Shock-resistant protective material based on thermoplastic elastomer and preparation method of shock-resistant protective material

A thermoplastic elastomer and protective material technology, applied in the field of organic materials, can solve problems such as non-reusability, poor protective ability of foam pads, and uncomfortable hard shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a preparation method of the thermoplastic elastomer-based impact-resistant protective material described in the above technical solution, comprising:

[0064] The styrene-based thermoplastic elastomer A, the styrene-based thermoplastic elastomer B and polyborosiloxane are mixed, and then pressed and molded to obtain an impact-resistant protective material.

[0065] In the present invention, the above-mentioned preparation process preferably specifically includes the following steps:

[0066] a) mixing the styrene-based thermoplastic elastomer A and the styrene-based thermoplastic elastomer B to obtain a blend;

[0067] b) extruding and mixing the blend and polyborosiloxane through a twin-screw extruder to obtain an extrusion mixed material;

[0068] c) Pressing the extruded mixed material with a flat vulcanizing agent to obtain an impact-resistant protective material.

[0069] Wherein, the types and dosages of the styrene-based ther...

Embodiment 1

[0078] 1. Preparation of polyborosiloxane:

[0079] Using dihydroxy-terminated polydimethylsiloxane (Sigma Aldrich, viscosity 1800-2200 centistokes dihydroxy-terminated polydimethylsiloxane) with a number average molecular weight of 53000 g / mol, boric acid and dihydroxy-terminated polydimethylsiloxane The polydimethylsiloxane at the end was mixed according to the molar ratio of 0.8:1. After stirring and reacting at 120°C for 48 hours, the obtained crude product was filtered in tetrahydrofuran to remove unreacted boric acid (the ratio of tetrahydrofuran to crude product was 10 mL: 1g), and then evaporate the solvent to obtain polyborosiloxane.

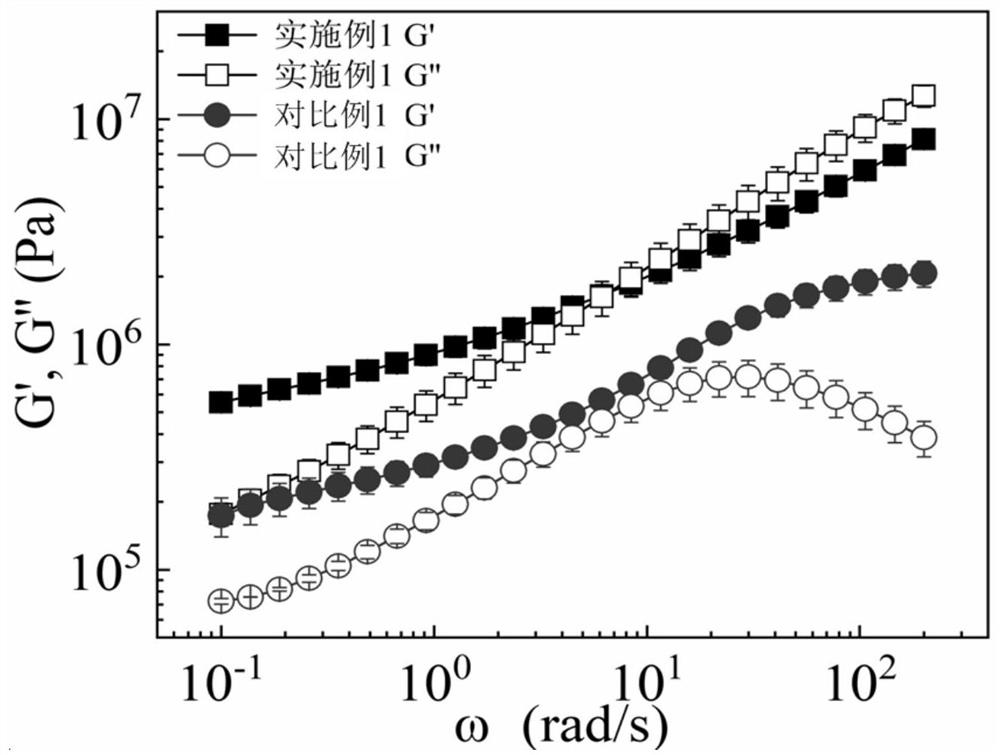

[0080] The reciprocal of the crossover frequency of the storage modulus G' and the loss modulus G" of the above-mentioned polyborosiloxane was measured by linear frequency sweep, and the results showed that the relaxation time of the prepared polyborosiloxane was 0.1s.

[0081] 2. Preparation of impact-resistant protective materials: ...

Embodiment 2

[0090] 1. Preparation of polyborosiloxane:

[0091] Using dihydroxyl-terminated polydimethylsiloxane with a number average molecular weight of 7700 g / mol (Sigma Aldrich, dihydroxyl-terminated polydimethylsiloxane with a viscosity of 65 centistokes), boric acid and dihydroxyl-terminated polydimethylsiloxane Dimethylsiloxane was mixed according to the feeding molar ratio of 1.2:1. After stirring and reacting at 120°C for 48 hours, the obtained crude product was filtered in tetrahydrofuran to remove unreacted boric acid (the ratio of tetrahydrofuran to crude product was 10mL:1g) , and then evaporate the solvent to obtain polyborosiloxane.

[0092] The reciprocal of the crossover frequency of the storage modulus G' and the loss modulus G" of the above-mentioned polyborosiloxane was measured by linear frequency sweep, and the results showed that the relaxation time of the prepared polyborosiloxane was 1.5s.

[0093] 2. Preparation of impact-resistant protective materials:

[0094...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com