A kind of anti-impact protective material based on thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and protective material technology, applied in the field of organic materials, can solve the problems of poor protective ability of foam pads, inability to reuse, discomfort of hard shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a preparation method of the thermoplastic elastomer-based impact protection material described in the above technical solution, comprising:

[0064] After mixing the styrene-based thermoplastic elastomer A, the styrene-based thermoplastic elastomer B and the polyborosiloxane, compression molding is performed to obtain an impact-resistant protective material.

[0065] In the present invention, the above-mentioned preparation process preferably specifically includes the following steps:

[0066] a) mixing the styrenic thermoplastic elastomer A and the styrenic thermoplastic elastomer B to obtain a blend;

[0067] b) extruding and mixing the blend and polyborosiloxane through a twin-screw extruder to obtain an extruded mixed material;

[0068] c) Pressing the extruded mixed material with a flat plate vulcanizing agent to obtain an impact-resistant protective material.

[0069] The types and amounts of the styrene-based thermoplastic el...

Embodiment 1

[0078] 1. Preparation of polyborosiloxane:

[0079] Boronic acid and bishydroxyl-capped polydimethylsiloxane (Sigma Aldrich, bishydroxyl-terminated polydimethylsiloxane with a viscosity of 1800-2200 cSt) with a number average molecular weight of 53,000 g / mol were used to The terminal polydimethylsiloxane was mixed at a molar ratio of 0.8:1, and after stirring and reacting at 120 ° C for 48 h, the obtained crude product was filtered in tetrahydrofuran to remove unreacted boric acid (the consumption ratio of tetrahydrofuran and the crude product was 10 mL: 1 g), then evaporate the solvent to dryness to obtain polyborosiloxane.

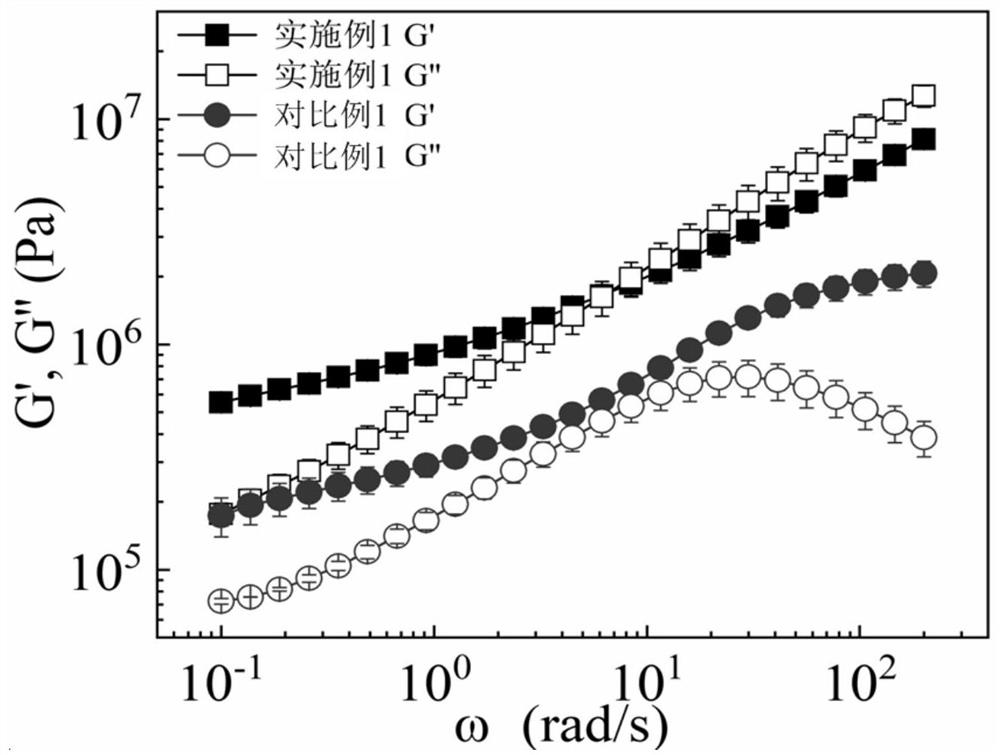

[0080] Linear frequency sweep was used to test the reciprocal of the crossover frequency of the storage modulus G' and the loss modulus G" of the above-mentioned polyborosiloxane. The results showed that the relaxation time of the prepared polyborosiloxane was 0.1s.

[0081] 2. Preparation of impact-resistant protective materials:

[0082] raw material...

Embodiment 2

[0090] 1. Preparation of polyborosiloxane:

[0091] The boronic acid and dihydroxy terminated polydimethylsiloxane were combined with dihydroxy terminated polydimethylsiloxane with a number average molecular weight of 7700 g / mol (Sigma Aldrich, dihydroxy terminated polydimethylsiloxane with a viscosity of 65 cSt) The dimethylsiloxane was mixed according to the molar ratio of 1.2:1, and after stirring and reacting at 120 ° C for 48 h, the obtained crude product was filtered in tetrahydrofuran to remove unreacted boric acid (the consumption ratio of tetrahydrofuran and crude product was 10 mL: 1 g) , and then evaporate the solvent to obtain polyborosiloxane.

[0092] A linear frequency sweep was used to test the reciprocal of the crossover frequency of the storage modulus G' and the loss modulus G" of the above-mentioned polyborosiloxane. The results showed that the relaxation time of the prepared polyborosiloxane was 1.5s.

[0093] 2. Preparation of impact-resistant protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com