Low-dielectric epoxy adhesive and preparation method thereof

A technology of epoxy glue and low dielectric, which is applied in the direction of epoxy glue, adhesive, adhesive type, etc., can solve the problems of high dielectric constant and dielectric loss, and achieve low dielectric constant, high room temperature and Effect of High Temperature Adhesive Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

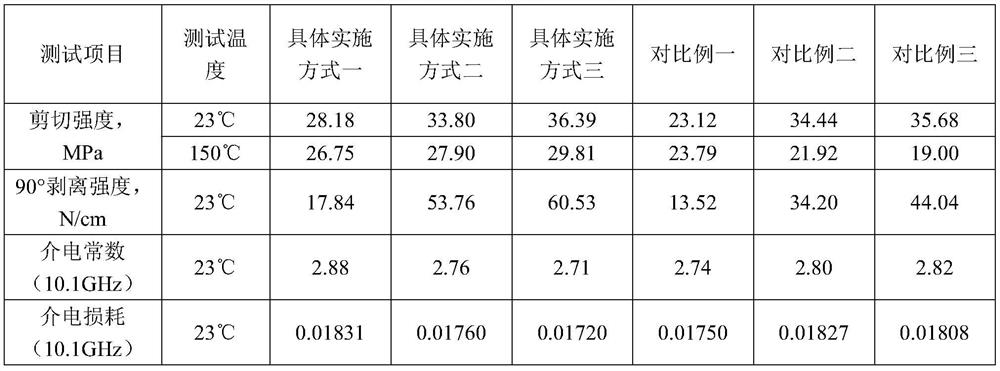

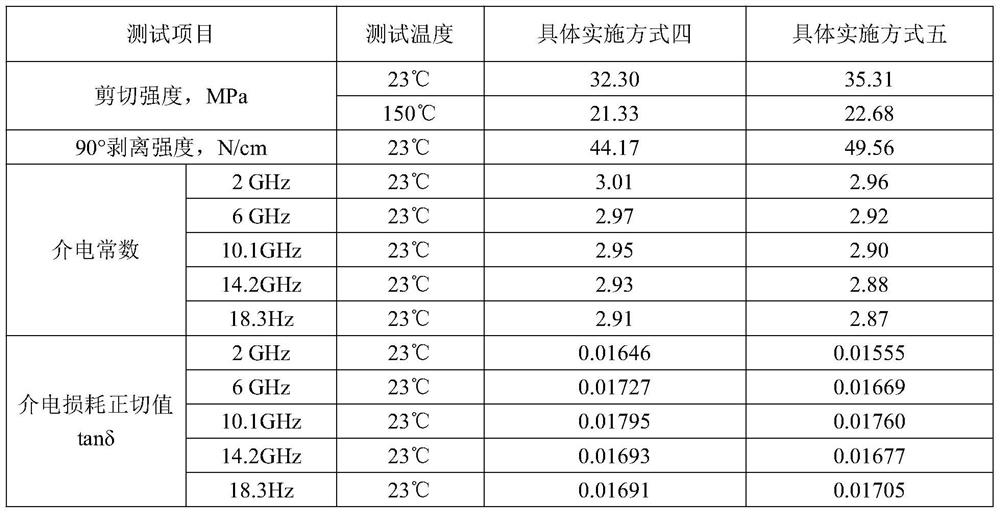

Examples

specific Embodiment approach 1

[0022] A preparation method of low-dielectric epoxy glue, comprising the steps of:

[0023] Step 1. Take 50 parts of bisphenol F epoxy resin and 40 parts of bisphenol E cyanate in parts by weight, and blend them evenly;

[0024] Step 2. Weigh 10 parts of bisphenol F epoxy resin in parts by mass, add 1 part of 2-ethyl-4-methylimidazole, and stir evenly;

[0025] Step 3: Mix the resins in Step 1 and Step 2 evenly to prepare a low-dielectric epoxy glue.

[0026] A low-dielectric epoxy adhesive prepared in this embodiment is used for dielectric samples. The sample size is φ25mm×2mm. The curing process is 100°C for 12 hours, and then 150°C for 12 hours.

specific Embodiment approach 2

[0028] A preparation method of low-dielectric epoxy glue, comprising the steps of:

[0029] Step 1. Weigh 50 parts of bisphenol F epoxy resin and 40 parts of bisphenol E cyanate in parts by weight, blend them evenly, then add 20 parts of EXL2691 core-shell particles, and put them in a high-speed disperser at 5000-13000r / Min speed dispersion 3 ~ 10min;

[0030] Step 2. Weigh 10 parts of bisphenol F epoxy resin in parts by weight, add 1 part of 2-ethyl-4-methylimidazole, and stir evenly;

[0031] Step 3: Mix the resins in Step 1 and Step 2 evenly to prepare a low-dielectric epoxy adhesive.

[0032] A low-dielectric epoxy adhesive prepared in this embodiment is used for dielectric samples, the sample size is φ25mm×2mm, and the specimen is bonded. The curing process is 100°C for 12h, and then 150°C for 12h.

specific Embodiment approach 3

[0034] A preparation method of low-dielectric epoxy glue, comprising the steps of:

[0035] Step 1. Weigh 50 parts of bisphenol F epoxy resin and 40 parts of bisphenol E cyanate in parts by weight, blend them evenly, then add 30 parts of EXL2691 core-shell particles, and put them in a high-speed disperser at 10000-13000r / Min speed dispersion 3 ~ 10min;

[0036] Step 2. Weigh 10 parts of bisphenol F epoxy resin in parts by weight, add 1 part of 2-ethyl-4-methylimidazole, and stir evenly;

[0037] Step 3: Mix the resins in Step 1 and Step 2 evenly to prepare a low-dielectric epoxy adhesive.

[0038] A low-dielectric epoxy adhesive prepared in this embodiment is used for dielectric samples, the sample size is φ25mm×2mm, and the specimen is bonded. The curing process is 100°C for 12h, and then 150°C for 12h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| 90°peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com