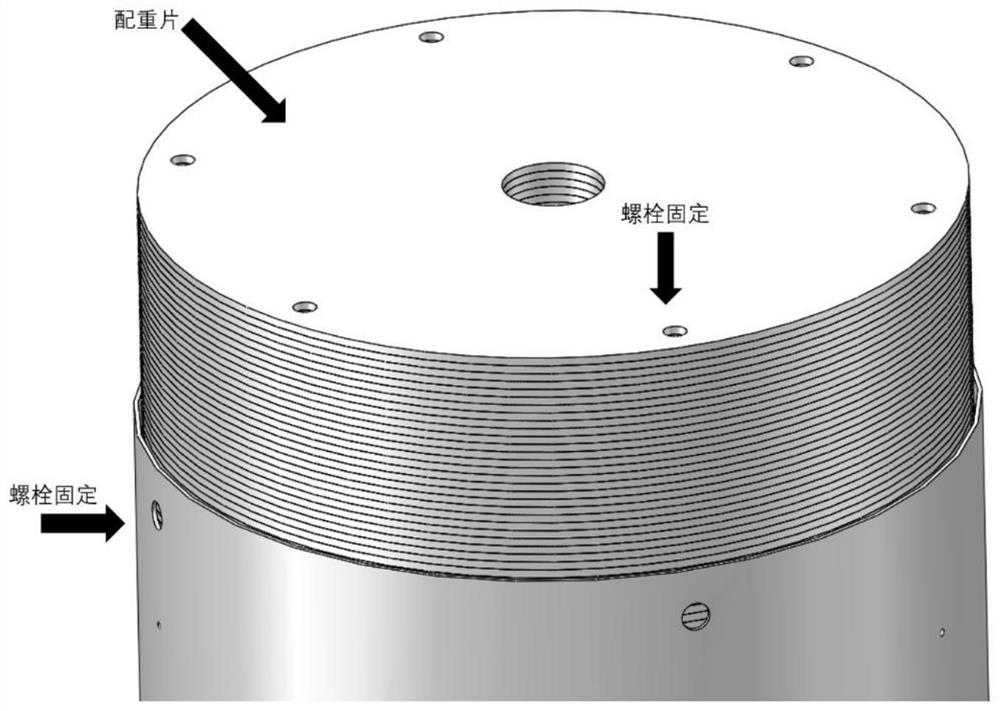

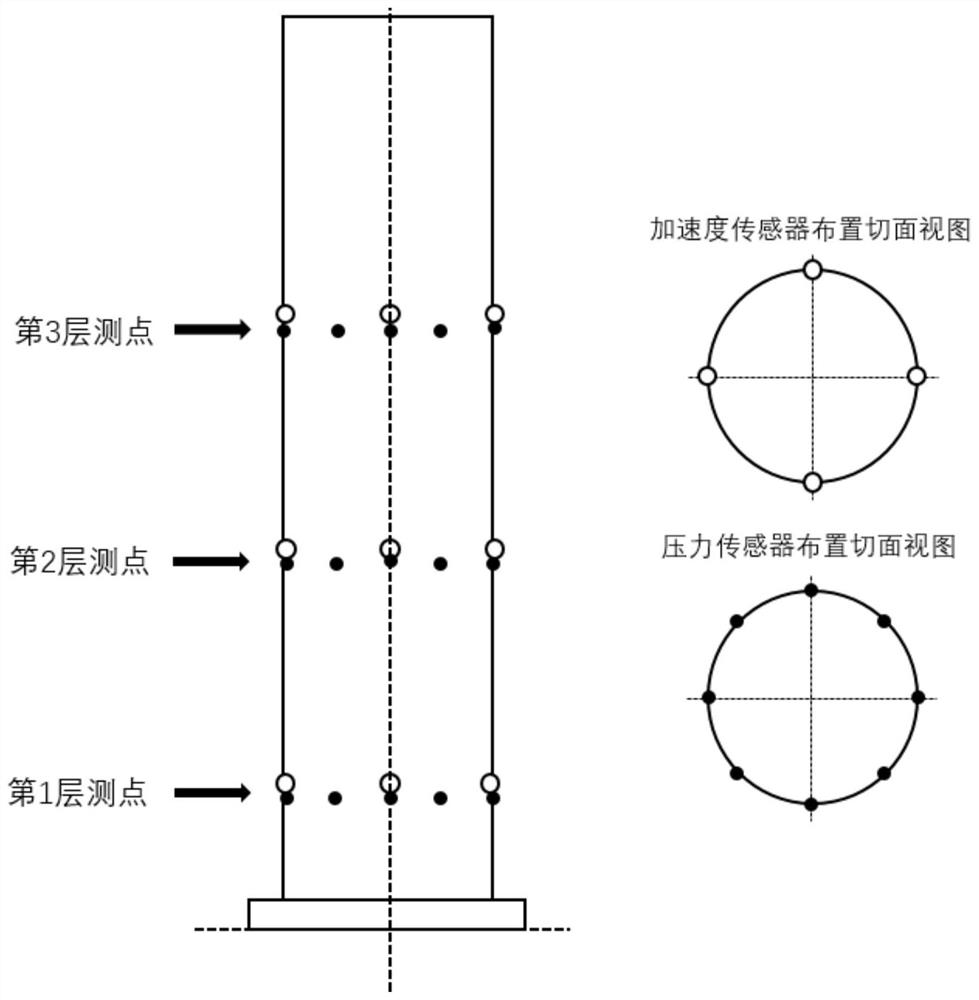

[0036] Many devices in the fast reactor, such as the main pump, intermediate heat exchanger (IHX), independent heat exchanger (DHX), etc., are closely arranged in the ring area of the reactor body, and these devices are equipped with heat shields and support cylinders. Due to the irregular and tight arrangement of these support cylinders, the fluid-structure coupling effect generated by the fluid and equipment in the fast reactor under seismic conditions needs to be evaluated. At present, the finite element method is generally used to model the specific layout, and the vibration characteristics of the model under some specific working conditions are obtained through numerical simulation to evaluate its fluid-solid coupling effect. The finite element modeling method has a certain reference, but generally lacks experimental verification, and because the gap between the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com