Manual eutectic die bonding device, system and method

A patch device and eutectic patch technology, which is applied in the manufacture of electrical components, electric solid devices, semiconductor/solid state devices, etc., can solve the problems of poor quality of eutectic patch and complex structure of automatic chip mounter, etc. To achieve the effect of simple structure, ensuring safety and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following will be further described below with reference to the specific embodiments:

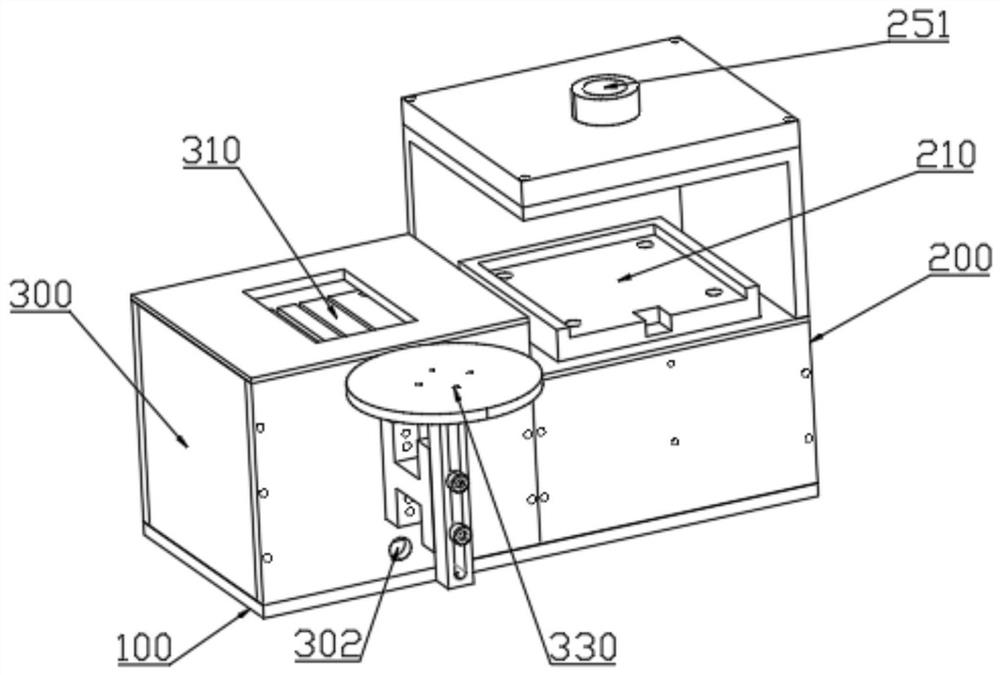

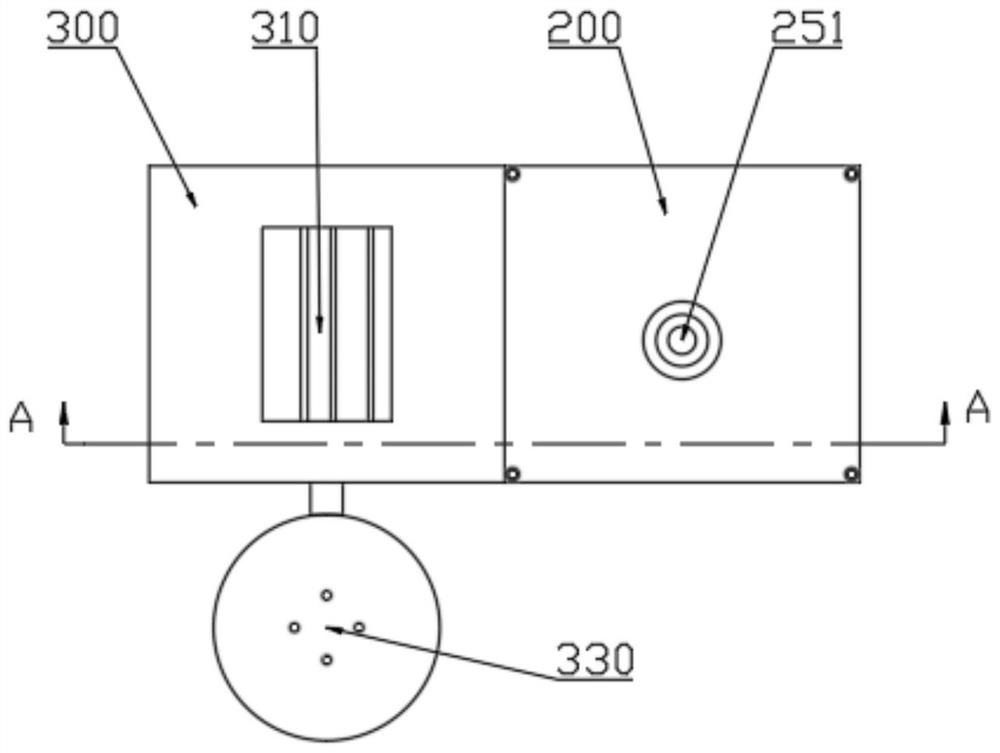

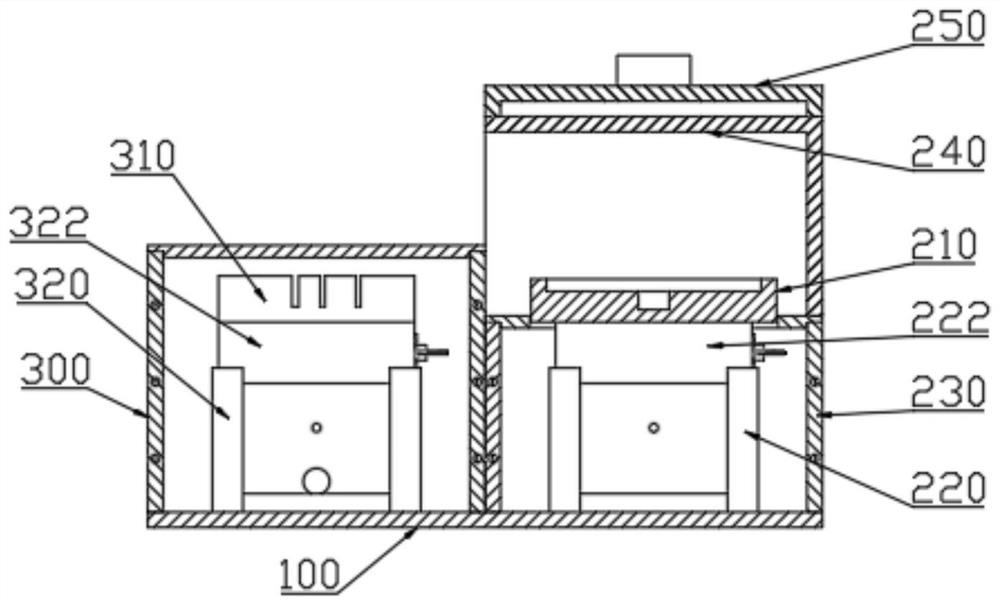

[0055] like figure 1 , image 3As shown, the manual eutectic patch system includes a manual eutectic patch device including a bottom plate 100, a substrate 100 disposed on a parallelial preheating chamber 200 and an eutectry chamber 300; preheating The preheating platform 210 is provided in the chamber 200, and the first heating unit 220 heating the preheating platform 210, and the eutectry chamber 300 is provided, and the second heating unit 320 heated to the eutectic platform 310; preheating The chamber 200 is provided with a first nitrogen injection unit that is injected into nitrogen into the preheating platform 210, and a second nitrogen gas injection unit in which nitrogen gas is injected into nitrogen in the eutectic platform 310 is provided. In this application, the bottom plate 100 is the common bottom plate of the preheating chamber 200 and the eutectic chamber 300, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com