Preparation method of in-situ nanoparticle and rare earth coupling reinforced aluminum-based composite material

A technology of nano-particles and composite materials, applied in the field of aluminum-based composite materials, can solve problems such as materials being easily corroded, and achieve the effects of improving strength, corrosion resistance, high-strength plasticity and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

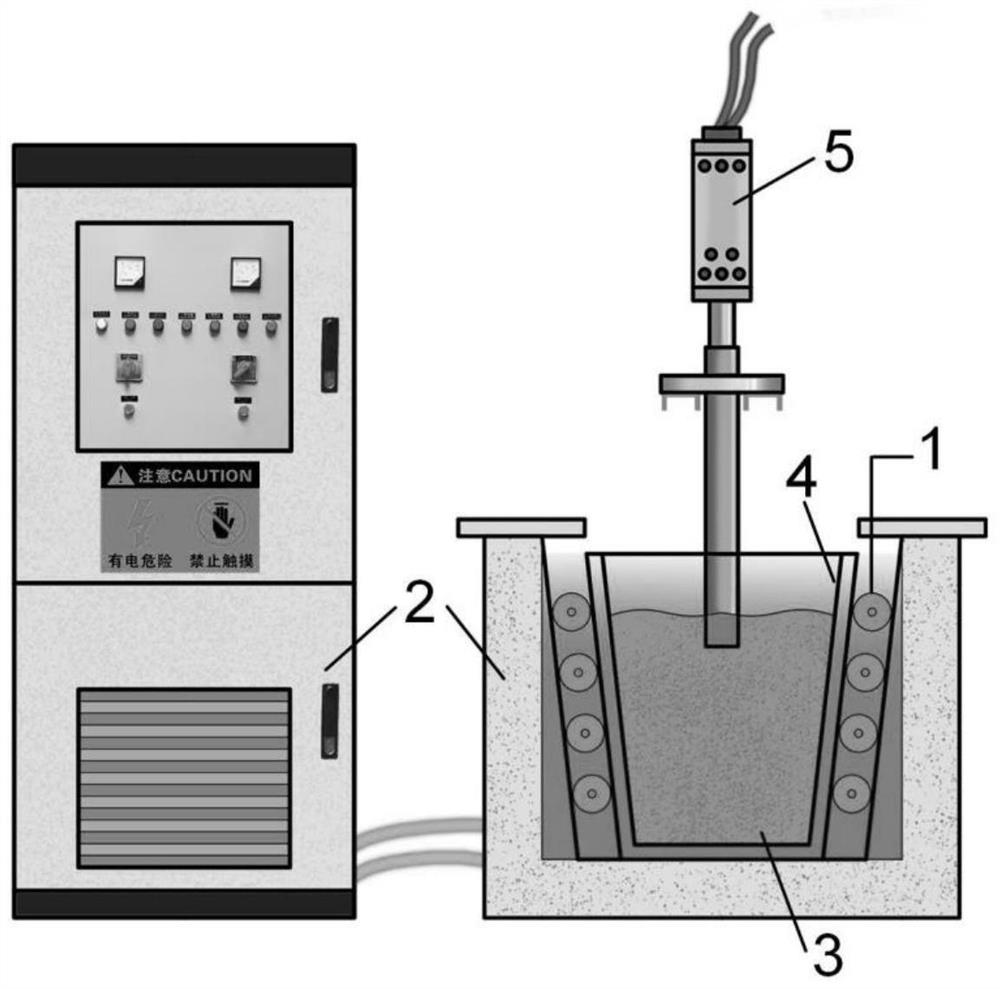

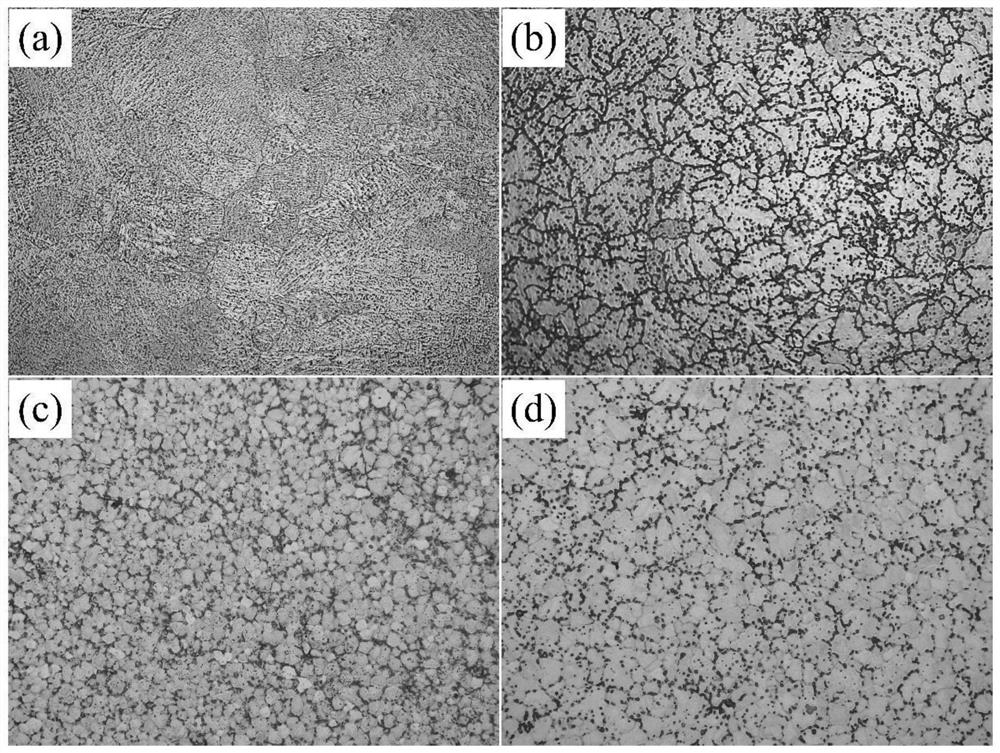

[0027](1) Aluminum alloy casting: Melt 1Kg of aluminum alloy raw material at 790°C and keep it warm for 10 minutes, then raise the temperature of the melt to 850°C, and add the dried reaction powder wrapped in high-purity aluminum foil in batches The body (particle size is less than 100μm, the quality of potassium fluozirconate is 74g, and potassium fluoborate is 80g) enters the melt, and the combination device of low-frequency magnetic field and high-energy ultrasonic field is turned on at the same time (magnetic field: frequency 10Hz, magnetic current 100A; ultrasonic: power 900W, frequency 20kHz) for 30min, after the reaction, remove the scum on the surface of the melt and spray hexachloroethane into the solution for refining, and pour it into a copper mold to obtain 3wt.%ZrB 2 Aluminum matrix composite cast rod.

[0028] (2) Homogenization treatment: the cast rod obtained in step 1 is subjected to head and tail milling to obtain a cast rod with a length of 200 mm. Then pu...

Embodiment 2

[0032] The preparation method is basically the same as in Example 1, except that the reaction product is different, only 145g of Al-20wt.% RE master alloy is added at 750°C, and the reaction of the acoustic-magnetic coupling field is applied for 30 minutes to obtain 0.2wt.% RE material cast rod.

Embodiment 3

[0034] The preparation method is basically the same as that in Example 1, the difference being that the reactant quality is different, not only adding the dried reaction powder wrapped with high-purity aluminum foil (particle size less than 100 μm, potassium fluorozirconate The quality is 74g, potassium fluoroborate is 80g), and the acoustic-magnetic coupling field is applied to react for 30 minutes. After the reaction, the scum on the surface of the melt is removed and hexachloroethane is sprayed into the solution for refining, and then the temperature is lowered to 750°C. Add 145g of Al-10wt.% RE master alloy, apply acousto-magnetic coupling field reaction for 30min to prepare (3wt.%ZrB 2 +0.2wt.% RE) aluminum matrix composite cast rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com