Bimetal composite plate and preparation method thereof

A composite board and bimetal technology, applied in the field of bimetal composite board and its preparation, can solve the problems of poor quality of bimetal composite board, difficulty in large-scale production, low yield, etc., to increase uniformity, enhance bonding strength and Excellent quality and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

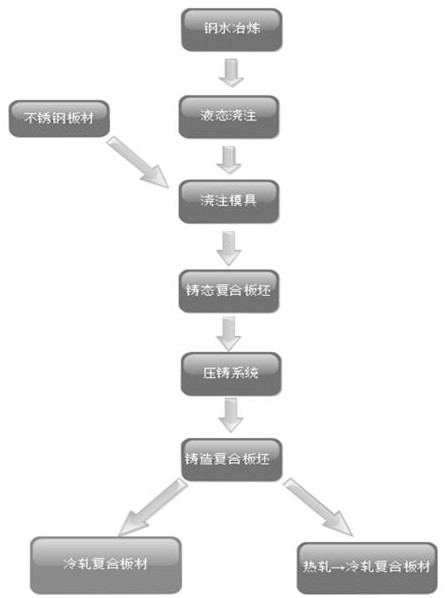

[0029] Such as figure 1 Shown, the preparation method of described a kind of bimetal composite board, it comprises the following steps:

[0030] Pretreatment of the base steel plate;

[0031] Smelting the target carbon steel;

[0032] Preheat the pretreated base steel plate to 900-1000°C, then put it into a mold, and under the protection of an inert gas, cast molten carbon steel into the mold, and combine the molten carbon steel with the base steel plate to form a composite plate rough billet ;

[0033] Apply a pressure of 0.5 to 2 MPa to the rough composite slab and keep the pressure for 2 to 5 hours to form the as-cast composite slab;

[0034] The as-cast composite slab is cold-rolled and / or hot-rolled to obtain a bimetallic composite slab.

[0035] Further, the pretreatment of the base steel plate includes the following steps:

[0036] S1: Soak the base steel plate in sodium hydroxide solution and hydrochloric acid solution for 0.5-1 hour respectively, rinse with deion...

Embodiment 1

[0051] A method for preparing a bimetal composite plate, comprising the following steps:

[0052] Step 1: Pretreatment of the 304 steel plate, the pretreatment includes the following steps:

[0053] S1: Soak the 304 steel plate in the sodium hydroxide solution with a concentration of 0.1mol / L and the hydrochloric acid solution with a concentration of 0.1mol / L for 1 hour respectively, then rinse it with deionized water for 4 times, and then dry the water on the surface of the base steel plate;

[0054]S2: Put the 304 steel plate treated with SS1 into nickel ammonium sulfate at a temperature of 550°C, keep it warm for 45 minutes, and grow a binder film coating with a thickness of about 100nm on the surface of the base steel plate in situ;

[0055] Step 2: Smelting the Q235 carbon steel to make it into molten steel, and adjusting the temperature of the molten steel to 1600°C; the target carbon steel smelting includes the following steps:

[0056] 1): Take Q235 carbon steel and h...

Embodiment 2

[0065] A method for preparing a bimetal composite plate, comprising the following steps:

[0066] Step 1: Pretreatment of the 304 steel plate, the pretreatment includes the following steps:

[0067] S1: Soak the 304 steel plate in the sodium hydroxide solution with a concentration of 0.1mol / L and the hydrochloric acid solution with a concentration of 0.1mol / L for 1 hour respectively, then rinse with deionized water twice, and then dry the water on the surface of the base steel plate;

[0068] S2: Put the 304 steel plate treated with SS1 into nickel ammonium sulfate at a temperature of 650°C, keep it warm for 45 minutes, and grow a binder film coating with a thickness of about 150nm on the surface of the base steel plate in situ;

[0069] Step 2: Smelting the Q235 carbon steel to make it into molten steel, and adjusting the temperature of the molten steel to 1700°C; the target carbon steel smelting includes the following steps:

[0070] 1): Take Q235 carbon steel and heat it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com